Reverse osmosis membrane, preparation method and applications thereof

A reverse osmosis membrane, R1-R4 technology, applied in the field of reverse osmosis membrane and its preparation, can solve the problems of illegality and poor chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

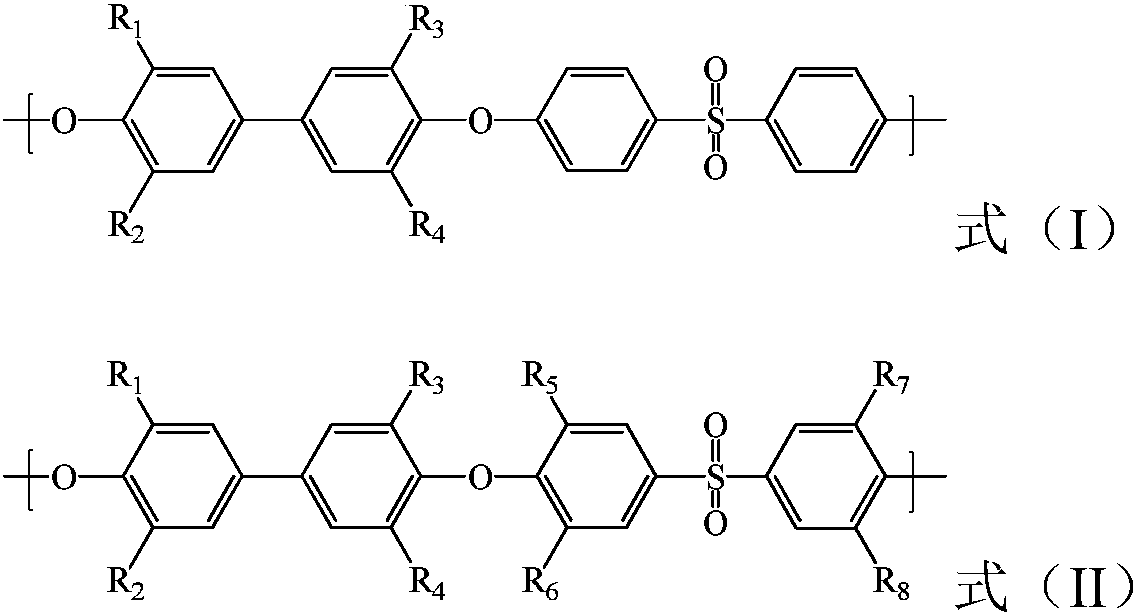

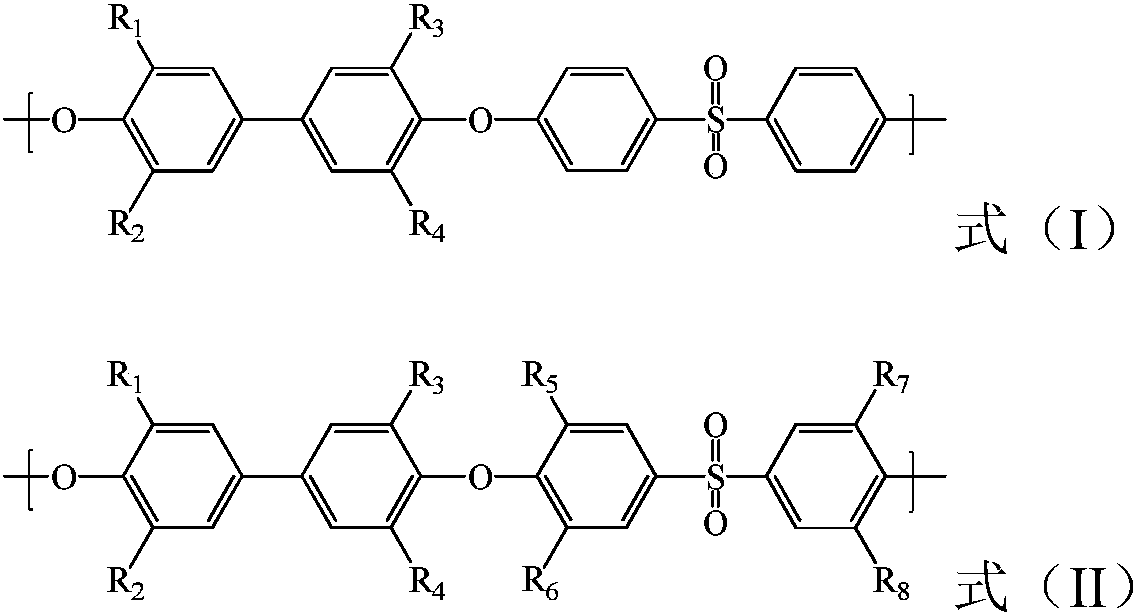

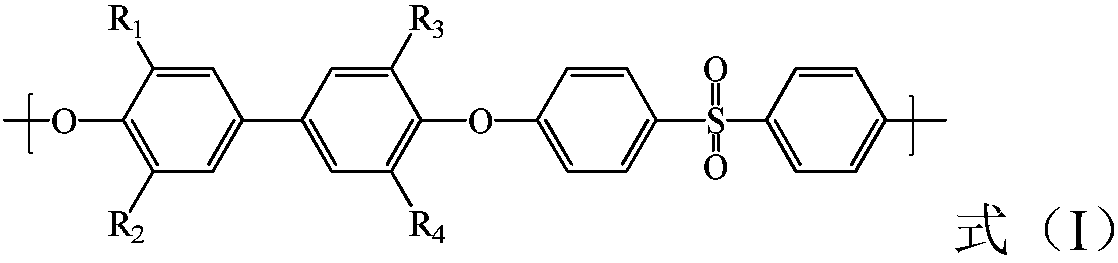

[0030] The present invention also provides a method for preparing a reverse osmosis membrane, the method comprising: in the presence of a photoinitiator, crossing sulfonated polyethersulfone having a structure shown in formula (I) and a structure shown in formula (II) Combined to form a separation layer;

[0031]

[0032] Among them, R 1 -R 4 Each is independently H or C1-C4 alkyl, and R 1 -R 4 Not H at the same time; R 5 -R 8 Each independently is H or -SO 3 M, and R 5 -R 8 Not H at the same time, M is an alkali metal.

[0033] In the present invention, the above-mentioned sulfonated polyethersulfone is not particularly limited, and various sulfonated polyethersulfones used in the separation layer of reverse osmosis membranes in the field can be used.

[0034] According to a preferred embodiment of the present invention, R 1 -R 4 each independently is H or methyl, and R 1 -R 4 not simultaneously H; preferably, R 1 -R 4 Both are methyl.

[0035] According to a...

Embodiment 1

