Preparation method of modified BaO-TiO2-Sm2O3 dielectric ceramic

A technology of bao-tio2-sm2o3 and dielectric ceramics, which is applied in the field of preparation of modified BaO-TiO2-Sm2O3 dielectric ceramics, can solve the problems of high sintering temperature of dielectric ceramics, achieve lower sintering temperature, better interaction and increase The effect of high sintered density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a modified BaO-TiO 2 -Sm 2 o 3 A method for preparing a dielectric ceramic, comprising the steps of:

[0022] (1) Take BaO, TiO 2 、Sm 2 o 3 and modifier, wet ball milling for 10 hours, the ball milling medium is distilled water, dried after ball milling; the modifier is MnO with a molar ratio of 1:1:2 2 , MgO and WO 3 Composition; the BaO, TiO 2 、Sm 2 o 3 The molar ratio with modifier is 1:1:1:0.014;

[0023] (2) The mixed powder after the drying of the ball mill is uniformly mixed with PVA and pressed into shape, and the pressure of the shape is 95 MPa; the weight ratio of the mixed powder to the binder is 100:25;

[0024] (3) Sintering in the atmospheric atmosphere after pressing and forming, the sintering temperature is 965 ° C, and the heat preservation is 4 hours;

[0025] (4) Annealing, the annealing temperature is 840 ° C, the time is 4 hours, and the modified BaO-TiO is obtained 2 -Sm 2 o 3 Dielectric ceramics.

[0026] Pe...

Embodiment 2

[0030] This embodiment provides a modified BaO-TiO 2 -Sm 2 o 3 A method for preparing a dielectric ceramic, comprising the steps of:

[0031] (1) Take BaO, TiO 2 、Sm 2 o 3 and modifier, wet ball milling for 12 hours, the ball milling medium is distilled water, dried after ball milling; the modifier is MnO with a molar ratio of 1:1:2 2 , MgO and WO 3 Composition; the BaO, TiO 2 、Sm 2 o 3 The molar ratio with modifier is 1:1:1:0.008;

[0032] (2) The mixed powder after the drying of the ball mill is uniformly mixed with PVA and pressed into shape, and the pressure of the shape is 90 MPa; the weight ratio of the mixed powder to the binder is 100:30;

[0033] (3) Sintering in the atmospheric atmosphere after pressing and forming, the sintering temperature is 950 ° C, and the heat preservation is 5 hours;

[0034] (4) Annealing, the annealing temperature is 820 ° C, the time is 5 hours, and the modified BaO-TiO is obtained 2 -Sm 2 o 3 Dielectric ceramics.

[0035] Va...

Embodiment 3

[0038] This embodiment provides a modified BaO-TiO 2 -Sm 2 o 3 A method for preparing a dielectric ceramic, comprising the steps of:

[0039] (1) Take BaO, TiO 2 、Sm 2 o 3 and modifier, wet ball milling for 15 hours, the ball milling medium is distilled water, dried after ball milling; the modifier is MnO with a molar ratio of 1:1:2 2 , MgO and WO 3 Composition; the BaO, TiO 2 、Sm 2 o 3 The molar ratio of modifier and modifier is 1:1:1:0.020;

[0040] (2) After the mixed powder dried by the ball mill is uniformly mixed with paraffin, it is pressed into shape, and the pressure of the shape is 100 MPa; the weight ratio of the mixed powder to the binder is 100:15;

[0041] (3) Sintering in the atmospheric atmosphere after pressing and forming, the sintering temperature is 980 ° C, and the heat preservation is 3 hours;

[0042] (4) Annealing, the annealing temperature is 860 ° C, the time is 4 hours, and the modified BaO-TiO is obtained 2 -Sm 2 o 3 Dielectric ceramics....

PUM

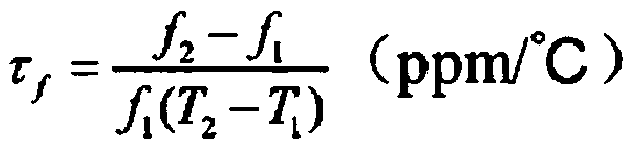

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com