Preparation process of double-protein composite gel with high intensity and high water holding capacity

A composite gel and preparation technology, which is applied in the field of food and meat product material processing, can solve the problems of heavy fishy smell, poor gelation of soybean protein isolate, and deterioration of silver carp surimi gel strength, so as to prevent gelation Effects of degradation, improvement of bioavailability, and ease of absorption by the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

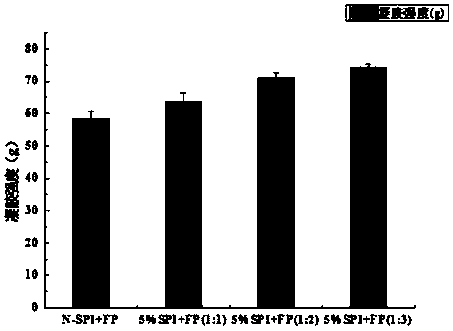

[0015] A high strength and high water holding capacity dual protein composite gel preparation process, comprising the following steps: in step (1), soybean protein isolate is mixed with deionized water (substrate concentration 3%), low degree of restrictive enzymolysis, hydrolysis degree DH 2 =5%; the requirement of adding buffer solution in step (2) is 4 times of volume (V / W) buffer solution (50mM, pH7.5), at 4 ℃, centrifugal 15min under the condition of 8500×g; In step (3) The requirement of adding buffer solution is 4 times of volume (V / W) buffer solution (0.1M NaCl), adopts 6 layers of gauze to filter; In step (4), soybean protein powder and silver carp myofibrillar protein are mixed according to 1:3, The total protein content of all mixed solutions is 60 mg / mL; the two-step heating method in step (5) is heating in a water bath at 40°C for 30 minutes, and heating in a water bath at 90°C for 30 minutes; in step (6), use an ice-water bath to cool to room temperature , store...

Embodiment 2

[0018] A high strength and high water holding capacity dual protein composite gel preparation process, comprising the following steps: in step (1), soybean protein isolate is mixed with deionized water (substrate concentration 3%), low degree of restrictive enzymolysis, hydrolysis degree DH 2 =5%; the requirement of adding buffer solution in step (2) is 4 times of volume (V / W) buffer solution (50mM, pH7.5), at 4 ℃, centrifugal 15min under the condition of 8500×g; In step (3) The requirement of adding buffer solution is 4 times of volume (V / W) buffer solution (0.1M NaCl), adopts 6 layers of gauze to filter; In step (4), soybean protein powder and silver carp myofibrillar protein are mixed according to 1:3, The total protein content of all mixed solutions is 60 mg / mL; the two-step heating method in step (5) is heating in a water bath at 40°C for 30 minutes, and heating in a water bath at 90°C for 30 minutes; in step (6), use an ice-water bath to cool to room temperature , store...

Embodiment 3

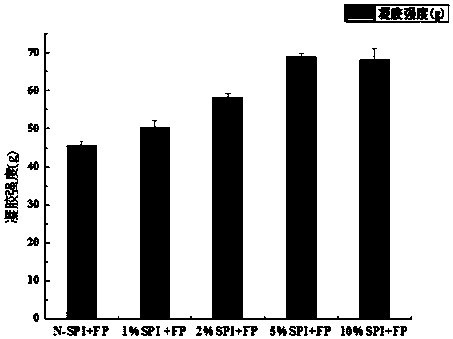

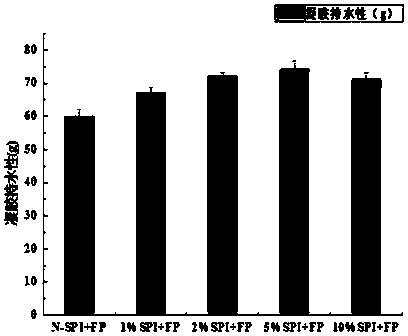

[0021] A preparation process for a high-strength and high-water-holding double-protein composite gel, comprising the following steps: Measuring the performance of the double-protein composite gel in Examples 1 to 2, the specific steps are as follows: (1) Gel strength measurement: at room temperature (20± 1° C.) The gel product is made into a cube gel block with a thickness of 30 mm, which is measured by a TA-XT plus texture analyzer. Select P / 0.5 (diameter: 12mm) for the probe model, and the penetration force obtained by pressing down is the gel strength of the protein. The measurement parameters of the selected physical instrument are as follows: speed before test: 2.0mm / s; test speed: 0.5mm / s; trigger force: 5g; speed after test: 2.0mm / s; puncture distance: 5.0mm. Three parallel experiments were carried out for each sample, and the average value was obtained. (2) Determination of gel water holding capacity: 10 g of protein gel was placed in a 50 mL centrifuge tube and centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com