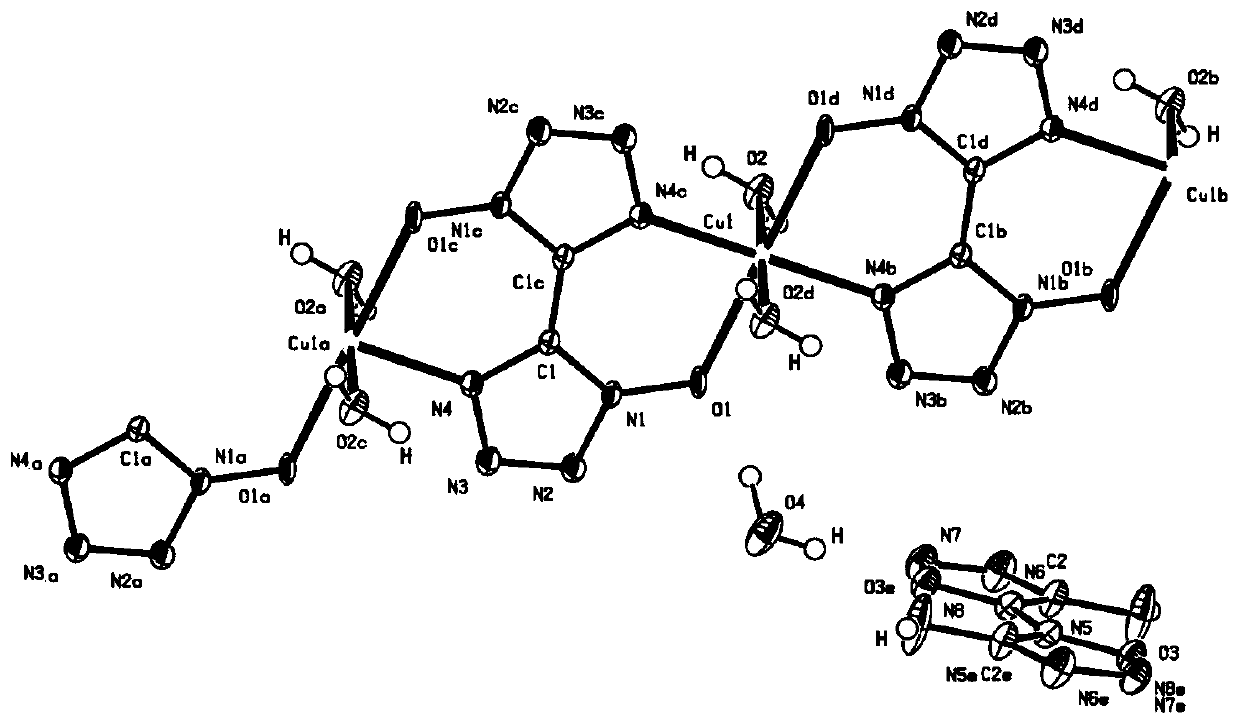

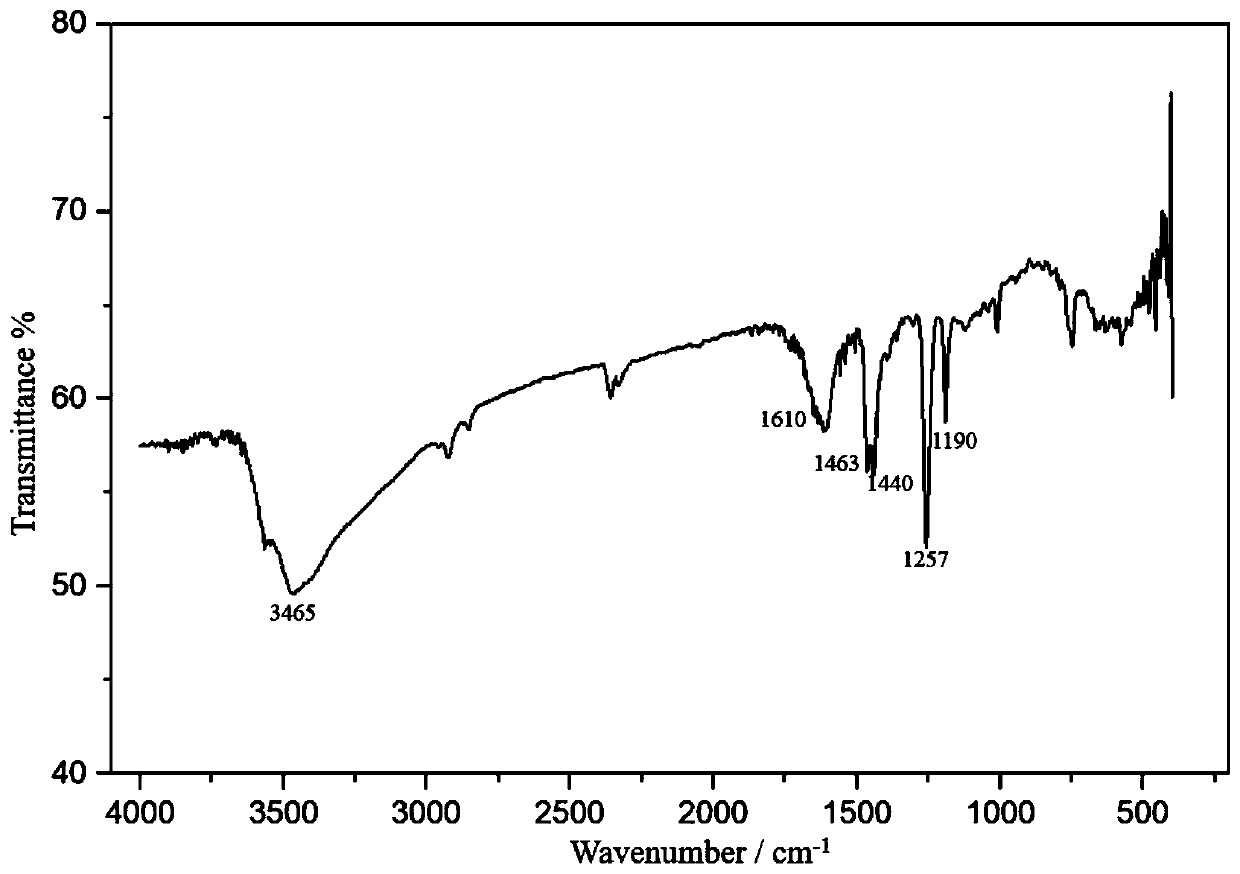

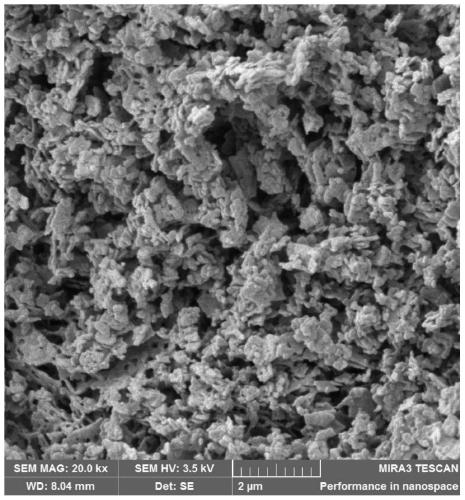

Copper-BTO energetic metal coordination polymer and rapid preparation method thereof

A metal coordination and polymer technology, applied in the field of metal coordination polymer synthesis, can solve problems such as failure to meet the safety requirements of explosives, and achieve the effects of rich structure, extremely short reaction time, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 2.06g (10.0mmol) of 5,5'-bitetrazol-1,1'-dihydroxy dihydrate into a 100mL beaker, then add 50mL of deionized water, and use a magnetic stirrer at a speed of 250 rpm Stir for 5 minutes, then sonicate for 5 minutes. 1.87g (10mmol) of copper nitrate was added to a 50mL beaker, followed by 20mL of deionized water, stirred with a magnetic stirrer at a speed of 250 rpm for 5 minutes, and then ultrasonicated for 5 minutes. The above two solutions were simultaneously poured into a microwave reaction tube and placed in a microwave reactor. The microwave reactor was turned on, and the temperature was raised to 80° C. within two minutes and held for 15 minutes. After the reaction, the microwave reaction tube was taken out, and the solution in the reaction tube was quickly poured into a three-necked flask preheated to 80°C, stirred at a speed of 200 rpm with a magnetic stirrer, and dropped to 50°C / hour. 15°C. After filtering, the filter cake was washed 3 times with deionized...

Embodiment 2

