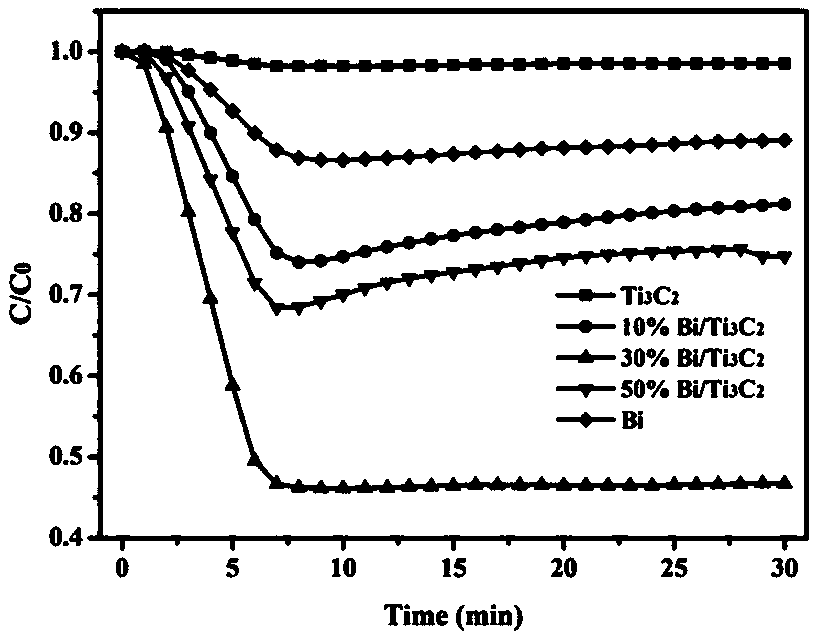

Bi/Ti3C2 nanosheet photocatalyst for catalytic reduction of NOx, and preparation method thereof

A photocatalyst and nanosheet technology, applied in the field of photocatalysis, can solve the problems of low removal rate and unstable photocatalytic performance, and achieve the effect of reducing NOx content, long service life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment prepares catalytic reduction NO x Bi / Ti 3 C 2 The method of nanosheet photocatalyst is mainly realized by the following steps:

[0032] (1) 30ml, 50% volume concentration of hydrofluoric acid solution is added to place 3.0g Ti 3 AlC 2 Powder (hydrofluoric acid and Ti 3 AlC 2 The mass ratio of the powder is 5:1) in the polytetrafluoroethylene liner of the hydrothermal kettle, magnetically stirred at 40 °C for 48 hours in the hydrothermal kettle, and the powder after the reaction was extracted by centrifugation, and the upper layer of powder was taken and washed with deionized water until neutral, then washed twice with ethanol, and dried at 80°C for 12 hours to obtain an intermediate product;

[0033] (2) Add the intermediate product into dimethyl sulfoxide solvent, stir magnetically at room temperature for 12 hours; remove the residual liquid by centrifugation, wash three times with deionized water, wash once with absolute ethanol, and dry at 80°C ...

Embodiment 2

[0038] This embodiment prepares catalytic reduction NO x Bi / Ti 3 C 2 The method of nanosheet photocatalyst is mainly realized by the following steps:

[0039] (1) The hydrofluoric acid solution of 60ml, 50% volume concentration is added to put 3.0g Ti 3 AlC 2 Powder (hydrofluoric acid and Ti 3 AlC 2 The mass ratio of the powder is 10:1) in a polytetrafluoroethylene liner of a hydrothermal kettle, magnetically stirred for 40h at a temperature of 50°C in a hydrothermal kettle, and the powder after the reaction is extracted by centrifugation, and the upper layer of powder is taken and washed with deionized water until Neutral, then washed twice with ethanol, dried at 70°C for 15 hours to obtain an intermediate product;

[0040] (2) Add the intermediate product into dimethyl sulfoxide solvent, stir magnetically at room temperature for 10 h; remove the residual liquid by centrifugation, wash three times with deionized water, wash once with absolute ethanol, and dry at 70°C fo...

Embodiment 3

[0043] This embodiment prepares catalytic reduction NO x Bi / Ti 3 C 2 The method of nanosheet photocatalyst is mainly realized by the following steps:

[0044] (1) The hydrofluoric acid solution of 90ml, 50% volume concentration is added to put 3.0g Ti 3 AlC 2 Powder (hydrofluoric acid and Ti 3 AlC 2 The mass ratio of the powder is 15:1) in a polytetrafluoroethylene liner of a hydrothermal kettle, magnetically stirred for 32 hours at a temperature of 60 °C in a hydrothermal kettle, and the powder after the reaction is extracted by centrifugation, and the upper layer powder is taken and washed with deionized water until Neutral, then washed twice with ethanol, dried at 75°C for 10 hours to obtain an intermediate product;

[0045] (2) Add the intermediate product into dimethyl sulfoxide solvent, stir magnetically at room temperature for 15 hours; remove the residual liquid by centrifugation, wash three times with deionized water, wash once with absolute ethanol, and dry at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com