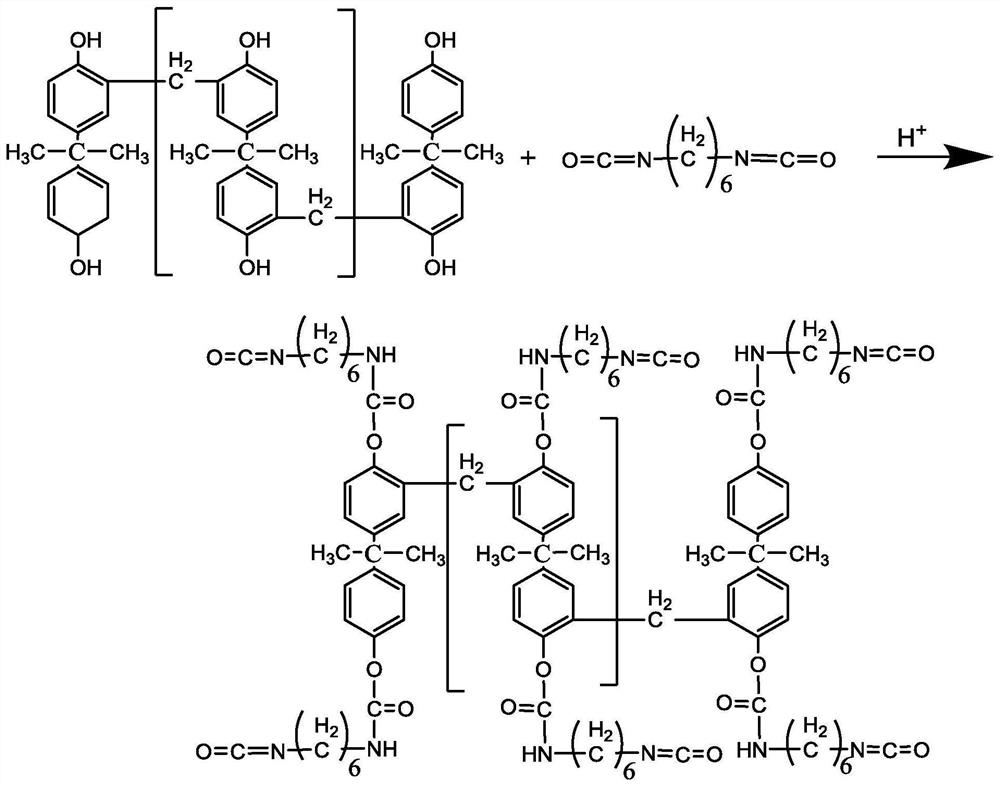

A kind of bisphenol A isocyanate phenolic resin and preparation method thereof

A technology of phenolic resin and isocyanate, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of general water resistance, brittleness, fatigue resistance, heat resistance, and poor impact toughness And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Add 4 g of bisphenol A formaldehyde novolac resin and 20 mL of hexamethylene diisocyanate into a 100 mL three-necked flask, and stir to completely dissolve the bisphenol A formaldehyde novolak resin.

[0037] Step 2, in N 2 Under protection, 60 μL of dibutyltin dilaurate was added into a three-necked flask, and reacted at 15° C. for 2 h. The crude product of bisphenol A isocyanate phenolic resin can be obtained.

[0038] Step 3. Put the crude product into a dialysis bag for dialysis to remove unreacted hexamethylene diisocyanate. The dialysis time is 3 hours to obtain dark yellow bisphenol A isocyanate phenolic resin.

Embodiment 2

[0040] Step 1. Add 4.5 g of bisphenol A formaldehyde novolac resin and 25 mL of hexamethylene diisocyanate into a 100 mL three-necked flask, and stir to completely dissolve the bisphenol A formaldehyde novolak resin.

[0041] Step 2, in N 2 Under protection, 65 μL of dibutyltin dilaurate was added into a three-necked flask, and reacted at 20° C. for 2.5 h. The crude product of bisphenol A isocyanate phenolic resin can be obtained.

[0042] Step 3. Put the crude product into a dialysis bag for dialysis to remove unreacted hexamethylene diisocyanate. The dialysis time is 3 hours to obtain dark yellow bisphenol A isocyanate phenolic resin.

Embodiment 3

[0044] Step 1. Add 5 g of bisphenol A formaldehyde novolac resin and 30 mL of hexamethylene diisocyanate into a 100 mL three-necked flask, and stir to completely dissolve the bisphenol A formaldehyde novolak resin.

[0045] Step 2, in N 2 Under protection, 70 μL of dibutyltin dilaurate was added into a three-necked flask, and reacted at 25° C. for 3 h. The crude product of bisphenol A isocyanate phenolic resin can be obtained.

[0046]Step 3. Put the crude product into a dialysis bag for dialysis to remove unreacted hexamethylene diisocyanate. The dialysis time is 4 hours to obtain a dark yellow bisphenol A isocyanate phenolic resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com