Nitrogen-hydrogen mixed plasma cleaning method suitable for substrate circuit

A plasma cleaning and plasma cleaning machine technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of long cleaning time and incomplete removal of oxides, etc., and achieve low process gas consumption, low cost, and high efficiency for operators and the environment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment Cleaning a batch of substrate circuits with the method of the present invention

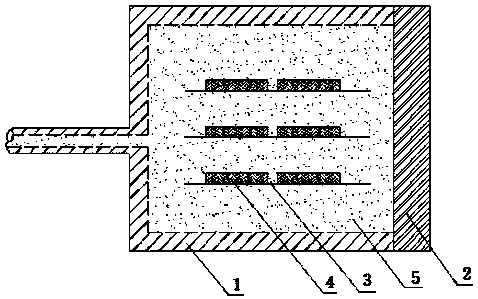

[0019] The first step is to place the substrate circuit to be cleaned in the cleaning chamber of the PINK V15-G plasma cleaning machine. A mesh partition is installed in the cleaning chamber, and the substrate circuit is placed on the partition. Close the cleaning chamber. Chamber door;

[0020] The second step is to introduce a nitrogen-hydrogen gas mixture with a volume ratio of 7%:93%, which is provided by the supplier;

[0021] The third step is to set the power of the RF power supply to 200W, the vacuum degree of the cavity to 160mTorr, and the cleaning time to 120s. The set parameters are controlled by the computer chip;

[0022] Step 4 Start the cleaning program of the plasma cleaning machine for plasma cleaning. After the end, take out the circuit board and close the door of the cleaning chamber.

[0023] The surface of the substrate circuit cleaned by the cleaning met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com