Polyester melt and its preparation method

A technology of polyester melt and precondensation, which is applied in the field of chemical fiber, can solve the problems of poor quality of polyester melt, poor thermal stability, yellow color value, etc. The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

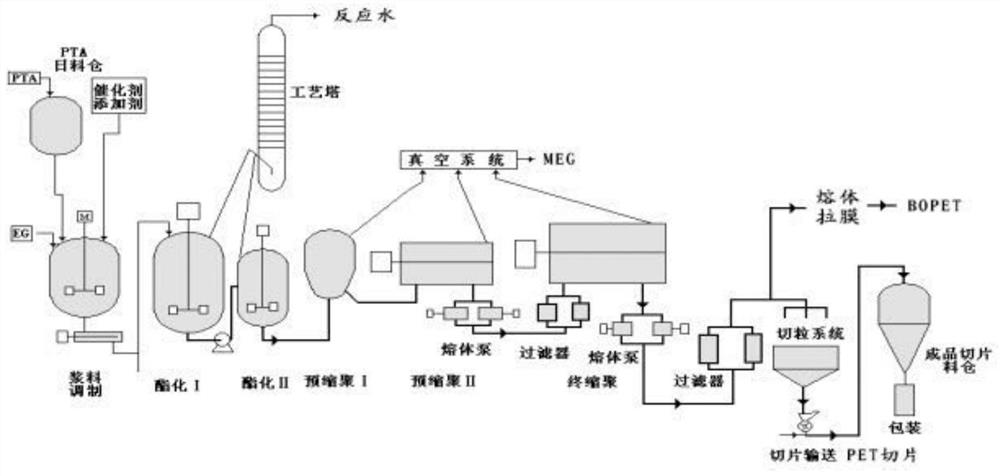

[0076] The preparation method of polyester melt as above may further comprise the steps:

[0077] Mix purified terephthalic acid, ethylene glycol, catalyst, sodium ion modifier and color tone modifier for the first esterification reaction, then add diethylene glycol, phosphorus-containing organic compound stabilizer and magnesium ion modifier The second esterification reaction is carried out, and then the first precondensation reaction, the second precondensation reaction and the final polycondensation reaction are carried out in sequence to obtain a polyester melt.

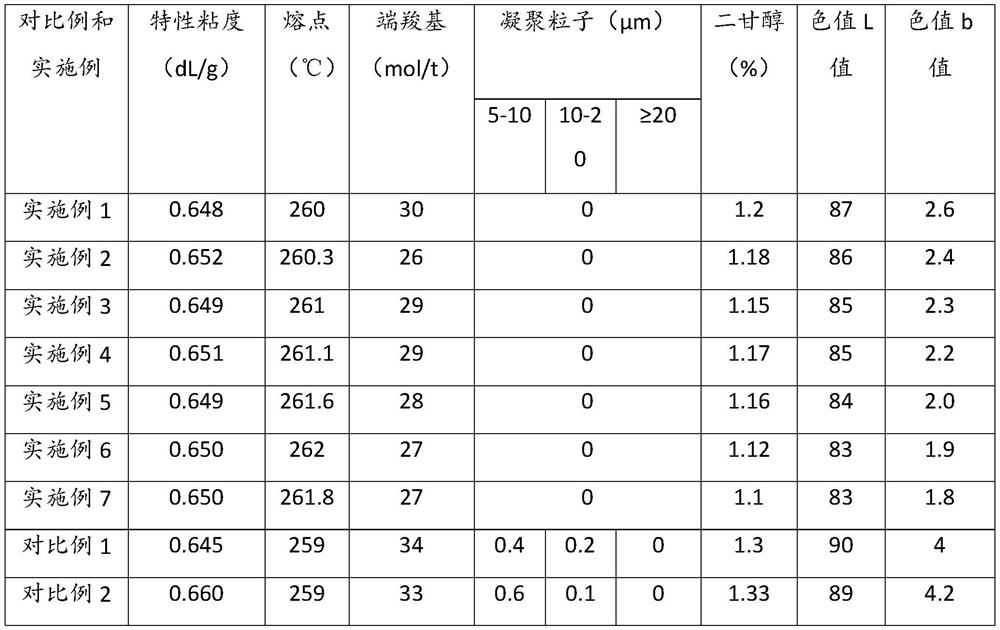

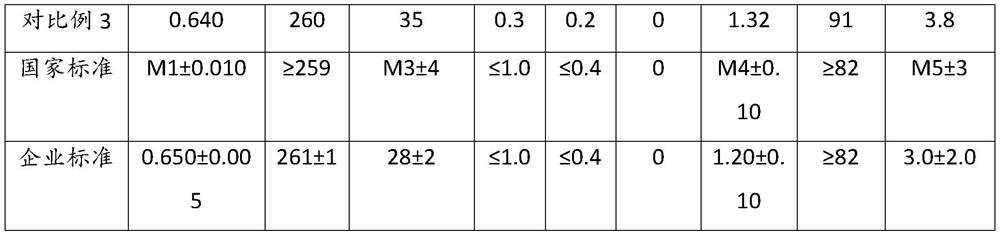

[0078] The present invention adopts the five-pot process, which can effectively avoid the shortcomings of the semi-continuous three-pot process due to the large control range of product indicators (such as intrinsic viscosity controlled at [η] ± 0.010), high carboxyl end groups, and high color value, which cannot meet the BOPET requirements. The demand for 4.5μm ultra-thin films produced by the 8.7-meter direct m...

Embodiment 1

[0121] A polyester melt, mainly prepared from the following raw materials: purified terephthalic acid, ethylene glycol, diethylene glycol, antimony acetate and triethyl phosphoroacetate;

[0122] Among them, in parts by mass, 70 parts of purified terephthalic acid, 18 parts of ethylene glycol, 0.8 parts of diethylene glycol and 0.1 part of antimony acetate;

[0123] The concentration of triethyl phosphoroacetate is 75ppm;

[0124] The viscosity of the polyester melt is 0.640 dL / g.

[0125] Such as figure 1 Shown, the preparation method of described polyester melt, comprises the following steps:

[0126] (a) In the slurry mixing tank, according to a certain proportion, prepare the slurry with purified terephthalic acid, ethylene glycol and antimony acetate, transport it into the first esterification tank through the supply pump, and carry out mass transfer through the agitator Heat transfer, and then heated by the internal coil liquid-phase heat medium and the outer jacket v...

Embodiment 2

[0132] A polyester melt, mainly prepared from the following raw materials: purified terephthalic acid, ethylene glycol, diethylene glycol, ethylene glycol antimony and trimethyl phosphate;

[0133] Among them, in parts by mass, 87 parts of purified terephthalic acid, 35 parts of ethylene glycol, 2 parts of diethylene glycol and 0.6 parts of ethylene glycol antimony;

[0134] The concentration of the trimethyl phosphate is 200ppm;

[0135] The viscosity of described polyester melt is 0.660dL / g;

[0136] The preparation method of described polyester melt, comprises the following steps:

[0137] (a) In the slurry mixing tank, according to a certain ratio, prepare the slurry with purified terephthalic acid, ethylene glycol and ethylene glycol antimony, transport it into the first esterification tank through the supply pump, and carry out the process through the agitator. Mass transfer and heat transfer, and then heated by the internal coil liquid-phase heat medium and the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com