Skid-mounted gel dispersion production device and gel dispersion, preparation method and application thereof

A technology for jelly dispersion and production device, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of increasing the cost of deep adjustment and flooding operation of jelly dispersion, and difficult to achieve medium and high temperature bulk freezing. It can not meet the problems of the use of medium-high-temperature and high-salt oil reservoirs, and achieves the effect of facilitating cyclic shearing, improving the safety performance of on-site production, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

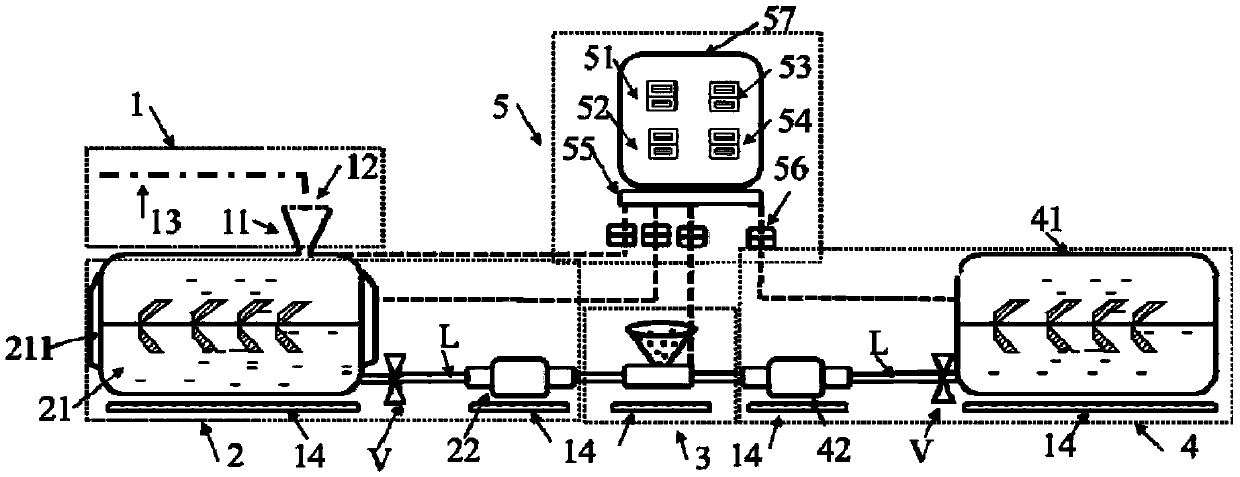

[0051] According to the second aspect of the present invention, there is provided a method for preparing a jelly dispersion, wherein the method is implemented in the above-mentioned equipment. Specifically, the method includes:

[0052] (1) Transport the partially hydrolyzed polyacrylamide and the solution water to the jet mixing system 1, and then jet into the bulk jelly chemical crosslinking reaction system 2 for mixing to obtain an aqueous solution of partially hydrolyzed polyacrylamide;

[0053] (2) The crosslinking agent, coagulant and stabilizer are delivered to the jet mixing system 1, and then jetted to the bulk jelly chemical crosslinking reaction system 2 to contact with the aqueous solution to obtain the bulk jelly gel;

[0054] (3) Utilizing the heating device in the bulk jelly chemical cross-linking reaction system 2 to heat up to a predetermined temperature, and aging the obtained bulk jelly into a glue solution at the predetermined temperature to obtain a pre-jelly disp...

Embodiment 1

[0093] This example is used to illustrate the preparation method of the jelly dispersion of the present invention

[0094] (1) Select a partially hydrolyzed polyacrylamide with a relative molecular weight of 9.85 million and a degree of hydrolysis of 3.8%, add the partially hydrolyzed polyacrylamide and liquid water to the jet 1, jet into the reaction tank 21 and stir for 40 minutes , Formulated into a partially hydrolyzed polyacrylamide solution with a mass fraction of 0.3%.

[0095] (2) Add the phenolic resin prepolymer crosslinking agent, triethanolamine accelerator, and thiourea stabilizer to the partially hydrolyzed polyacrylamide and water mixture prepared in step 1 through the jet 1, so that the phenolic resin prepolymer The mass fraction of polymer crosslinking agent is 0.9%, the mass fraction of triethanolamine accelerator is 0.6%, and the mass fraction of thiourea stabilizer is 0.03%. At room temperature, the mixed solution in the reaction tank 21 is stirred and dispersed...

Embodiment 2

[0103] This example is used to illustrate the preparation method of the jelly dispersion of the present invention

[0104] (1) Select the partially hydrolyzed polyacrylamide with a relative molecular weight of 9.05 million and a degree of hydrolysis of 4.5%, add the partially hydrolyzed polyacrylamide and liquid water into the jet 1, jet into the reaction tank 21 and stir for 30 minutes , Formulated into a partially hydrolyzed polyacrylamide solution with a mass fraction of 0.4%.

[0105] (2) Add the phenolic resin prepolymer crosslinking agent, triethanolamine accelerator, and thiourea stabilizer to the partially hydrolyzed polyacrylamide and water mixture prepared in step 1 through the jet 1, so that the phenolic resin prepolymer The mass fraction of polymer crosslinking agent is 1.0%, the mass fraction of triethanolamine accelerator is 0.5%, and the mass fraction of thiourea stabilizer is 0.04%. At room temperature, the mixed solution in the reaction tank 21 is stirred and dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com