Far-infrared radiation thermal carbonization equipment

A technology of far-infrared radiation and far-infrared rays, applied in direct heating and dry distillation, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of setting up factories and storing and using large space, air pollution, legal land is hard to find and expensive, etc. problem, to achieve the effect of saving carbonization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

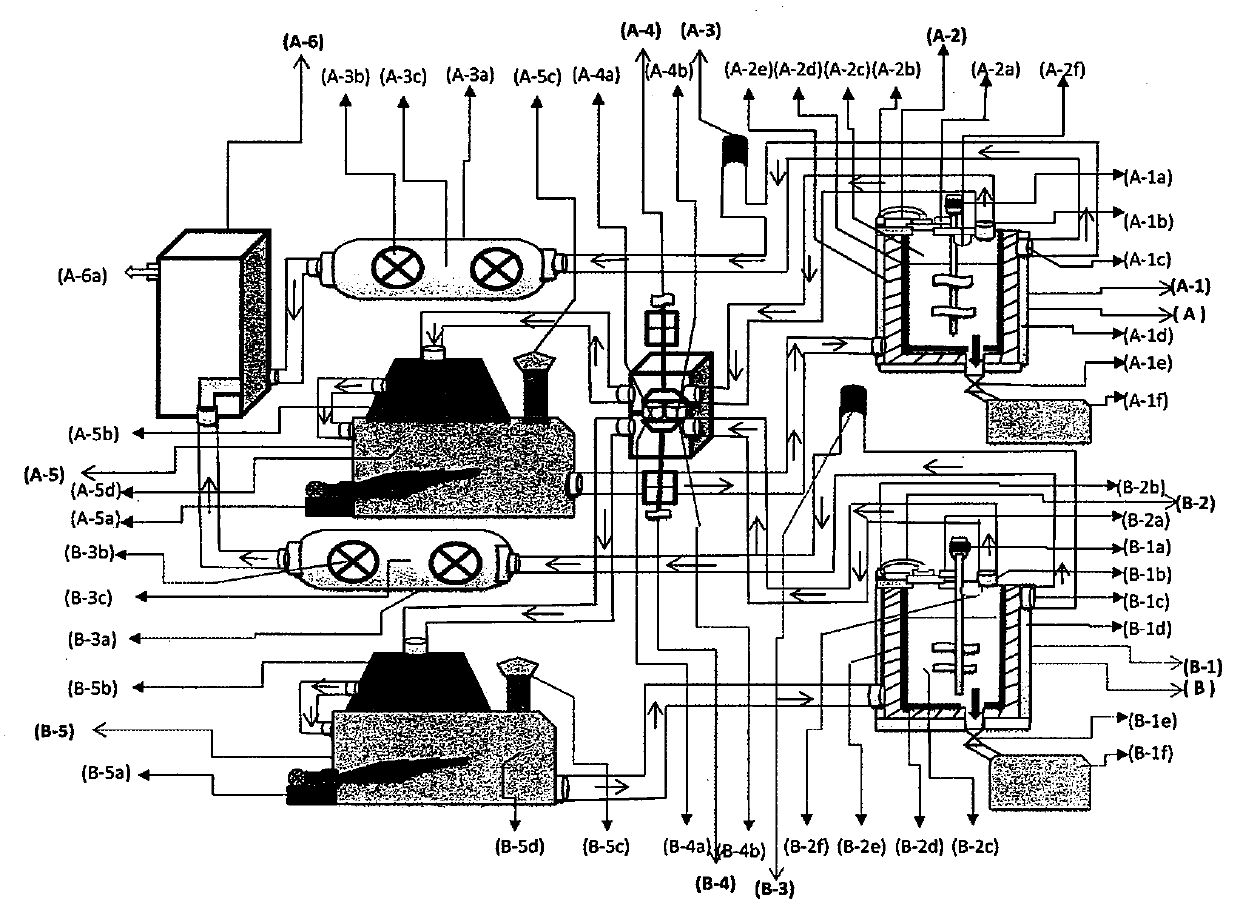

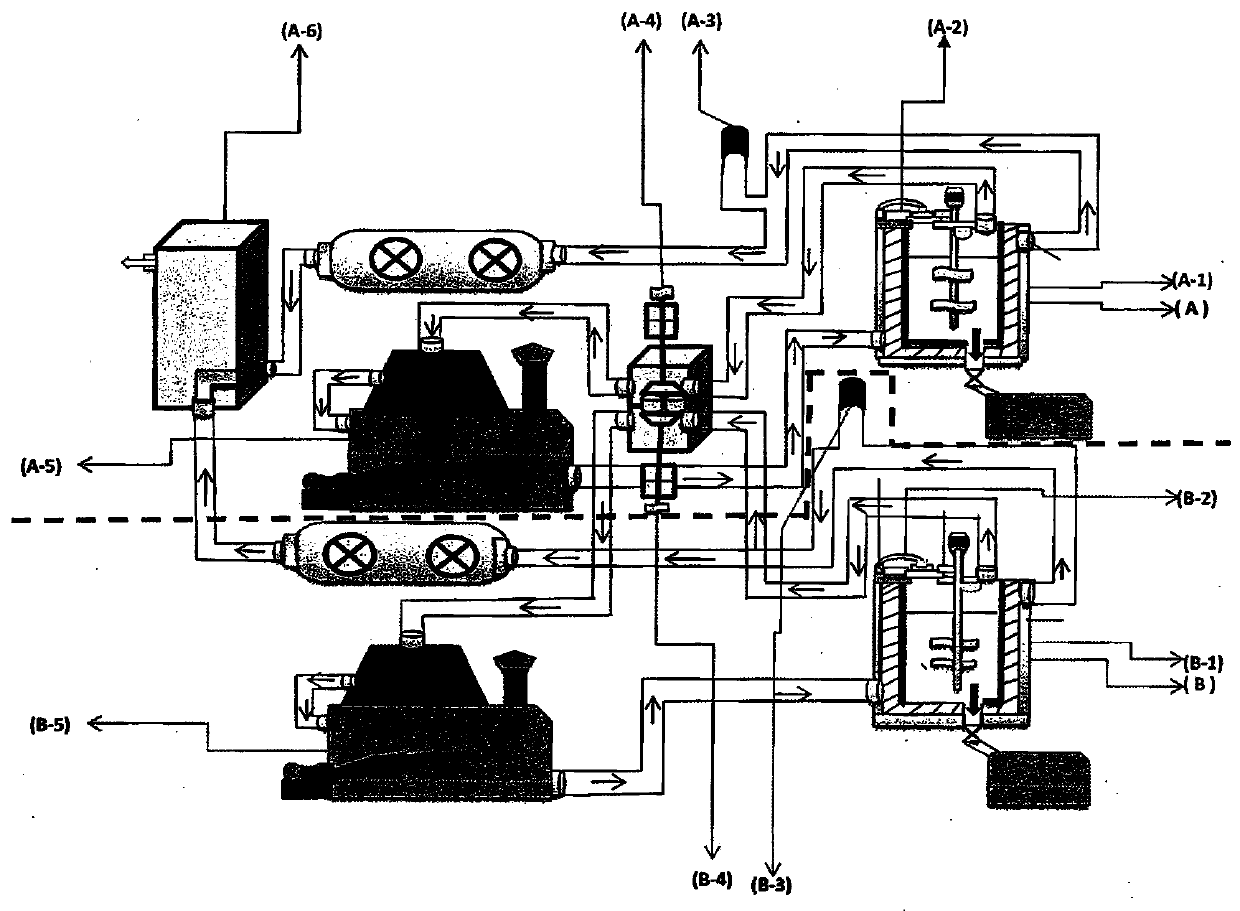

