Anisotropic conductive adhesive and conductive film thereof

An anisotropic, conductive adhesive technology, used in conductive adhesives, adhesives, adhesive additives, etc., can solve problems such as insufficient bonding strength, high curing temperature, and lower production costs, reducing the probability of dropping, The effect of improving the bonding strength and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

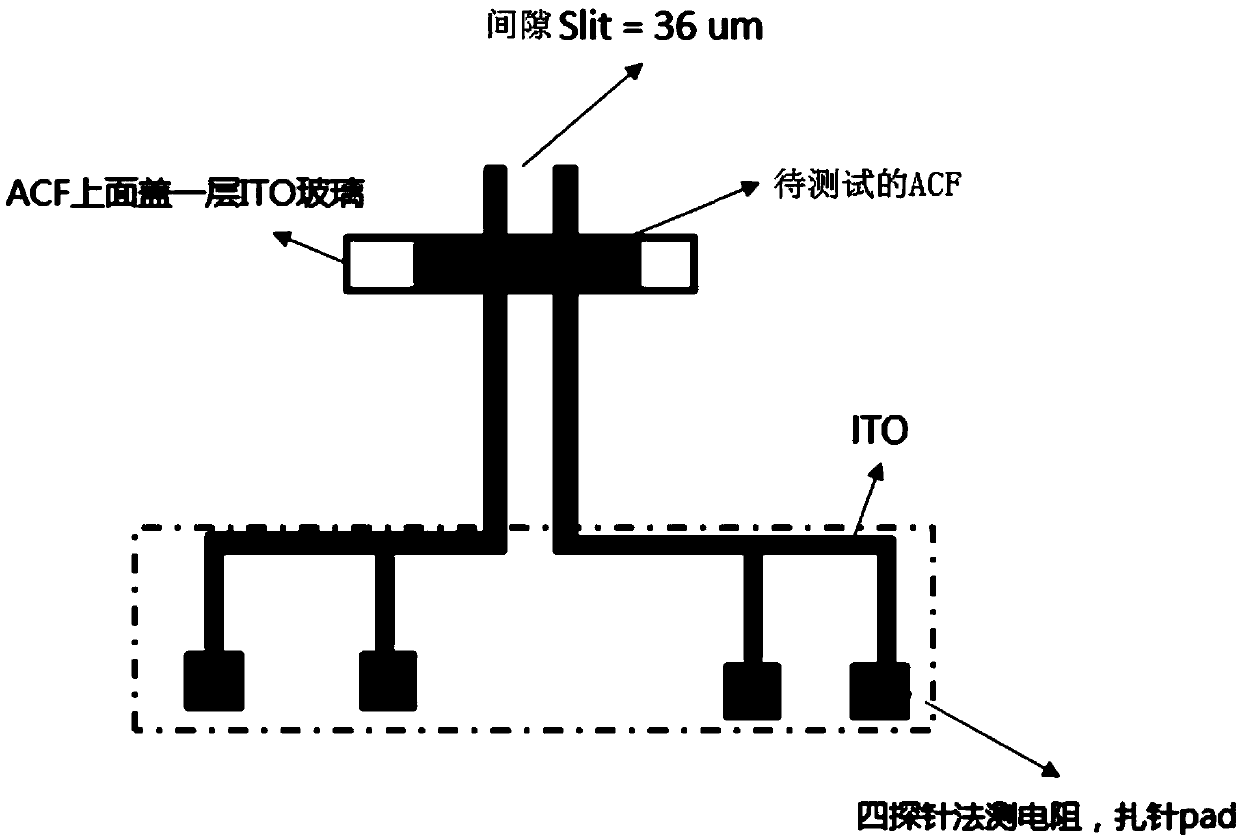

Image

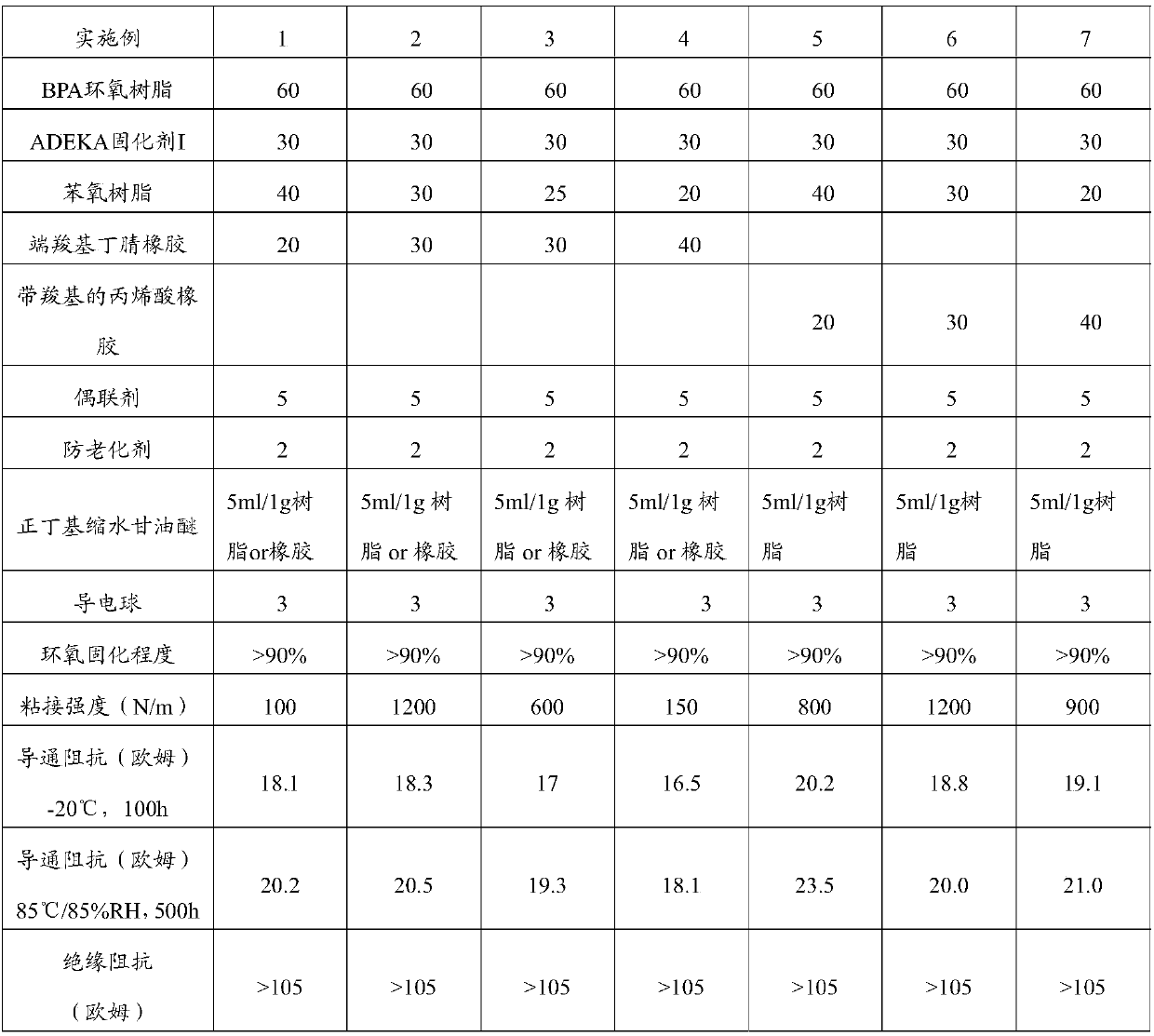

Examples

preparation example Construction

[0054] Further, another embodiment of the present invention provides a method for preparing the above-mentioned conductive film involved in the present invention, comprising the following steps:

[0055] Step1: First disperse the phenoxy resin into the solvent at a predetermined concentration, then add the silane coupling agent, anti-aging agent, and rubber in sequence according to a predetermined ratio, and perform processes such as rubber mixing, stirring, and defoaming, Obtain a pre-mixed rubber material; mix the epoxy resin and curing agent in a predetermined ratio, and quickly add it to the pre-mixed rubber material to obtain a medium-mixed rubber material; then mix the carbon nanotube-modified polystyrene Small balls (CNT Ball) are dispersed in the medium-mixed rubber material in a predetermined ratio, and the processes of mixing, stirring and defoaming are performed again to ensure sufficient mixing;

[0056] Step2: Coat and dry the adhesive material that has been degas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com