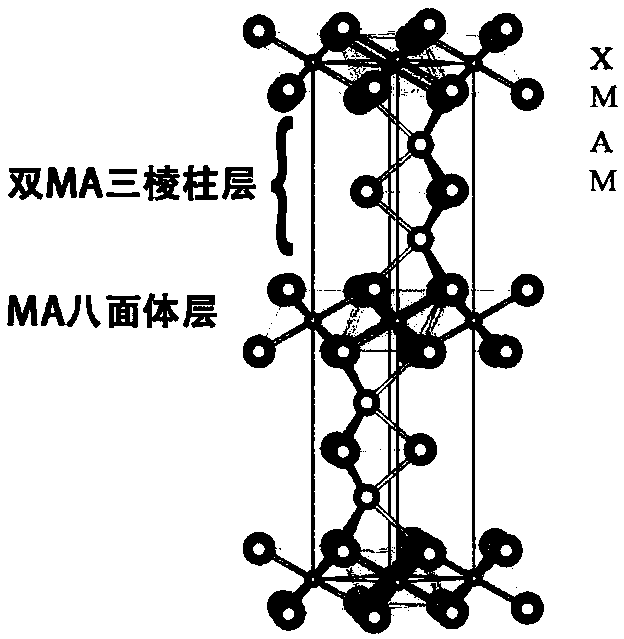

MAX phase-conductive ceramic material and preparation method thereof

A conductive ceramic material and molecular formula technology, applied in the application field, can solve problems such as unsuccessful preparation, and achieve the effects of simple preparation method, high bulk modulus, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

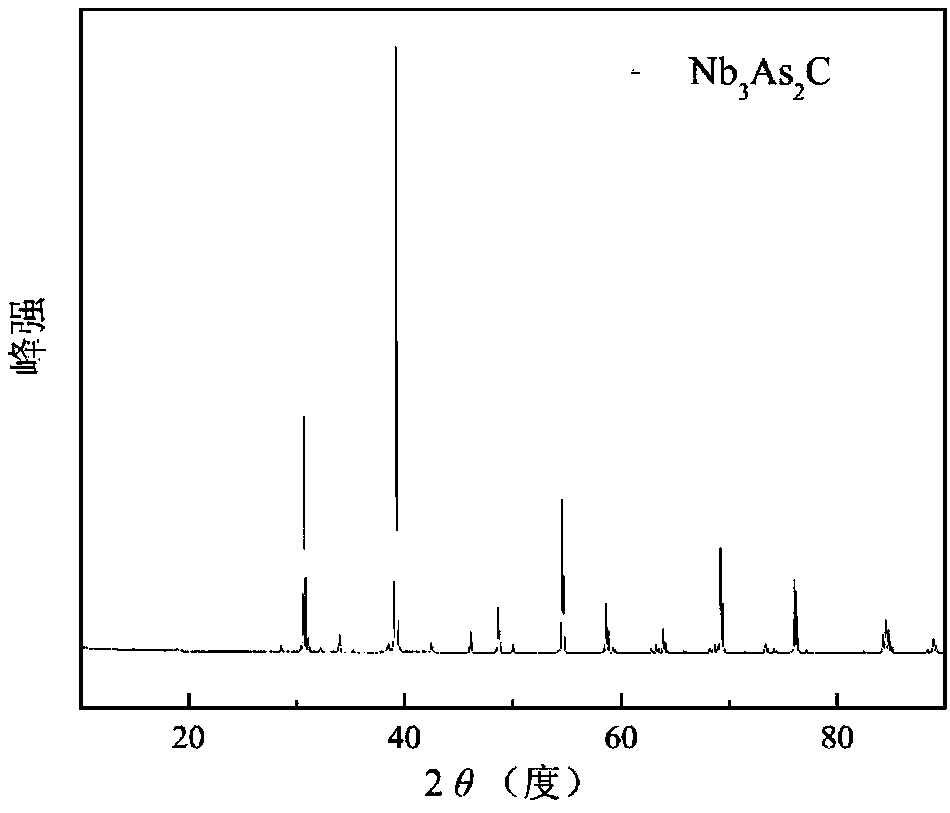

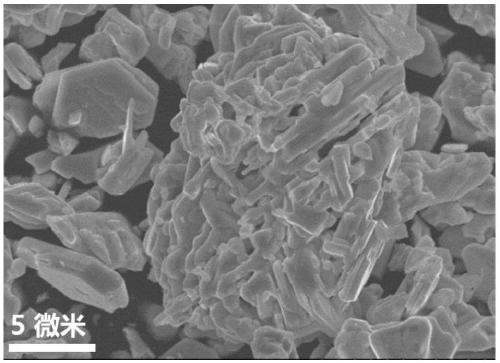

[0025] ① Use Nb powder with a purity of 99%, As powder with a purity of 99%, and graphite powder with a purity of 99%, weigh them according to the ratio of 3:2:1, and grind them under a protective atmosphere such as argon; then mix them evenly The sample was pressed into tablets using a tablet press, the sample was placed in a quartz tube, vacuumed and sealed, and the sample was first calcined: first, it took 5 hours to rise from room temperature to 850 ° C, and kept it for 5 hours, and then cooled naturally .

[0026] ②Take out the sample calcined for the first time, grind it again, press it into tablets, and place the sample in a quartz tube, vacuumize it and seal it with a seal, and then carry out final firing: it takes 5 hours to raise the temperature from room temperature to 1000°C, and then to 200 minutes to 1280°C. Insulate for 15 hours, cool down to room temperature at 3°C per minute to obtain high-purity Nb 3 As 2 C sample. Need to heat up to 1280°C quickly, avo...

Embodiment 2

[0031] ① Use Nb powder with a purity of 99%, P powder with a purity of 99%, and graphite powder with a purity of 99%, weigh them in a ratio of 3:2:1, and grind them under a protective atmosphere such as argon; then mix them evenly The sample is pressed into a tablet using a tablet press, and the sample is placed in a quartz tube, vacuumed and sealed, and the sample is first calcined: first, it takes 48 hours to rise from room temperature to 850°C, keep it warm for 300 minutes, and then cool naturally.

[0032] ②Take out the sample after the initial calcination, re-grind, press into tablets, and place the sample in a quartz tube, vacuumize and seal it, and then carry out final firing: from room temperature to 1000°C in 300 minutes, then to 1280°C in 200 minutes ℃. Insulated for 15 hours, cooled to room temperature at 3°C per minute to obtain Nb 3 P 2 C sample.

[0033] 3. get the Nb prepared by embodiment 2 3 P 2 C sample, adopt X-ray diffractometer to observe its diffra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bulk modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com