Strain for stably and efficiently hydrolyzing oil meal and application of strain

A technology of oilseed meal and bacterial strains, applied in the direction of bacteria, microorganism-based methods, microorganisms, etc., can solve the problems of uncontrollable process, long fermentation cycle, cumbersome steps, etc., achieve strong adaptability and tolerance, reduce fermentation cycle, The effect of accelerating the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for stably and efficiently hydrolyzing oilseed meal, the method specifically comprising: mixing oilseed meal, glucose and water in proportion, sterilizing at 121°C for 20 minutes, and adding hydrolyzate to it at a ratio of 5% of the volume of the fermentation broth after cooling. Strain CX-20 was then stirred and fermented at 28° C. for 72 hours in an air-lift fermenter without feeding or changing fermentation conditions to obtain oilseed meal hydrolyzate.

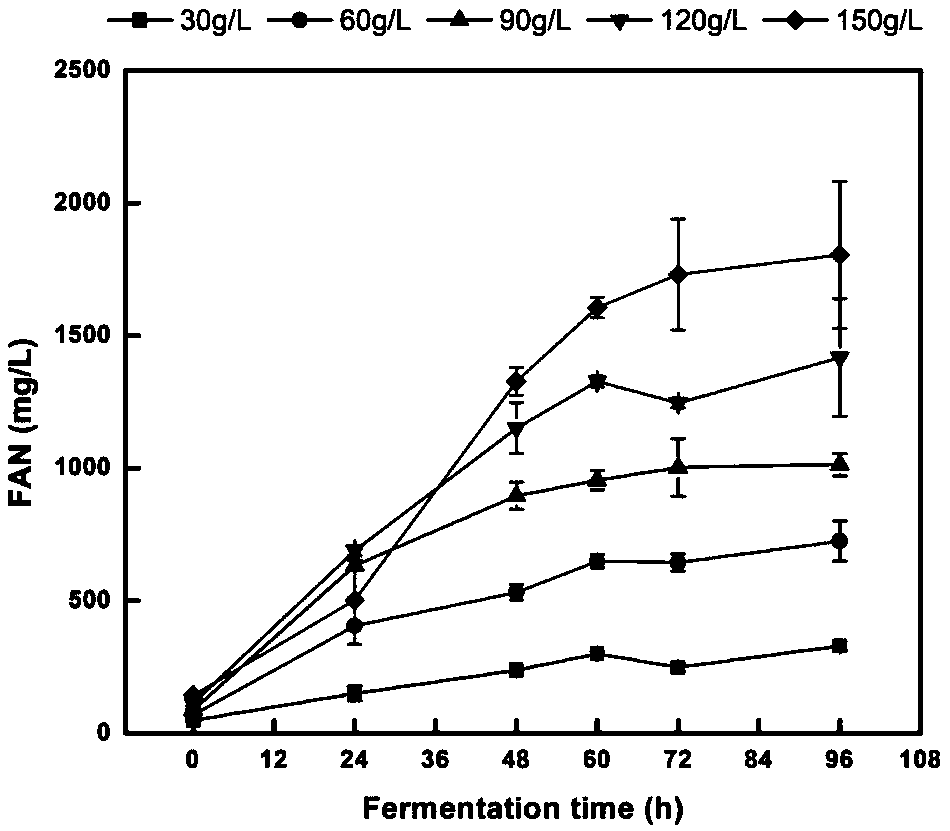

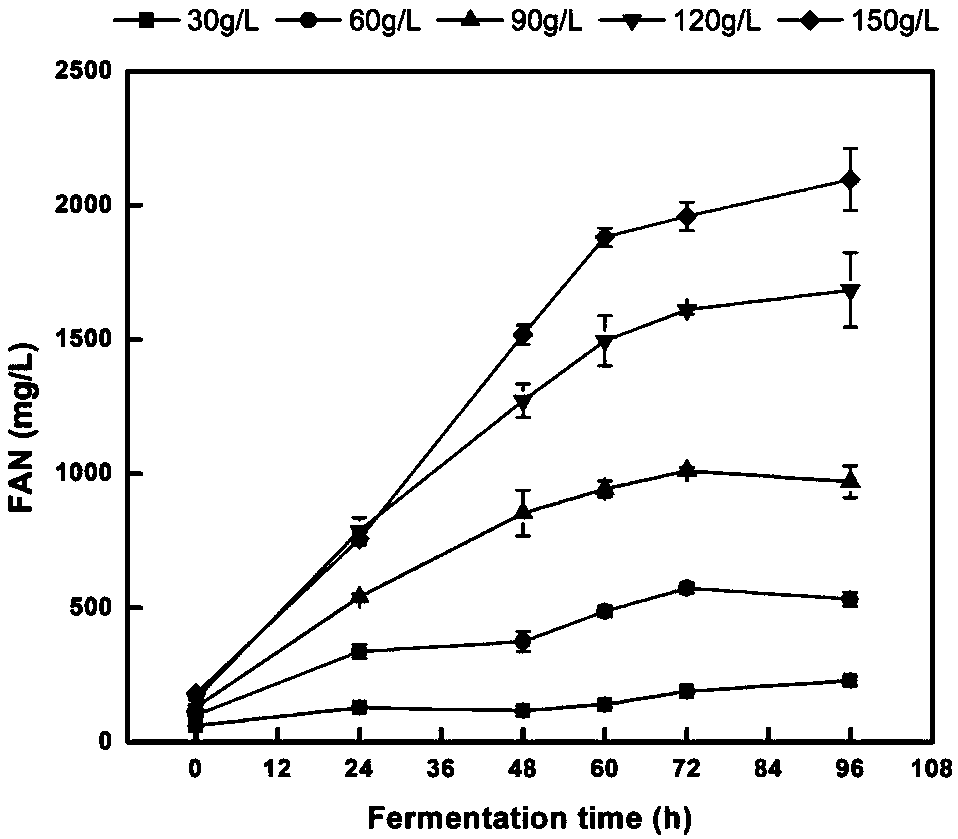

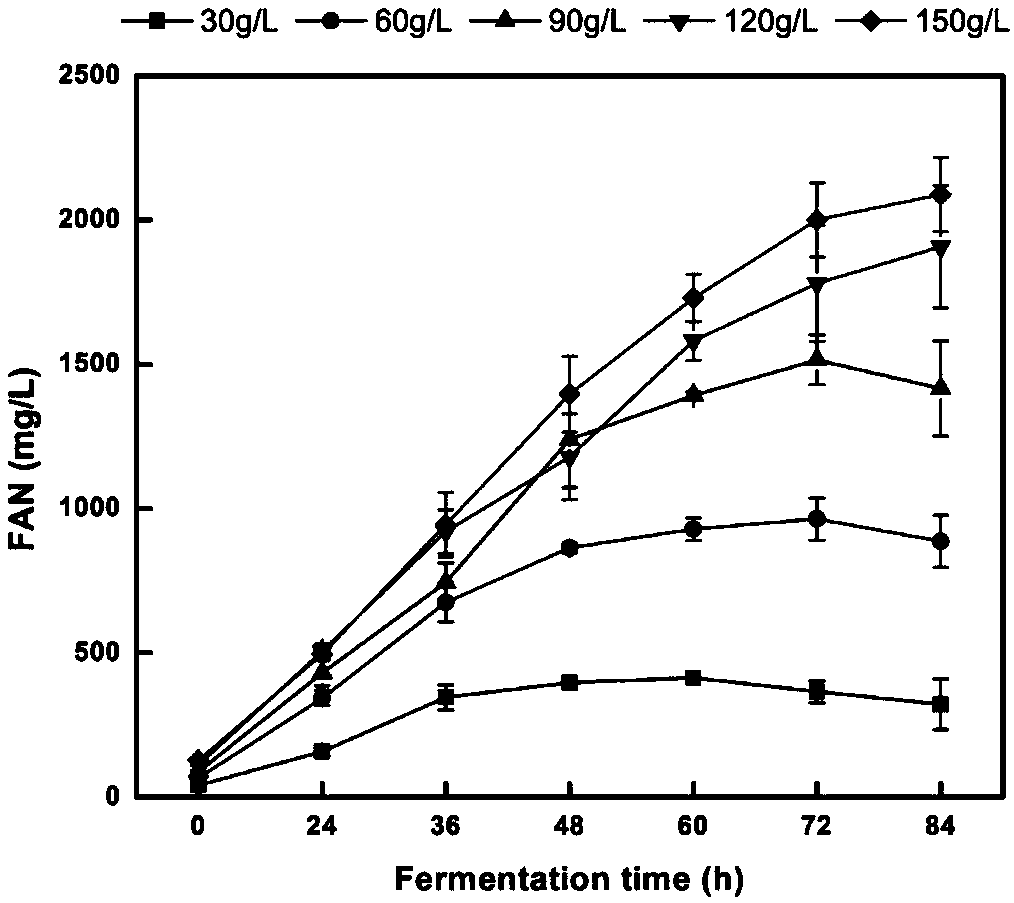

[0027] In this embodiment, rapeseed meal, soybean meal and peanut meal were used for the test respectively; wherein, for each oil seed meal, the concentration in water was within the range of 30-150g / L, and 30, 60, 90, 120, 150g / L were tested; the added concentration of glucose in water was 20g / L. As the concentration of oilseed meal increases, the hydrolysis time will gradually increase, and the addition of carbon source can promote the growth of Bacillus amyloliquefaciens, thereby shortening the fermentat...

Embodiment 2

