System and method capable of realizing cooperation of pulverized coal gasification with iron ore reduction

A technology of iron ore and pulverized coal, which is applied in the system field of pulverized coal gasification and iron ore reduction, can solve the problems of large particle size of raw materials, poor heat and mass transfer effects, and more consumption, so as to improve the utilization rate , The effect of heat transfer and mass transfer in the furnace is good, and the effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

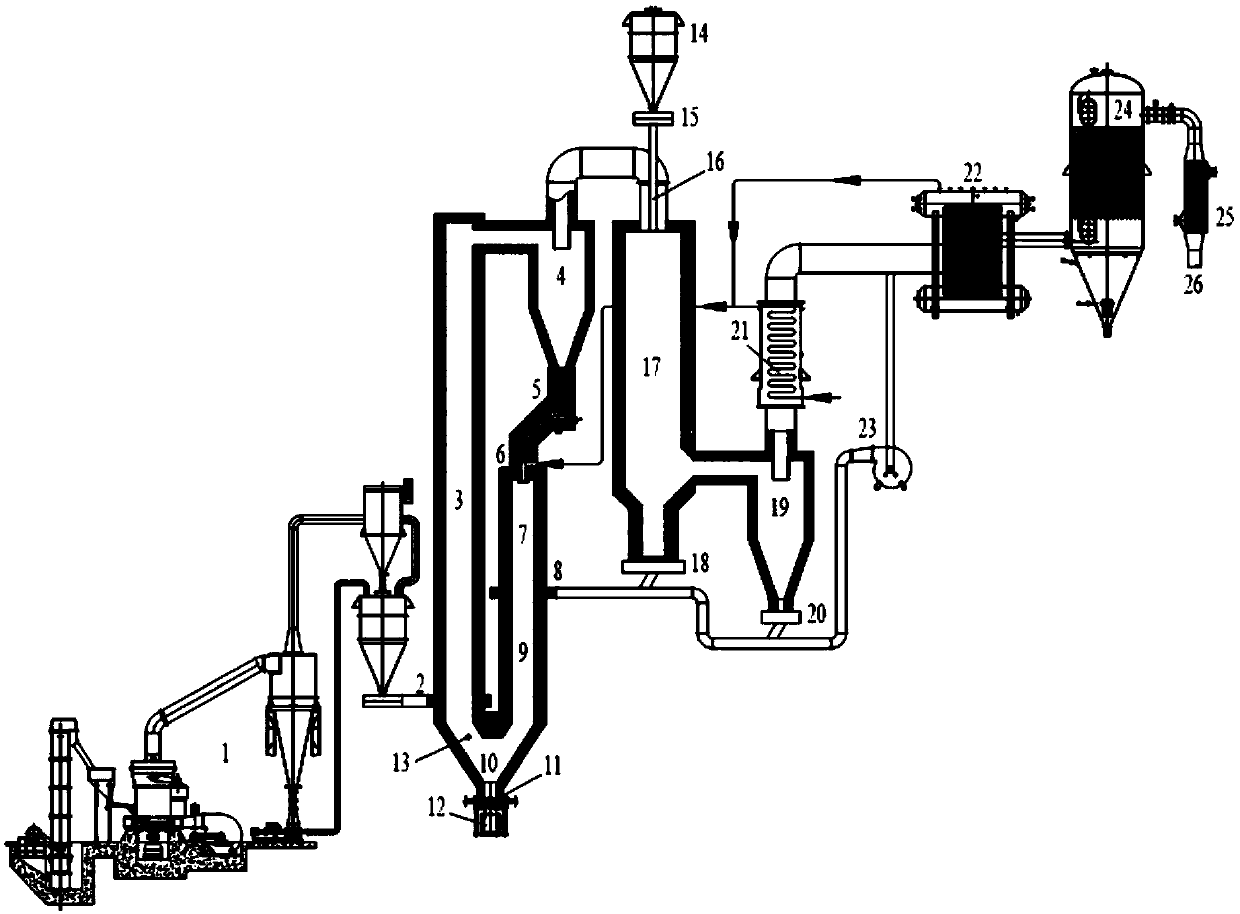

[0054] A system for pulverized coal gasification and iron ore reduction, including a pyrolysis gasification device, a reduction device 17, and a first cyclone separator 4. The pyrolysis gasification device is a U-shaped reaction device connected at the bottom, and one side is a pyrolysis device. Section 3, the upper part on the other side is the gasification section 7, the lower part is the gasification reduction section 9, the reduction device 17 is connected with the pyrolysis gasification device, the raw coal gas produced by the pulverized coal entering the pyrolysis section 3 enters the reduction device 17, and reduces The sponge iron powder produced by device 17 reducing iron ore powder enters the gasification reduction section 9 of the pyrolysis gasification device, the air inlet of the first cyclone separator 4 is connected to the pyrolysis section 3, and the powder coke outlet at the bottom is connected to the gasification section 7. The top is connected, and the coke c...