[0067] 1.0 g of dried sulfonated polyarylethersulfone (ion exchange capacity: 1.98 mmol / g) and 0.2 g of benzophenone were dissolved in a mixed solvent composed of 100 g of formic acid, ethylene glycol monomethyl ether and deionized water. The bisphenol A polysulfone support layer was fixed on a glass plate, and the prepared coating solution was evenly brushed on the surface of the support layer, and then heat-treated at 70°C for 10 minutes to obtain an initial composite reverse osmosis membrane. Then put the initial membrane into a UV box with a wavelength of 254nm for 5 minutes and take it out to obtain a cross-linked sulfonated polyarylethersulfone composite reverse osmosis membrane (N1) with a separation layer thickness of 185nm.

Embodiment 2

[0069] 0.75 g of dried sulfonated polyarylethersulfone (ion exchange capacity: 1.16 mmol / g) and 0.0075 g of benzophenone were dissolved in a mixed solvent composed of 100 g of formic acid, ethylene glycol monomethyl ether and deionized water. The bisphenol A polysulfone support layer was fixed on a glass plate, and the prepared dilute coating solution was evenly brushed on the surface of the support layer, and then heat-treated at 50°C for 15 minutes to obtain an initial composite reverse osmosis membrane. Then put the initial membrane into a UV box with a wavelength of 254nm for 5 minutes and take it out to obtain a cross-linked sulfonated polyarylethersulfone composite reverse osmosis membrane (N2) with a separation layer thickness of 155nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com