A hydrophobic modified core-shell catalyst zif-67@sio 2 Method for preparing ka oil by catalytic cyclohexane oxidation

A ZIF-67, core-shell catalyst technology, applied in the direction of oxidation reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve cyclohexane oxidation reaction is difficult to occur, preparation process is complicated, side reactions are difficult to control, etc. problem, to achieve the effect of increased selectivity, expanded application, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

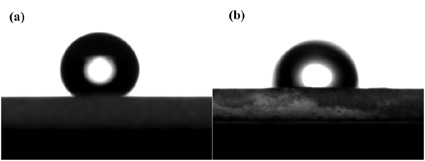

Image

Examples

Embodiment 1

[0035] ZIF-67@SiO 2 Used to catalyze the oxidation reaction of cyclohexane

[0036] (1) Accurately weigh (0.005 mol) Co(NO 3 ) 2· 6H 2 O and (0.04mol) of 2-methylimidazole were dissolved in 80 ml of methanol solution;

[0037] (2) Stir with a glass rod to make it dissolve completely, transfer the two solutions to a round bottom flask (250 ml) after mixing, put in a magnet, and stir at room temperature for 24 h;

[0038] (3) Transfer the solution to a centrifuge tube, centrifuge at 8000 r / min for 3 min, and wash the crystals with methanol until the supernatant is colorless;

[0039] (4) Finally, ZIF-67 was obtained after vacuum drying at 80°C for 24 h;

[0040] (5) Ultrasonic disperse 20 mg of crystals obtained in step (4) in 50 ml of ethanol solution to prepare ZIF-67 ethanol dispersion;

[0041] (6) and use 0.1 mol / L NaOH alkali solution to adjust (5) the pH value of the prepared dispersion to 8~9;

[0042] (7) Add 500mg of cetyltrimethylammonium bromide (CTAB) as a po...

Embodiment 2

[0058] ZIF-67@SiO 2 Used to catalyze cyclohexane oxidation reaction cycle experiment test

[0059] (1) Accurately weigh (0.005 mol) Co(NO 3 ) 2· 6H 2 O and (0.04mol) of 2-methylimidazole were dissolved in 80 ml of methanol solution;

[0060] (2) Stir with a glass rod to make it dissolve completely, transfer the two solutions to a round bottom flask (250 ml) after mixing, put in a magnet, and stir at room temperature for 24 h;

[0061] (3) Transfer the solution to a centrifuge tube, centrifuge at 8000 r / min for 3 min, and wash the crystals with methanol until the supernatant is colorless;

[0062] (4) Finally, ZIF-67 was obtained after vacuum drying at 80°C for 24 h;

[0063] (5) Ultrasonic disperse 20 mg of crystals obtained in step (4) in 50 ml of ethanol solution to prepare ZIF-67 ethanol dispersion;

[0064] (6) and use 0.1 mol / L NaOH alkali solution to adjust (5) the pH value of the prepared dispersion to 8~9;

[0065] (7) Use cetyltrimethylammonium bromide (CTAB) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com