Decoupling controller for suspension force subsystem of five-degree-of-freedom bearingless permanent magnet synchronous motor

A permanent magnet synchronous motor, decoupling controller technology, applied in motor control, motor generator control, AC motor control and other directions, can solve the problems of control performance degradation, parameter perturbation, etc., to achieve simplified structure, fast response speed, The effect of improving suspension control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

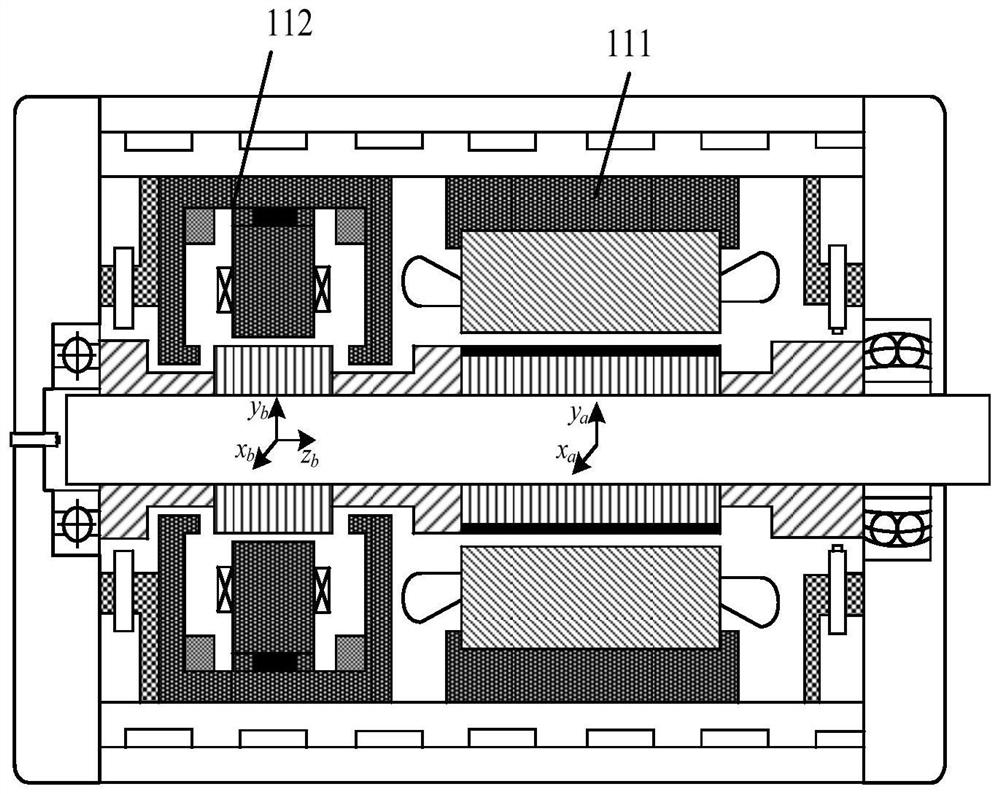

[0015] Such as figure 1 As shown, the five-degree-of-freedom bearingless permanent magnet synchronous motor 11 is composed of a two-degree-of-freedom bearingless permanent magnet synchronous motor 111 and a three-degree-of-freedom AC-DC hybrid magnetic bearing 112, and the two-degree-of-freedom bearingless permanent magnet synchronous motor 111 controls the radial direction of the rotor x a ,y a The displacement of the three-degree-of-freedom AC-DC hybrid magnetic bearing 112 controls the rotor radial x b ,y b and the axial z b displacement.

