A hot-melt optical adhesive film suitable for automatic bonding and its preparation method

An optical glue, fully automatic technology, applied in the direction of heat-activated film/sheet, film/sheet without carrier, non-polymer organic compound adhesive, etc., can solve the uneven deformation of the film sheet and the difficulty of tearing the protective film , Weak initial adhesion of the film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

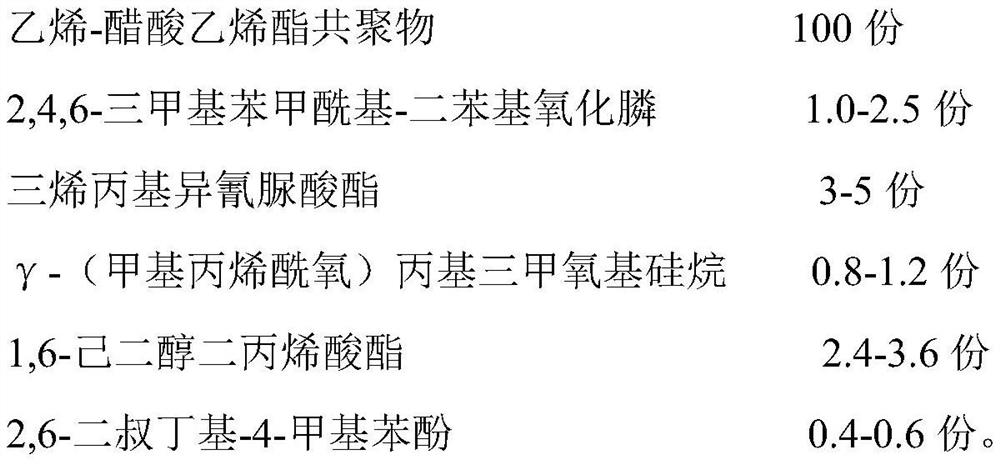

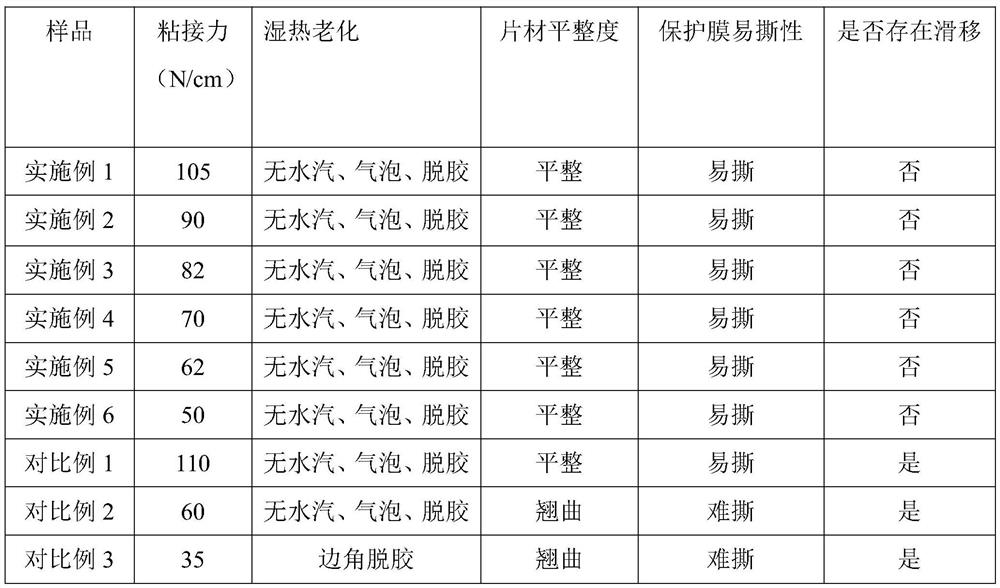

[0030] To 100g of ethylene-vinyl acetate copolymer, add 1.5g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 4g of triallyl isocyanurate, 1g of γ-(methacryloyloxy ) Propyltrimethoxysilane, 3g 1,6-hexanediol diacrylate, 0.5g 2,6-di-tert-butyl-4-methylphenol, and then add 1g ethylene-octene copolymer, through the high-speed mixer Mix evenly, put it into a casting machine, melt it at 110°C, plasticize and extrude, laminate with PET protective film and PE protective film, and make a hot-melt optical adhesive film through stretching, pulling, and winding processes. The surface of the optical film has irregular frosted lines, and the surface static friction coefficient is 0.55.

Embodiment 2

[0032] To 100g ethylene-vinyl acetate copolymer, add 1.0g 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 5g triallyl isocyanurate, 1g γ-(methacryloyloxy ) Propyltrimethoxysilane, 2.4g 1,6-hexanediol diacrylate, 0.6g 2,6-di-tert-butyl-4-methylphenol, then add 2g ethylene-octene copolymer, and stir at high speed Machine mixed evenly, put into the casting machine, melted at 110 ℃, plasticized and extruded, laminated with PET protective film and PE protective film, stretched, drawn, and rolled to obtain a hot-melt optical adhesive film. The surface of the optical film has irregular frosted lines, and the surface static friction coefficient is 0.58.

Embodiment 3

[0034] In 100g ethylene-vinyl acetate copolymer, add 2.5g2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 4g triallyl isocyanurate, 1.2gγ-(methacryloyl Oxygen)propyltrimethoxysilane, 3g1,6-hexanediol diacrylate, 0.5g2,6-di-tert-butyl-4-methylphenol, then add 3g ethylene-octene copolymer, and stir at high speed Machine mixed evenly, put into the casting machine, melted at 110 ℃, plasticized and extruded, laminated with PET protective film and PE protective film, stretched, drawn, and rolled to obtain a hot-melt optical adhesive film. The surface of the optical film is irregular frosted texture, and the surface static friction coefficient is 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com