A kind of preparation method of anti-attenuation gasket

An anti-attenuation and gasket technology, which is applied in the field of anti-attenuation gasket preparation, can solve the problems of general sealing performance improvement of composite boards, etc., and achieve the effects of outstanding creep relaxation resistance, good resilience, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

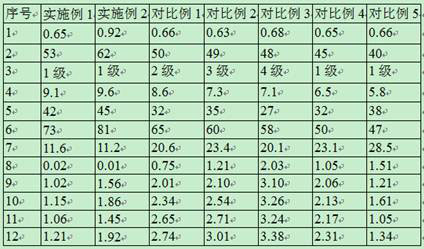

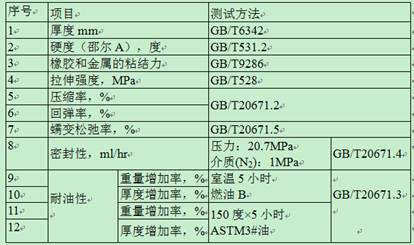

Examples

Embodiment 1

[0027] A preparation method of an anti-attenuation gasket, the anti-attenuation gasket comprises a spring steel strip and a foamed rubber layer, and the foamed rubber layer is arranged on one side of the spring steel strip, comprising the following steps:

[0028] Step S1: Carry out surface treatment to the spring steel strip, in order:

[0029] Cutting: Cut the spring steel strip to the required specifications;

[0030] Degreasing: Use degreasing agent to degrease the surface of the spring steel strip, and the degreasing temperature is: 50°C;

[0031] Water washing: wash the spring steel strip in running water;

[0032] Phosphating: use phosphating solution to phosphate the spring steel strip at a temperature of 23°C;

[0033] One-time drying: The spring steel strip is dried once, and the temperature of the first-time drying is 80°C;

[0034] Glue application: apply adhesive evenly on the surface of the spring steel strip;

[0035] Secondary drying: The spring steel belt ...

Embodiment 2

[0049] A preparation method of an anti-attenuation gasket, the anti-attenuation gasket comprises a spring steel strip and a foamed rubber layer, and the foamed rubber layer is arranged on both sides of the spring steel strip, comprising the following steps:

[0050] Step S1: Carry out surface treatment to the spring steel strip, in order:

[0051] Cutting: Cut the spring steel strip to the required specifications;

[0052] Degreasing: Use degreasing agent to degrease the surface of the spring steel strip, and the degreasing temperature is 55°C;

[0053] Water washing: wash the spring steel strip in running water;

[0054] Phosphating: use phosphating solution to phosphate the spring steel strip, and the treatment temperature is 25°C;

[0055] One-time drying: The spring steel strip is dried once, and the temperature of the first-time drying is 90°C;

[0056] Glue application: apply adhesive evenly on the surface of the spring steel strip;

[0057] Secondary drying: Seconda...

Embodiment 3

[0064] A preparation method of an anti-attenuation gasket, the anti-attenuation gasket comprises a spring steel strip and a foamed rubber layer, and the foamed rubber layer is arranged on both sides of the spring steel strip, comprising the following steps:

[0065] Step S1: Carry out surface treatment to the spring steel strip, in order:

[0066] Cutting: Cut the spring steel strip to the required specifications;

[0067] Degreasing: use degreasing agent to degrease the surface of the spring steel strip, the degreasing temperature is: 52 ℃;

[0068] Water washing: wash the spring steel strip in running water;

[0069] Phosphating: use phosphating solution to phosphate the spring steel strip at a temperature of 15°C;

[0070] One-time drying: The spring steel strip is dried once, and the temperature of the first-time drying is 105°C;

[0071] Glue application: apply adhesive evenly on the surface of the spring steel strip;

[0072] Secondary drying: Secondary drying of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com