[0025] Add 3.09 g (15.0 mmol) of 5,5'-bitetrazol-1,1'-dihydroxy dihydrate into a 100 mL beaker, then add 60 mL of deionized water, and use a magnetic stirrer at a speed of 250 rpm Stir for 5 minutes. 1.87g (10mmol) of copper nitrate was added to a 50mL beaker, followed by 20mL of deionized water, and the magnetic stirrer was stirred at a speed of 250 rpm for 5 minutes. Mix the above two solutions into the same beaker and sonicate for 5 minutes. The above mixed solution was poured into a microwave reaction tube and placed in a microwave reactor. The microwave reactor was turned on, and the temperature was raised to 90° C. within two minutes and held for 15 minutes. After the reaction, the microwave reaction tube was taken out, and the solution in the reaction tube was quickly poured into a three-necked flask preheated to 90°C, stirred at a speed of 200 rpm with a magnetic stirrer, and dropped to 100°C / hour. 5°C. After filtering, the filter cake was washed 3 times with deion...

Embodiment 3

[0027] Add 2.06g (10mmol) of 5,5'-bitetrazol-1,1'-dihydroxy dihydrate into a 100mL beaker, then add 50mL of deionized water, and stir with a magnetic stirrer at a speed of 250 rpm 5 minutes, followed by 5 minutes of sonication. 3.0 g (16 mmol) of copper nitrate was added to a 50 mL beaker, followed by 25 mL of deionized water, stirred with a magnetic stirrer at a speed of 250 rpm for 5 minutes, and then ultrasonicated for 5 minutes. The above two solutions were simultaneously poured into a microwave reaction tube and placed in a microwave reactor. The microwave reactor was turned on, and the temperature was raised to 80° C. within two minutes and held for 15 minutes. After the reaction, the microwave reaction tube was taken out and placed in a cold water bath to drop to 5° C. at a rate of 200° C. / hour. After filtering, the filter cake was washed 3 times with deionized water at 5°C. After natural drying, 4.31 g of light green copper-BTO energetic metal coordination polymer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com