Preparation method of modified phenolic resin adhesive and product of modified phenolic resin adhesive

A phenolic resin glue and modification technology, which is applied in the preparation of modified phenolic resin adhesives and the field of modified phenolic resin adhesives, can solve the problems of high-value utilization of papermaking waste and low utilization rate, and achieve biomass resources Efficient utilization, conducive to large-scale industrial production, and the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

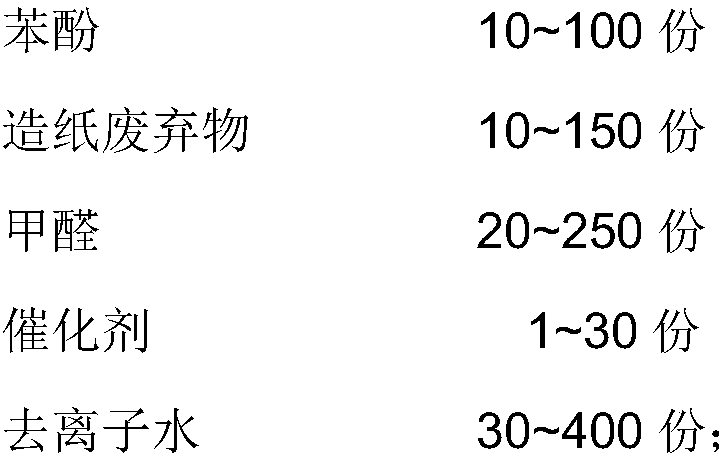

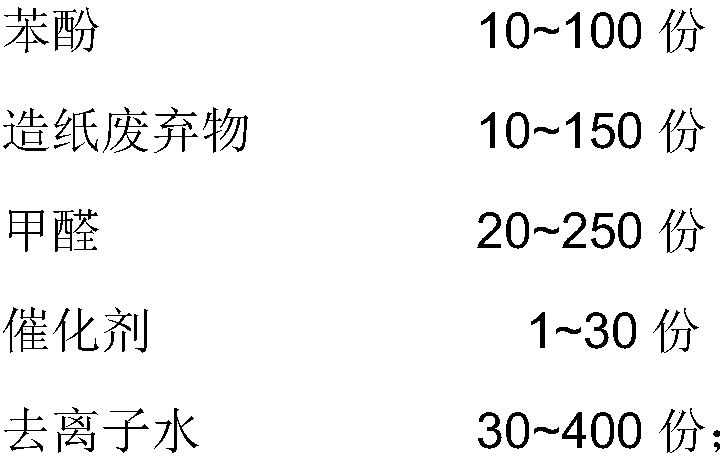

Method used

Image

Examples

Embodiment 1

[0025] Prepare the modified phenolic resin adhesive according to the following steps:

[0026] S1: Add 100g of phenol and 30g of sodium hydroxide into the reaction kettle, start stirring to mix the reactants at the bottom of the kettle evenly, raise the temperature of the reaction system to 50°C within 30 minutes, and keep stirring for 30 minutes;

[0027] S2: Drop the first part of formaldehyde 180g into the reaction kettle at an appropriate dropping rate by using a dropping pump, and keep stirring for 30 minutes;

[0028] S3: The temperature of the reaction system is raised to 80°C within 40 minutes, and then the second part of formaldehyde 60g is dropped into the reactor at an appropriate drop rate using a drop pump, and kept stirring for 50 minutes;

[0029] S4: Add 10g of papermaking waste and 50g of deionized water, keep stirring for 90min;

[0030] S5: Use a dripping pump to drop 10 g of the third part of formaldehyde into the reactor at an appropriate dropping rate, a...

Embodiment 2

[0033] Prepare the modified phenolic resin adhesive according to the following steps:

[0034] S1: Add 50g of phenol and 15g of sodium hydroxide into the reaction kettle, start stirring to mix the reactants at the bottom of the kettle evenly, raise the temperature of the reaction system to 50°C within 30 minutes, and keep stirring for 30 minutes;

[0035] S2: Drop the first part of formaldehyde 140g into the reaction kettle at an appropriate dropping rate by using a dropping pump, and keep stirring for 30 minutes;

[0036] S3: The temperature of the reaction system is raised to 80°C within 40 minutes, and then the second part of formaldehyde 50 g is dropped into the reactor at an appropriate drop rate using a drop pump, and kept stirring for 50 minutes;

[0037] S4: Add 100g of papermaking waste and 50g of deionized water, keep stirring for 90min;

[0038] S5: Use a dripping pump to drop 10 g of the third part of formaldehyde into the reactor at an appropriate dropping rate, ...

Embodiment 3

[0041] Prepare the modified phenolic resin adhesive according to the following steps:

[0042] S1: Add 10g of phenol and 1g of sodium hydroxide into the reaction kettle, start stirring to mix the reactants at the bottom of the kettle evenly, raise the temperature of the reaction system to 50°C within 30 minutes, and keep stirring for 30 minutes;

[0043] S2: Drop the first part of formaldehyde 14g into the reaction kettle at an appropriate drop rate by using a drop pump, and keep stirring for 30 minutes;

[0044] S3: The temperature of the reaction system is raised to 80°C within 40 minutes, and then the second part of formaldehyde 4g is dropped into the reactor at an appropriate drop rate using a drop pump, and kept stirring for 50 minutes;

[0045] S4: Add 150g of papermaking waste and 200g of deionized water, keep stirring for 90min;

[0046] S5: Use the dripping pump to drip the third part of formaldehyde 2g into the reaction kettle at an appropriate dropping rate, and ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com