Composite battery cell

A battery core and composite technology, applied in the direction of batteries, secondary batteries, battery electrodes, etc., can solve the problems of reducing the performance of the overall battery module, reducing reliability and safety, occupying the volume of the battery module, etc., to achieve heat generation The effect of reducing problems, improving reliability and safety, and simplifying management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In the following detailed description by means of specific embodiments, it will be easier to understand the purpose, technical content, characteristics and effects of the present invention.

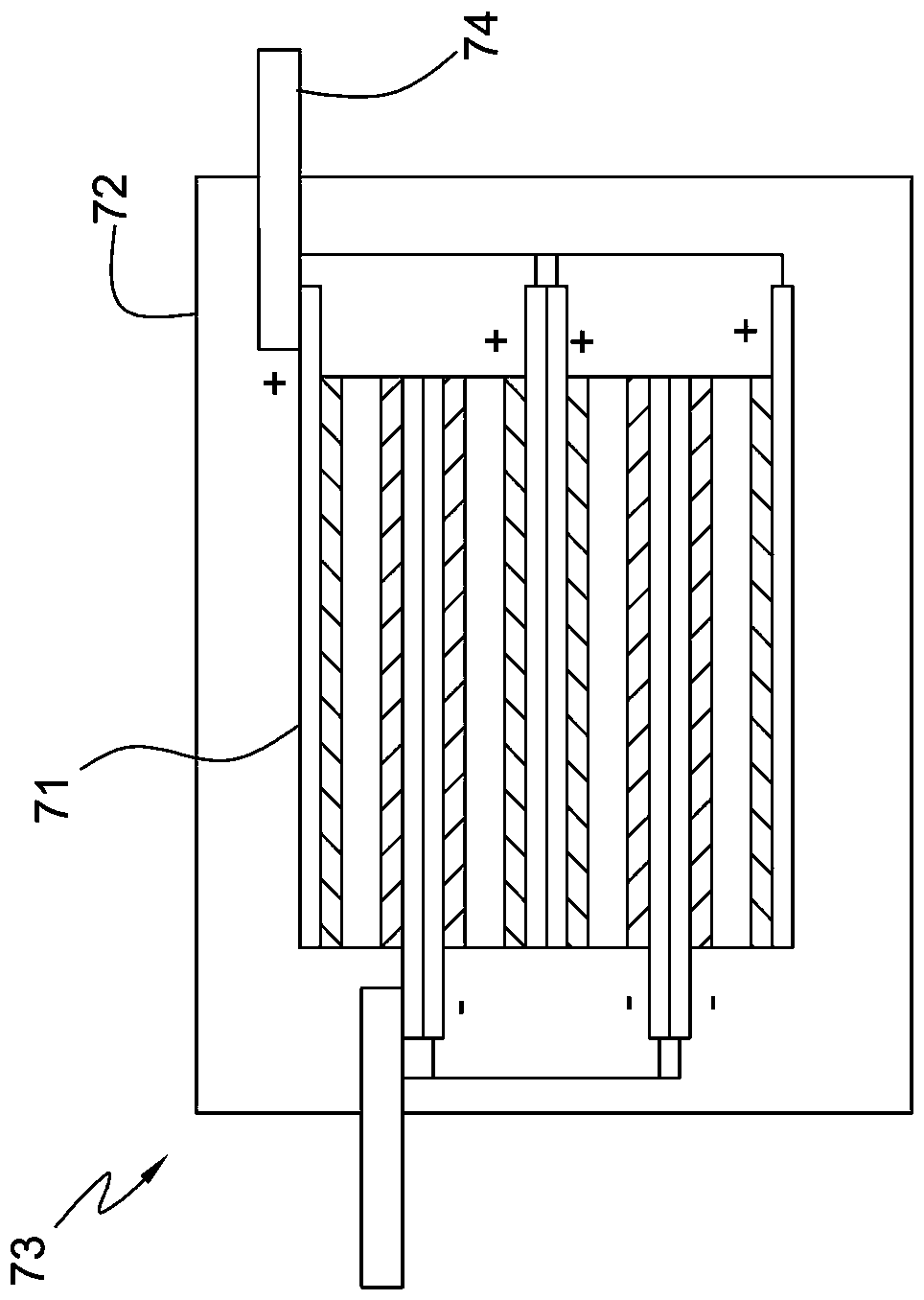

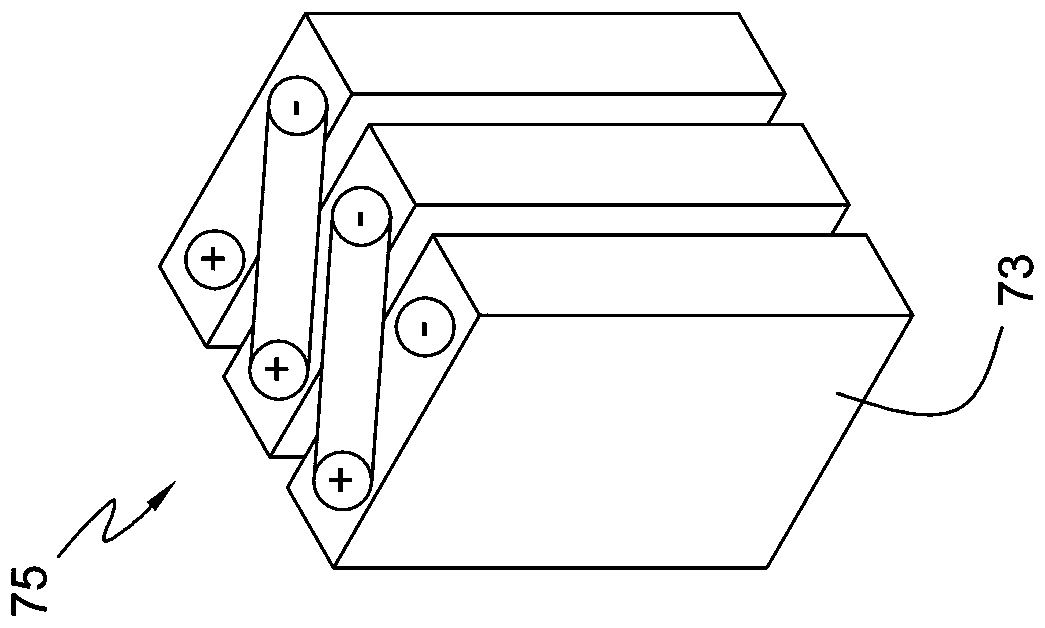

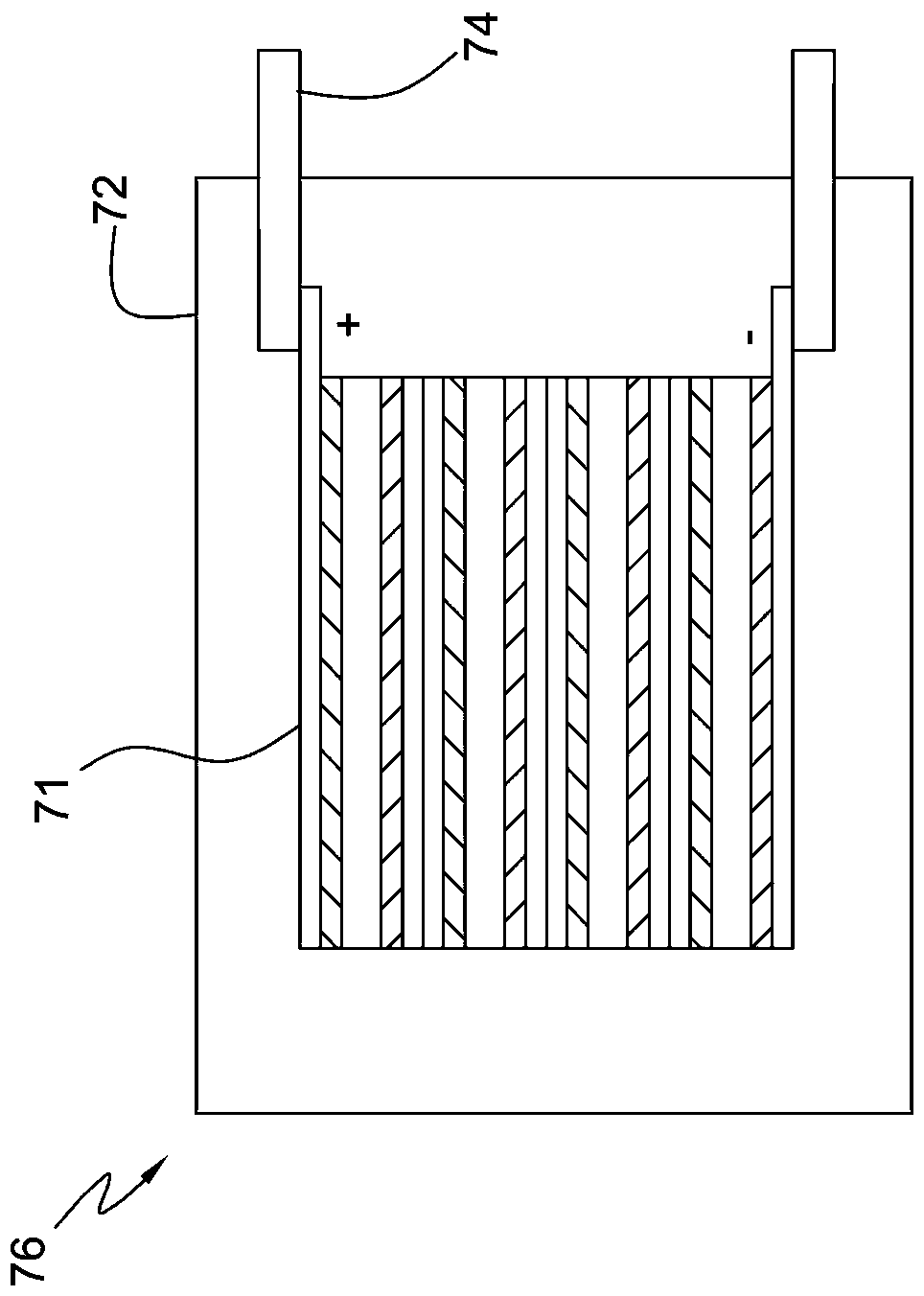

[0061] A composite battery core disclosed in the present invention includes a plurality of power supply unit groups, and the power supply unit group includes a plurality of power supply units connected in series or in parallel, and then connected in parallel or in series with each other. In other words, the battery core can be connected in series and parallel at the same time. Compared with the conventional battery core, only one of the connection methods of series or parallel can be used inside the battery core. , and then there is a very significant difference in the practice of forming the required battery module in parallel or in series externally. Among them, the power supply unit constituting the power supply unit group of the present invention is an independent and complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com