Preparation method of ddr zeolite molecular sieve

A technology of zeolite molecular sieve and synthesis method, which is applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolite, etc. Mass diffusion is hindered, the method is efficient, and the operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

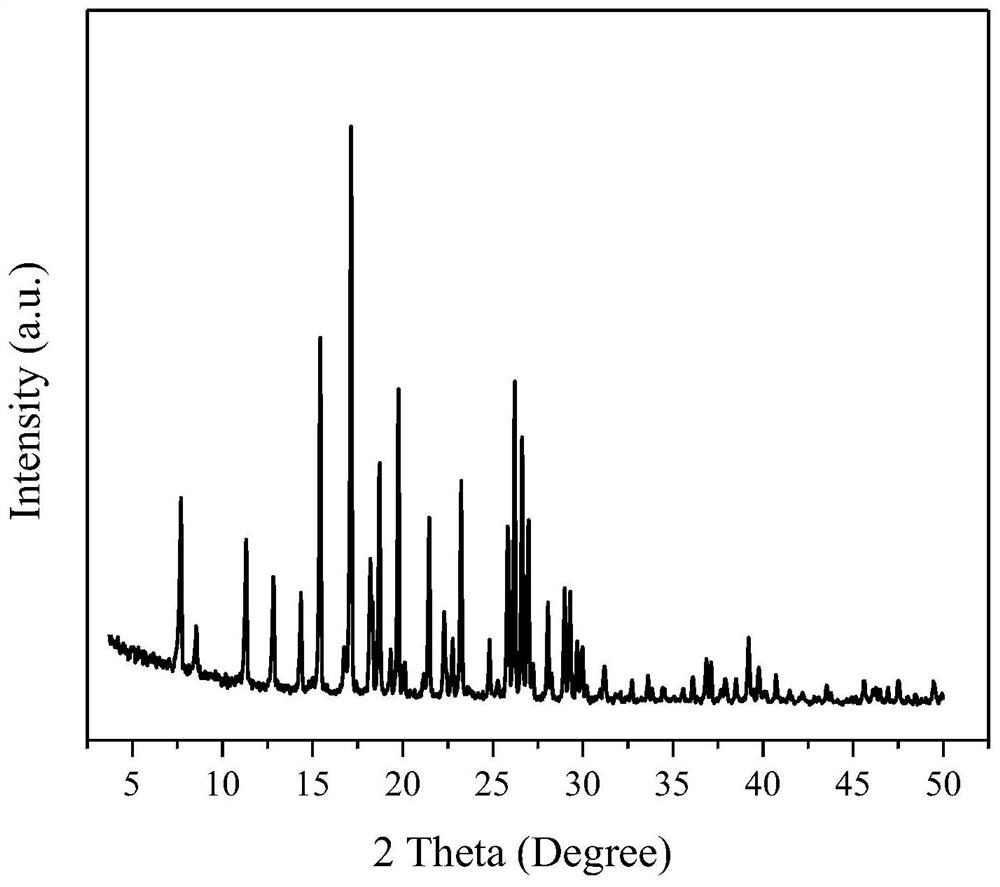

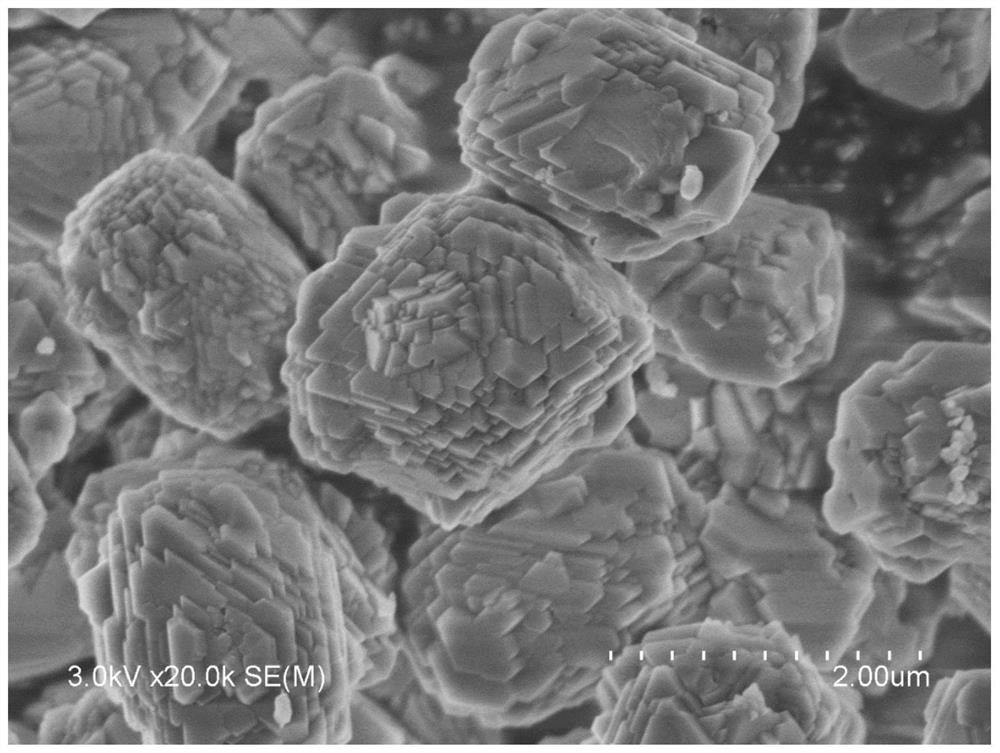

[0022] Dissolve 1.15g of boric acid and 0.45g of sodium hydroxide in 70g of water, add 19.9g of dimethyl diisopropylammonium hydroxide solution (20wt%) and stir evenly, and finally add 16ml of Ludox AS-40 silica sol slowly under stirring, After stirring for 1 h, the above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 160°C for crystallization for 120 hours. After the reaction, the solid was filtered, washed with distilled water, and dried at 100° C. to obtain a solid powder. The raw powder solid is placed in a muffle furnace and roasted at a temperature of 550° C. for 5 hours to obtain the final product. After calcination, the sample shows a stable DDR molecular sieve structure, and the XRD pattern is as follows figure 1 Shown; the primary particle size is 100-300nm, the aggregate size is 2-3μm, the SEM photo is as follows figure 2 shown.

Embodiment 2

[0024] Dissolve 1.15g of boric acid, 0.45g of sodium hydroxide, and 0.3g of aluminum isopropoxide in 70g of water, add 19.9g of dimethyl diisopropylammonium hydroxide solution (20wt%) and stir evenly, and finally slowly add 16ml of Ludox AS-40 silica sol, after stirring for 1 hour, put the above mixture into a crystallization kettle lined with polytetrafluoroethylene, and place it in an oven at 165°C for crystallization for 144 hours. The solid obtained after the reaction is filtered, washed, dried and calcined is DDR molecular sieve.

Embodiment 3

[0026] Dissolve 4g sodium tetraborate, 1.7g potassium hydroxide in 80g water, add 42g dimethyl diisopropyl ammonium hydroxide solution (20wt%) and stir evenly, finally slowly add 59g water glass (SiO 2 27wt%,Na 2 O 8.4 wt%), after stirring for 1 h, the above mixture was charged into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 180° C. for 72 hours for crystallization. The solid obtained after the reaction is filtered, washed, dried and calcined is DDR molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com