Method for preparing structural color film layer on surface of zirconium-based metal glass

A zirconium-based metallic glass and structural color technology, which is applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of unfavorable long-term use, relaxation and crystallization of metallic glass, and large residual stress of the colored layer. Achieve the effect of fast color development, smooth surface and improved thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

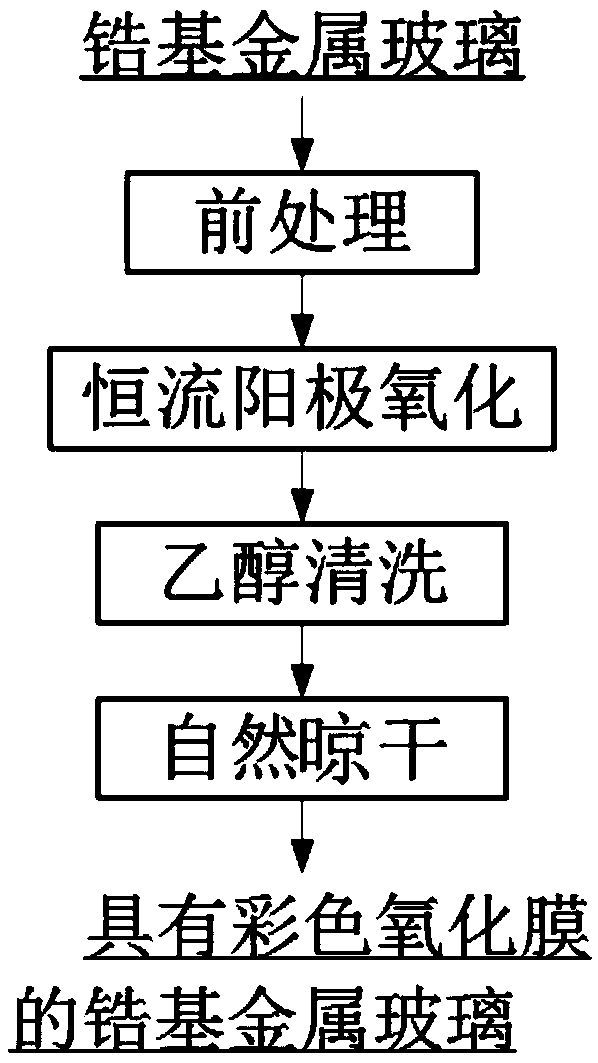

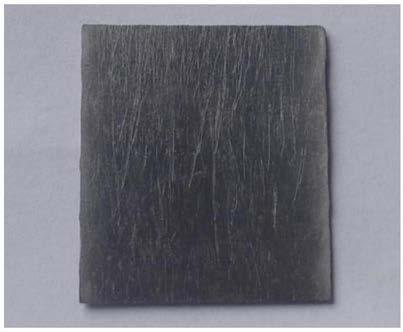

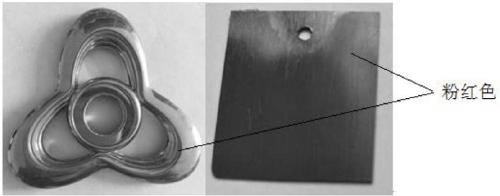

[0037] Such as figure 1 As shown, the pre-treated zirconium-based metallic glass (such as figure 2 Shown) as the anode, the cathode is a graphite plate, and the area of the cathode is 1.5 times the area of the anode, the anode and cathode are placed in the electrolyte, wherein the electrolyte is prepared by dissolving concentrated sulfuric acid in water, and the concentration of the sulfuric acid solution is 80g / L, at a temperature of 25°C and a current density of 30mA / cm 2 , anodized for 9 minutes, then take out the zirconium-based amorphous alloy, wash it with ethanol, and dry it naturally to synthesize a pink oxide film on the surface of the zirconium-based metallic glass (such as image 3 shown), and the prepared pink oxide film has a compact structure, smooth surface, and uniform color. In addition, by such as Figure 4 The Tafel polarization curve obtained from the corrosion resistance test of the zirconium-based metallic glass before and after the preparation of...

Embodiment 2

[0039] Such as figure 1As shown, the zirconium-based metallic glass sheet after pretreatment is used as the anode, and the cathode is a platinum sheet, and the area of the cathode is equal to that of the anode. The cathode and anode are placed in the electrolyte, which is prepared by dissolving concentrated sulfuric acid in water. The concentration of sulfuric acid solution is 90g / L, at a temperature of 20°C and a current density of 40mA / cm 2 , Anodize for 7 minutes, take out the zirconium-based amorphous alloy and wash it with ethanol, and after natural drying, a pink oxide film can be synthesized on the surface of the zirconium-based metallic glass, and the prepared pink oxide film has a dense structure, smooth surface, and uniform color. The corrosion resistance of zirconium-based metallic glass in 3% NaCl solution is improved after anodic oxidation film formation.

Embodiment 3

[0041] Such as figure 1 As shown, the pre-treated zirconium-based metal glass sheet is used as the anode, the cathode is a graphite plate, and the area of the cathode is 1.5 times that of the anode. The cathode and anode are placed in the electrolyte, and the electrolyte is prepared by dissolving concentrated sulfuric acid in water. , where the concentration of concentrated sulfuric acid solution is 90g / L, at a temperature of 18°C and a current density of 40mA / cm 2 , Anodize for 8 minutes, take out the zirconium-based amorphous alloy and wash it with ethanol, and after natural drying, a pink oxide film can be synthesized on the surface of the zirconium-based metallic glass, and the prepared pink oxide film has a dense structure, smooth surface, and uniform color. The corrosion resistance of zirconium-based metallic glass in 3% NaCl solution is improved after anodic oxidation film formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com