Embodiment 2

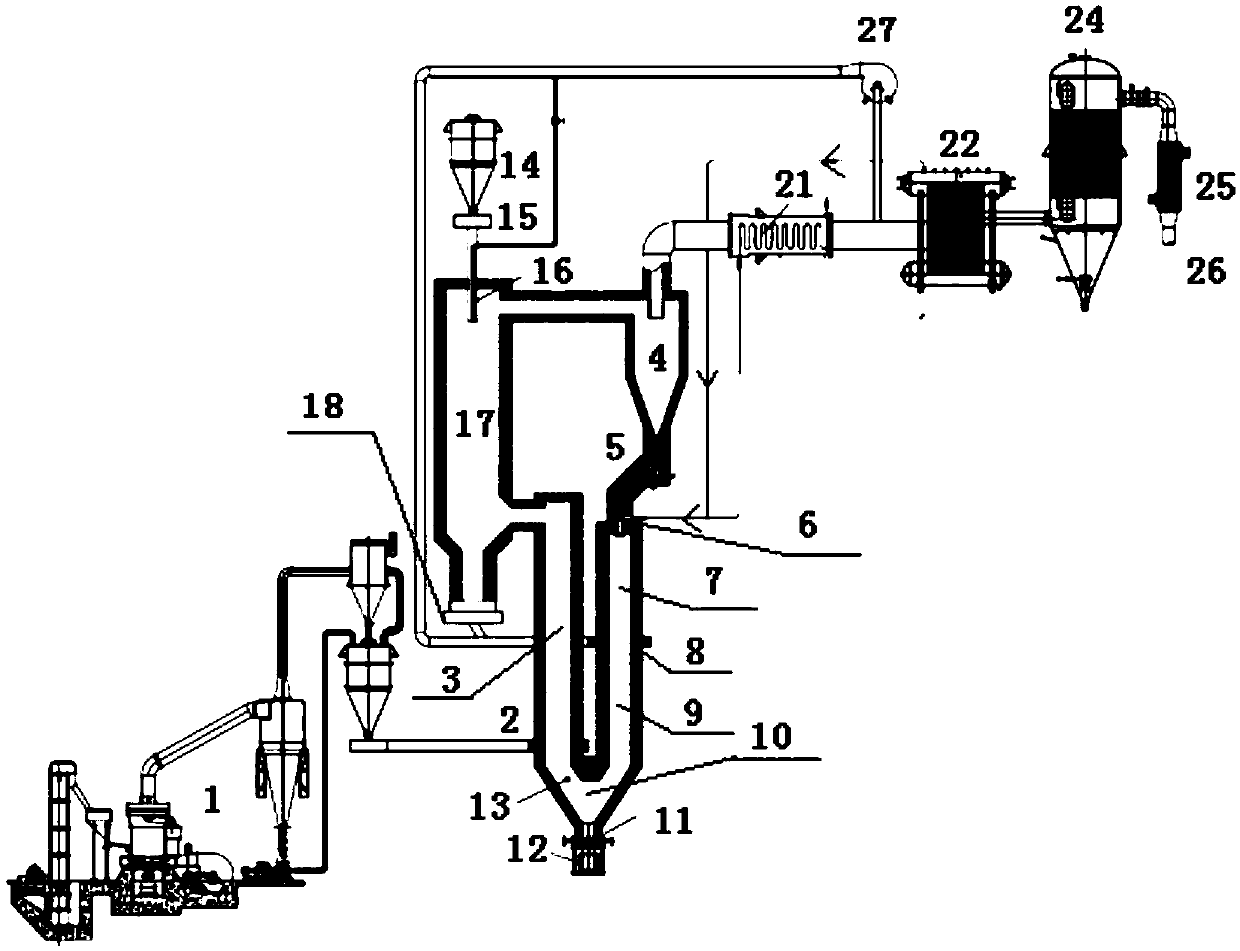

[0066] A system for pulverized coal gasification and iron ore reduction, including a pyrolysis gasification device, a reduction device 17, and a first cyclone separator 4. The pyrolysis gasification device is a U-shaped reaction device connected at the bottom, and one side is a pyrolysis device. Section 3, the upper part of the other side is the gasification section 7, the lower part is the gasification reduction section 9, the reduction device 17 is connected with the pyrolysis gasification device, the raw coal gas produced by the pyrolysis section 3 enters the reduction device 17, and the reduction device 17 produces The sponge iron powder enters the gasification reduction section 9 of the pyrolysis gasification device, the air inlet of the first cyclone separator 4 is connected to the pyrolysis section 3, the powder coke outlet at the bottom is connected to the top of the gasification section 7, and the pyrolysis section 3 The powder coke carried in the raw coal gas is separ...

Embodiment 3

[0077] Coal gasification of the system described in Example 1 and a method for synergistic reduction of iron ore

[0078] 1) After the pulverized coal is ground (coal powder particle size distribution is 20-500 μm), it enters the pyrolysis section 3 of the pyrolysis gasification device, and the high-temperature gas generated on the other side of the pyrolysis gasification device enters the pyrolysis section 3, and the thermal The gas flow velocity in the pyrolysis section is 5m / s, the residence time is 5s, the gas temperature at the bottom pyrolysis section 3 inlet of the pyrolysis section 3 is 1200°C, and the raw gas temperature at the top outlet of the pyrolysis section 3 is 1050°C; Pyrolysis, the raw coal gas produced carries powder coke into the first cyclone separator 4, and the raw coal gas after the powder coke is separated by the first cyclone separator 4 enters the reduction device 17;

[0079] 2) The iron ore powder enters the reduction device 17, where the reduction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com