Interface modification method of organic metal halide perovskite solar cell

A halide perovskite and solar cell technology, applied in the field of solar cells, can solve problems such as poor stability and low photoelectric conversion efficiency of devices, and achieve strong hydrophobicity and chemical stability, improved stability, and high cell efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First, 0.25 mg of 2,9,16,23-tetra-tert-butyl-29H,31H-phthalocyanine (AR, commercially available) was weighed and added to 1 ml of anisole, and stirred for 8 h until it was completely dissolved. Next, 85 μl of anisole in which phthalocyanine was dissolved was added dropwise in Step 5 of Comparative Example 1.

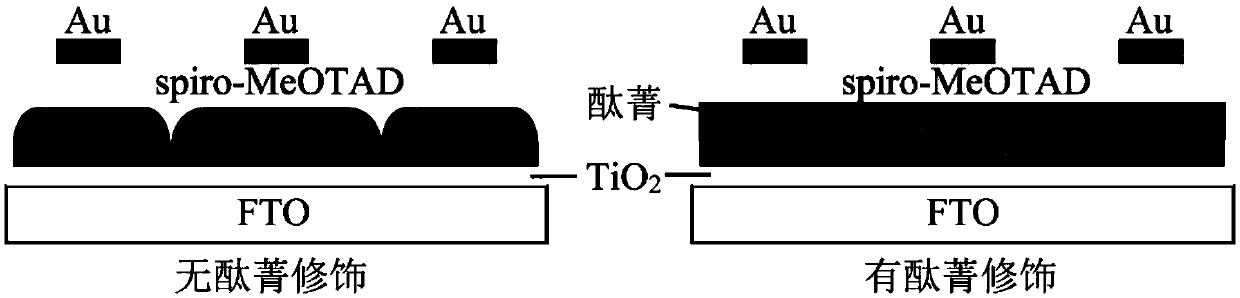

[0041] The FTO / TiO that embodiment 1 step 6 prepares 2 / Perovskite film was characterized by SEM, and the surface SEM image is as follows image 3 shown. image 3 It shows that the perovskite film is still composed of perovskite grains, but the gaps between the grains are mostly covered by phthalocyanine, which can make it difficult for water vapor to invade the perovskite film, thereby improving the stability of the battery. The I-V curve test (under the simulated sunlight of AM 1.5G) was performed on the prepared battery, and the efficiency was 19.8%. Under unpackaged conditions, the battery was stored in an atmospheric environment with a humidity of 50%, an...

Embodiment 2

[0043] First, 0.1 mg of 2,9,16,23-tetra-tert-butyl-29H,31H-phthalocyanine (AR, commercially available) was weighed and added to 1 ml of anisole, and stirred for 8 h until it was completely dissolved. Next, 110 μl of anisole in which phthalocyanine was dissolved was added dropwise in Step 5 of Comparative Example 1.

[0044] The I-V curve (under the simulated sunlight of AM 1.5G) was tested on the prepared battery, and the efficiency was 18.5%. Under the unpackaged condition, the battery was stored in an atmospheric environment with 50% humidity, and the efficiency dropped to more than 70% of the original efficiency (13.0%) after 1 week.

Embodiment 3

[0046] First, weigh 1mg of 1,4,8,11,15,18,22,25-octabutoxy-29H,31H-phthalocyanine (AR, commercially available) and add it to 1ml of anisole, stir for 8h until it is completely dissolve. Next, 100 μl of anisole in which phthalocyanine was dissolved was added dropwise in Step 5 of Comparative Example 1.

[0047] The I-V curve test (under the simulated sunlight of AM 1.5G) was performed on the prepared battery, and the efficiency was 18.2%. Under unpackaged conditions, the battery was stored in an atmospheric environment with 50% humidity, and the efficiency dropped to more than 80% of the original efficiency (14.7%) after 1 week.

[0048] Compared with Comparative Example 2, the initial efficiency of the battery modified by phthalocyanine is also higher, and the efficiency decay is slower, indicating that the interface modification effect of phthalocyanine is better than that of C 60 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com