Method for preparing high-temperature resistant corrosion-resistant mullite silicon carbide castingmaterial

A technology of mullite silicon carbide and castables, which is applied in the field of mullite silicon carbide castables, can solve the problems of material fire resistance, corrosion resistance reduction, cracks, peeling, etc., and improve chemical corrosion resistance and wear resistance , Improve the preparation efficiency and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

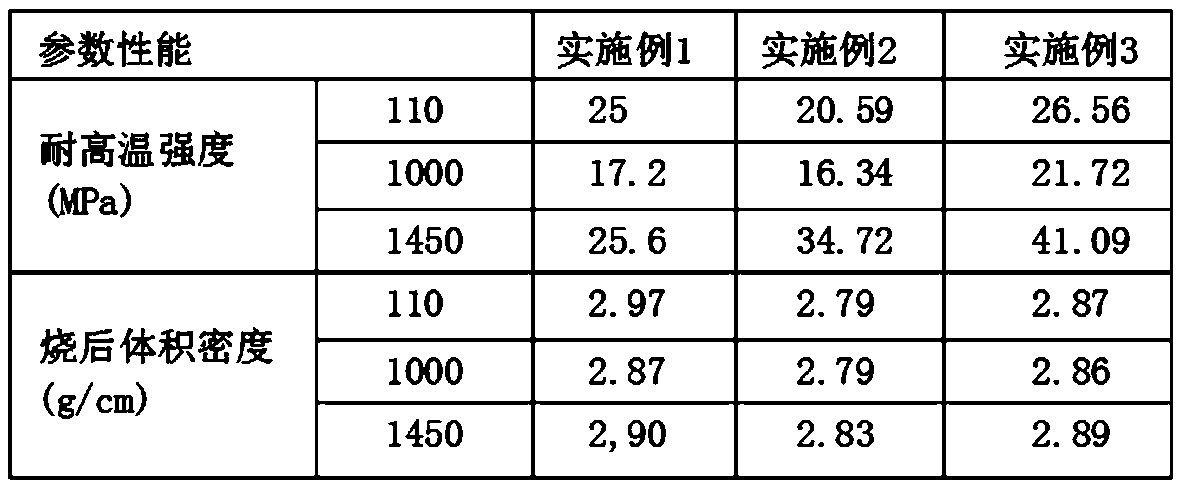

Embodiment 1

[0024] see figure 1 , a method for preparing a high-temperature-resistant and corrosion-resistant mullite silicon carbide castable, comprising the steps of:

[0025] S1. Preparation of mullite silicon carbide castables, based on ingredients and components, in coarse aggregate: mullite 10%, zirconia fiber 3.3%, in medium aggregate: coke gem 12%, silicon carbide 23%, zirconium Stone 1.3%, fine aggregate: mullite 24%, binder: magnesium silicate 13%, phosphate 23%, silicon micropowder 4%, yttrium oxide 7%, and the rest are impurities;

[0026] S2. Crushing, screening, re-crushing, and re-screening the mullite to obtain mullite powder;

[0027] S3, fully mixing the mullite powder prepared in the step S2 with the zirconia fiber particles in proportion to obtain a coarse aggregate;

[0028] S4, crushing, screening, crushing, and re-screening the burnt gemstones to obtain burnt gemstone powder;

[0029] S5, crushing, screening, crushing and re-screening the silicon carbide to obtai...

Embodiment 2

[0040] see figure 1 , a method for preparing a high-temperature-resistant and corrosion-resistant mullite silicon carbide castable, comprising the steps of:

[0041] S1. Preparation of mullite silicon carbide castables. According to the ingredients and components, in the coarse aggregate: mullite 6%, zirconia fiber 3%, in the medium aggregate: coke gem 8%, silicon carbide 20%, zirconium Stone 1%, fine aggregate: mullite 18%, binder: magnesium silicate 13%, phosphate 20%, silicon micropowder 3%, yttrium oxide 6%, and the rest are impurities;

[0042] S2. Crushing, screening, re-crushing, and re-screening the mullite to obtain mullite powder;

[0043] S3, fully mixing the mullite powder prepared in the step S2 with the zirconia fiber particles in proportion to obtain a coarse aggregate;

[0044] S4, crushing, screening, crushing, and re-screening the burnt gemstones to obtain burnt gemstone powder;

[0045] S5, crushing, screening, crushing and re-screening the silicon carbid...

Embodiment 3

[0056] see figure 1 , a method for preparing a high-temperature-resistant and corrosion-resistant mullite silicon carbide castable, comprising the steps of:

[0057] S1. Preparation of mullite silicon carbide castables. According to the ingredients and components, in the coarse aggregate: mullite 8%, zirconia fiber 3.5%, in the medium aggregate: coke gem 12%, silicon carbide 20%, zirconium Stone 1.5%, fine aggregate: mullite 20%, binder: magnesium silicate 10%, phosphate 12%, silicon micropowder 5%, yttrium oxide 8%, and the rest are impurities;

[0058] S2. Crushing, screening, re-crushing, and re-screening the mullite to obtain mullite powder;

[0059] S3, fully mixing the mullite powder prepared in the step S2 with the zirconia fiber particles in proportion to obtain a coarse aggregate;

[0060] S4, crushing, screening, crushing, and re-screening the burnt gemstones to obtain burnt gemstone powder;

[0061] S5, crushing, screening, crushing and re-screening the silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com