Fosfomycin disodium preparation method

A technology of fosfomycin sodium and sodium hydroxide, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the problem of large loss of anhydrous ethanol, non-recyclable application, and spray drying Problems such as huge equipment, to achieve the effect of reducing production costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation process of fosfomycin sodium is as follows:

[0018] a. Sodium hydroxide is dissolved in industrial ethanol, and the temperature is lowered for subsequent use;

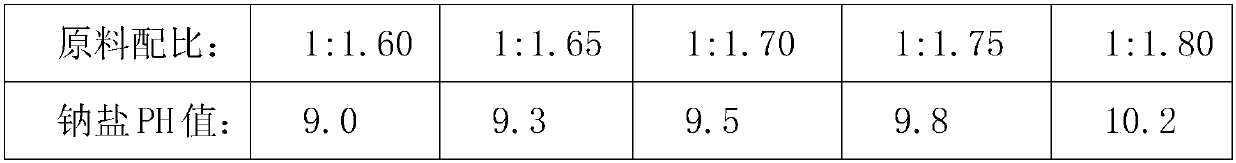

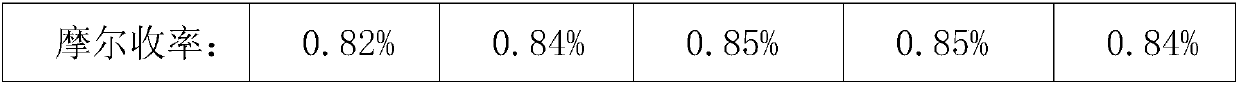

[0019] b. Put the solid left phosphorus and right amine salt and industrial ethanol into the reaction kettle, control the temperature at 30-35°C, add dropwise the sodium hydroxide ethanol solution dissolved in the above step a until the left phosphorus and right amine in the reaction kettle All the salt solids are dissolved, stop dripping, add activated carbon for decolorization, then filter and discard the filter residue to retain the filtrate;

[0020] c. Continue to slowly add sodium hydroxide ethanol solution dropwise to the filtrate obtained in the above step b until the pH value of the solution reaches 10.5, stop the dropwise addition, stir and crystallize after 10h and centrifuge to obtain a large amount of white solid crystals;

[0021] d. Put the white solid crystals obtained in the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com