[0031]A method for stably and efficiently hydrolyzing oilseed meal, the method specifically comprising: mixing oilseed meal, glucose and water in proportion, sterilizing at 121°C for 20 minutes, and adding hydrolyzate to it at a ratio of 5% of the volume of the fermentation broth after cooling. Bacillus amylogenus CX-20 is then stirred and fermented at 28° C. for 72 hours in an air-lift fermenter without feeding or changing fermentation conditions to obtain oilseed meal hydrolyzate.

[0032] In this example, the effect of adding different concentrations of carbon sources on the composition of oilseed meal hydrolyzate was studied. The oilseed meal was tested with rapeseed meal, soybean meal and peanut meal respectively; the concentration of each oilseed meal in water was within the range of 90 g / L; the concentration of glucose in water was 0-100g / L g / L L, choose 0, 20, 40, 60, 80, 100g / L respectively for testing.

[0033] Under the condition of adding different initial concent...

Embodiment 3

[0037] A method for stably and efficiently hydrolyzing rapeseed meal, the method specifically comprising: mixing rapeseed meal, glucose and water in proportion, sterilizing at 121°C for 20 minutes, and adding hydrolyzate to it at a ratio of 5% of the volume of the fermentation broth after cooling. Bacillus amylogenus CX-20 was then stirred and fermented at 28° C. for 72 hours in an air-lift fermenter without feeding or changing fermentation conditions to obtain oilseed meal hydrolyzate. Among them, the initial concentration of rapeseed meal was 90 g / L, and the initial concentration of glucose was 80 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com