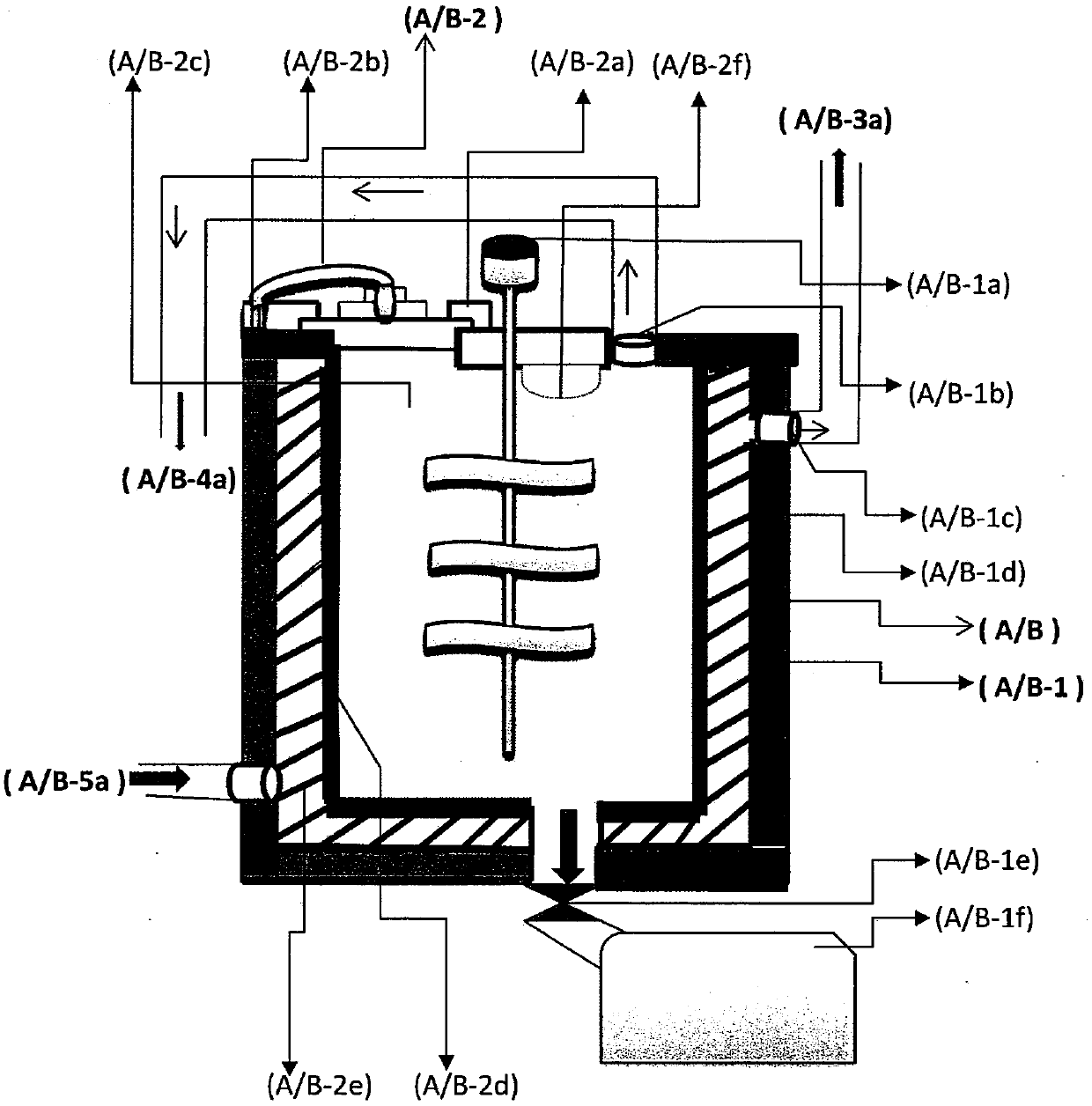

[0128] figure 1 and figure 2 The far-infrared radiant heat carbonization equipment based on two identical individuals A and B of the carbonization device body, the inner and outer walls are made of durable metal materials, and the inner and outer shells are filled with lightweight heat insulating materials, such as magnetized fibers or calcium silicate etc. Form the far-red line ceramic heating layer (A / B-2d) inside the body carbonization container (A / B-1), and use the revolving door to close (A / B-2), and the body sealing cover (A / B-2a ) The hook moves up and down and then enters into the rotating shaft (A / B-2b) by the hydraulic cylinder to form an internal closed space A / B-2c) to place waste. The far-infrared ceramic layer (A / B-2d) is placed inside the above-mentioned body. The present invention uses the far-infrared ceramic layer and burns it through an external combustion device. The auxiliary fuel burner (A / B-5b) can use gas or diesel for combustion The machine assists ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com