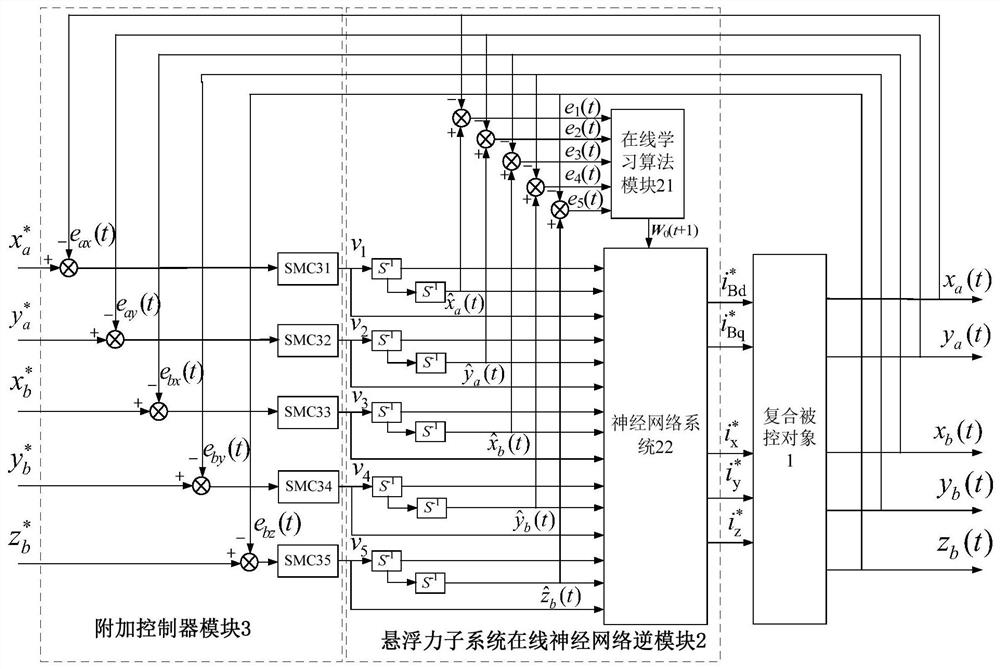

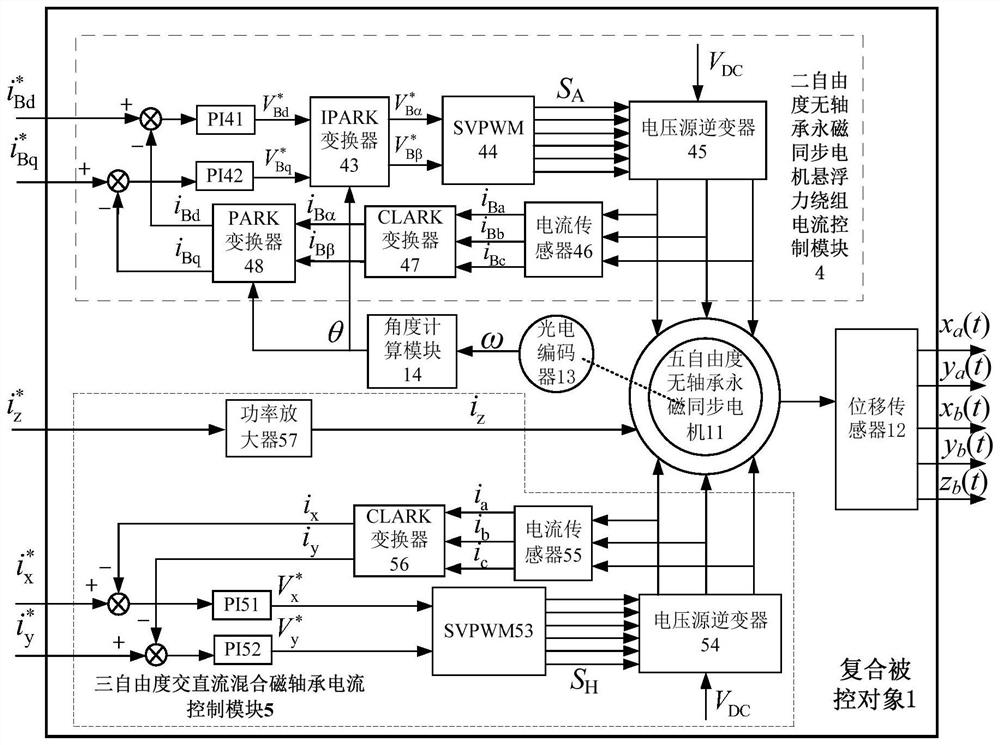

[0016] Such as figure 2 as well as image 3 As shown, it consists of a bearingless permanent magnet synchronous motor 11, a two-degree-of-freedom bearingless permanent-magnet synchronous motor suspension force winding current control module 4, a three-degree-of-freedom AC-DC hybrid magnetic bearing current control module 5, a displacement sensor 12, and a photoelectric encoder 13 And the angle calculation module 14 composes the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com