Insulating paper for transformer

A technology of insulating paper and transformers, applied in the direction of transformers/inductor coils/windings/connections, chemical instruments and methods, layered products, etc., can solve the problems of poor physical, chemical, electrical performance and environmental adaptability, and achieve excellent physical Chemical properties, good electrical insulation properties, and the effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

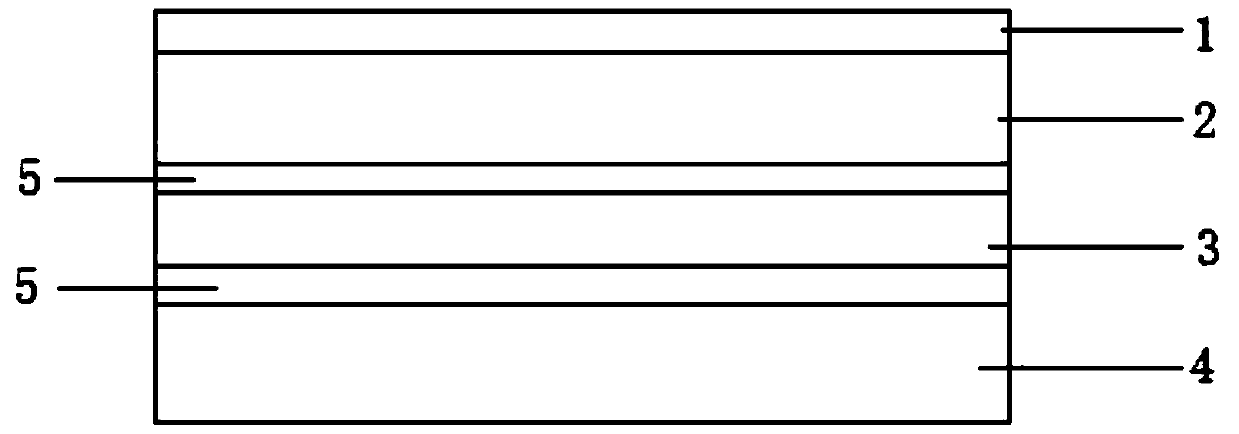

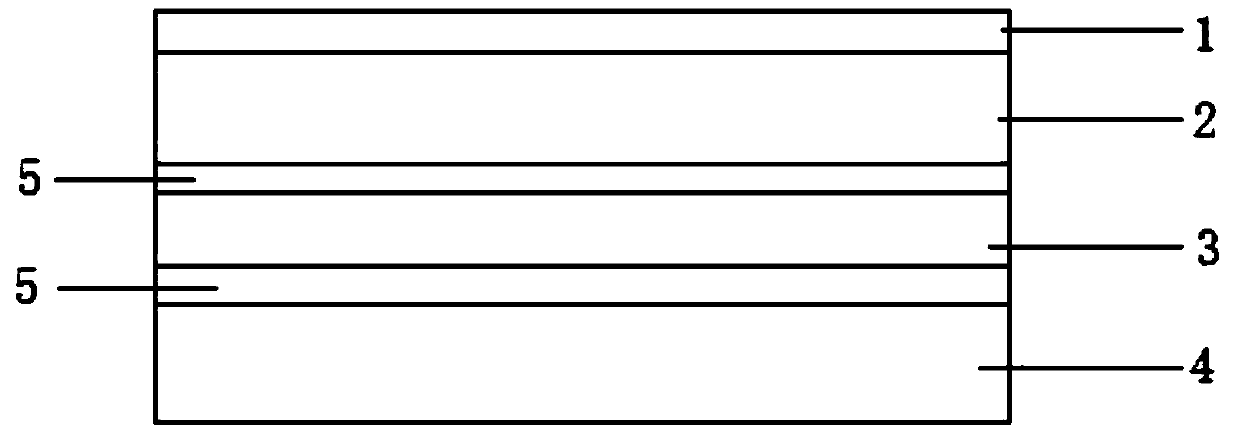

[0027] Please see figure 1 , is a structural schematic diagram of a preferred embodiment of an insulating paper for a transformer according to the present invention. An insulating paper for a transformer includes a surface layer film 1, a first layer of insulating paper 2, an intermediate layer film 3 and The second layer of insulating paper4.

[0028] In this embodiment, the surface film 1 includes epoxy resin, rosin resin, polytetrafluoroethylene, polyvinyl butyral, asbestos and curing agent.

[0029] Further, in this embodiment, the parts by weight of the components of the surface layer film 1 are: 100 parts of epoxy resin, 50-70 parts of rosin resin, 36-50 parts of polytetrafluoroethylene, polyvinyl alcohol Butyraldehyde 16-20 parts, asbestos 16-24 parts, curing agent 20-30 parts.

[0030] Further, in this embodiment, due to the high viscosity and high oxidation resistance of rosin resin, the bonding strength between the surface layer film and the first layer of insulati...

Embodiment 2

[0042] The preparation method of the insulating paper used for the transformer is:

[0043]S1 dilutes the epoxy adhesive with a solvent;

[0044] S2 coating the diluted epoxy adhesive on the surface of the intermediate layer film 3;

[0045] S3 laminating the first layer of insulating paper 2 and the second layer of insulating paper 4 with the middle layer film 3 coated with the epoxy adhesive, and heating to remove the solvent;

[0046] S4 After fully diluting and mixing the components of the surface layer film 1 with a solvent and a dispersant, coating on the surface of the first layer of insulating paper 2 and heating and curing to form the surface layer film 1 .

[0047] In this embodiment, the solvent described in steps S1 and S3 is ethylene glycol ether.

[0048] In this embodiment, the parts by weight of the components of the surface film 1 in step S4 are: 100 parts of epoxy resin, 50-70 parts of rosin resin, 36-50 parts of polytetrafluoroethylene, polyvinyl alcohol ...

Embodiment 3

[0052] Please see figure 1 , is a structural schematic diagram of a preferred embodiment of an insulating paper for a transformer according to the present invention. An insulating paper for a transformer includes a surface layer film 1, a first layer of insulating paper 2, an intermediate layer film 3 and The second layer of insulating paper4.

[0053] In this embodiment, the surface film 1 includes epoxy resin, rosin resin, polytetrafluoroethylene, polyvinyl butyral, asbestos and curing agent.

[0054] Further, in this embodiment, the parts by weight of the components of the surface layer film 1 are: 100 parts of epoxy resin, 50 parts of rosin resin, 36 parts of polytetrafluoroethylene, 16 parts of polyvinyl butyral , 16 parts of asbestos, 20 parts of curing agent.

[0055] Further, in this embodiment, due to the high viscosity and high oxidation resistance of rosin resin, the bonding strength between the surface layer film and the first layer of insulating paper can be fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com