Making method of pure breed fermented soybean sour soup

A technology of pure-bred fermentation and production methods, applied in the direction of yeast-containing food ingredients, bacteria used in food preparation, and the functions of food ingredients, can solve the problems of wasting soybean clear liquid, etc., and achieve the purpose of delaying female aging, unique flavor, and nutrition. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

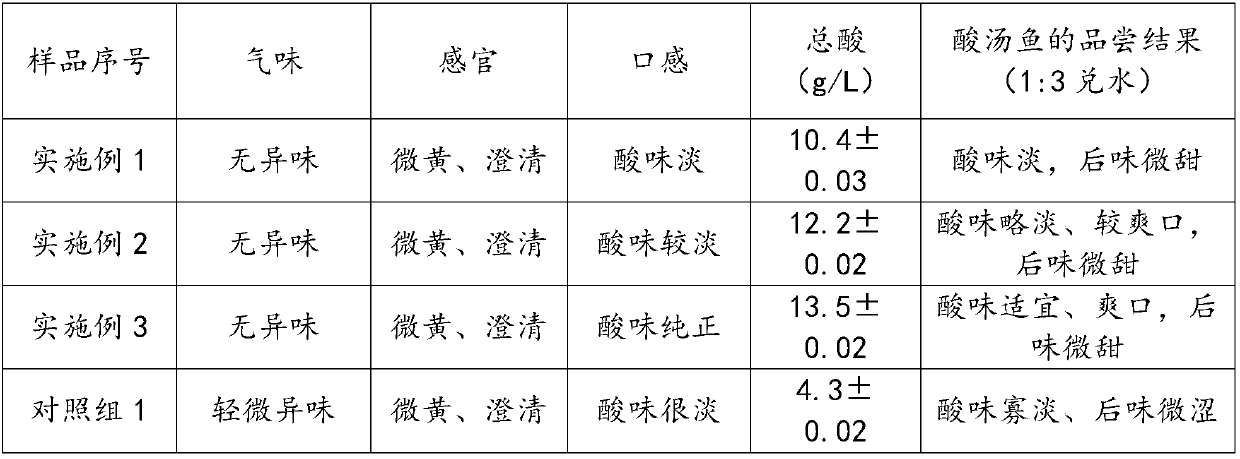

Embodiment 1

[0029] A method for making pure fermented sour bean soup, comprising the following steps: (1) collecting raw materials: collecting bean clear liquid in the process of making bean curd by acid method. (2) Filtration: filter the bean clear liquid through 200 mesh. (3) Add auxiliary materials: add 3% glucose; (4) Sterilize: sterilize at 105° C. for 8 minutes. (5) Inoculate, add 3% mixed strains to the sterilized bean clear liquid (6) Ferment, ferment at 42° C. for 50 h. (7) Filtration: filter through 250 mesh. (8) Sterilization: Sterilize at 85°C for 8 minutes to obtain Soy Sour Soup.

[0030] Wherein, the soy clear liquid collected in the step (1) has an initial acidity of 0.8-1.5 g / L and a sugar content of 1-2 Birx. The particle diameter after filtering in the step (2) is 2-3um. The initial reducing sugar after adding glucose in the step (3) is 4-6%. In the step (5), the mixed strain is Lactobacillus rhamnosus: Lactobacillus corn liquid: Lactobacillus paracasei: Kluyveromy...

Embodiment 2

[0032] A method for making pure fermented sour bean soup, comprising the following steps: (1) collecting raw materials: collecting bean clear liquid in the process of making bean curd by acid method. (2) Filtration: filter the bean clear liquid through 200 mesh. (3) Add auxiliary materials: add 2% glucose; (4) Sterilize: sterilize at 108° C. for 5 minutes. (5) Inoculate, add 2.5% mixed strains to the sterilized bean clear liquid (6) Ferment, ferment at 47° C. for 41 hours. (7) Filtration: filter through 250 mesh. (8) Sterilization: Sterilize at 90°C for 6 minutes to obtain Soy Sour Soup.

[0033] Wherein, the soy clear liquid collected in the step (1) has an initial acidity of 0.8-1.5 g / L and a sugar content of 1-2 Birx. The particle diameter after filtering in the step (2) is 2-3um. The initial reducing sugar after adding glucose in the step (3) is 4-6%. In the step (5), the mixed strain is Lactobacillus rhamnosus: Lactobacillus corn liquid: Lactobacillus paracasei: Kluy...

Embodiment 3

[0035] A method for making pure fermented sour bean soup, comprising the following steps: (1) collecting raw materials: collecting bean clear liquid in the process of making bean curd by acid method. (2) Filtration: filter the bean clear liquid through 200 mesh. (3) Add auxiliary materials: add 4% glucose; (4) Sterilize: sterilize at 103° C. for 10 minutes. (5) Inoculate, add 3.5% mixed strains to the sterilized bean clear liquid. (6) Ferment, ferment at 40° C. for 55 hours. (7) Filtration: filter through 250 mesh. (8) Sterilization: Sterilize at 82°C for 10 minutes to obtain Soy Sour Soup.

[0036] Wherein, the soy clear liquid collected in the step (1) has an initial acidity of 0.8-1.5 g / L and a sugar content of 1-2 Birx. The particle diameter after filtering in the step (2) is 2-3um. The initial reducing sugar after adding glucose in the step (3) is 4-6%. In the step (5), the mixed strain is Lactobacillus rhamnosus: Lactobacillus corn liquid: Lactobacillus paracasei: K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com