Ultraviolet-proof fruit and vegetable preservative film, preparation process, and application of preservative film in fruit and vegetable bagging

A fruit and vegetable preservation and UV protection technology, applied in the field of food preservation, can solve the problems of unintended fruit coloring, aggravating fruit injury and deterioration of the environment inside the bag, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

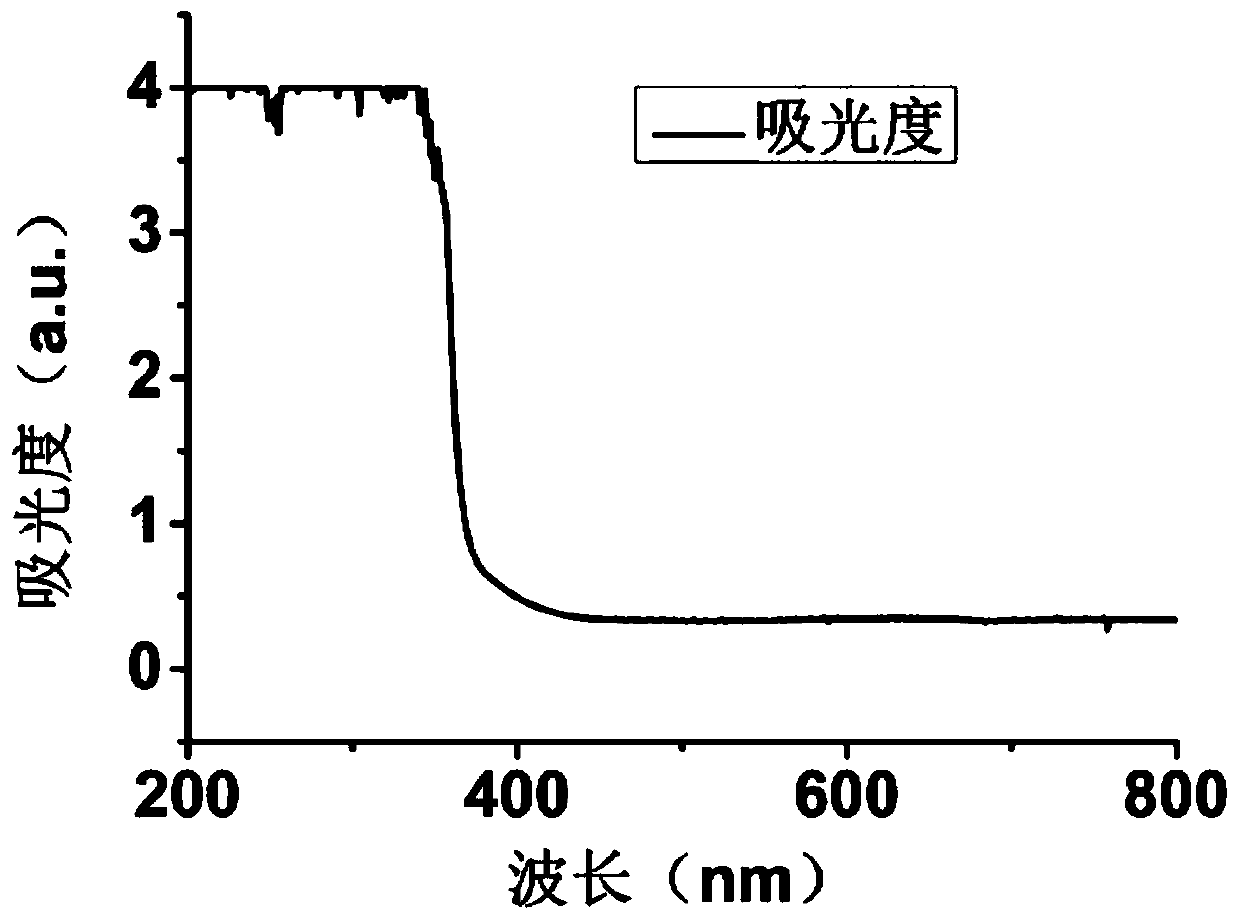

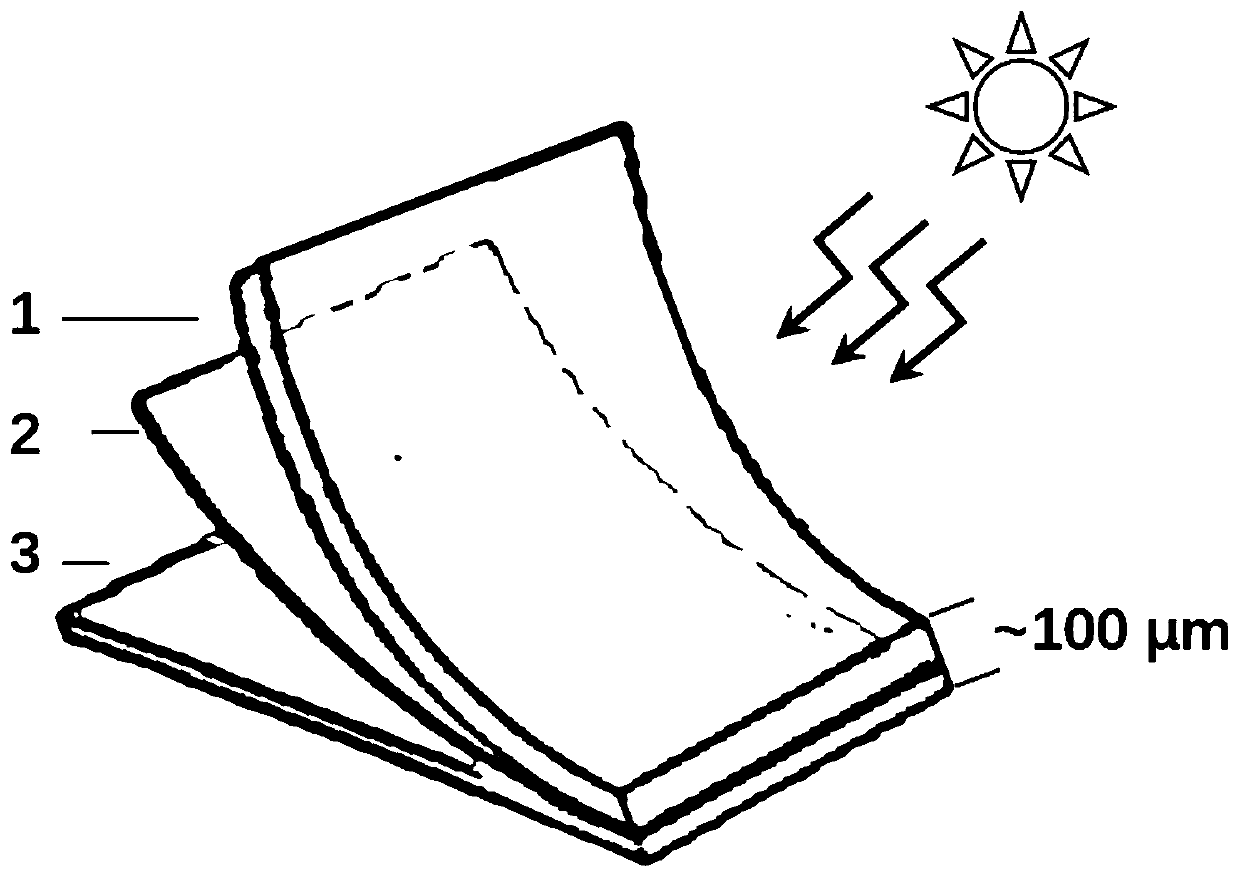

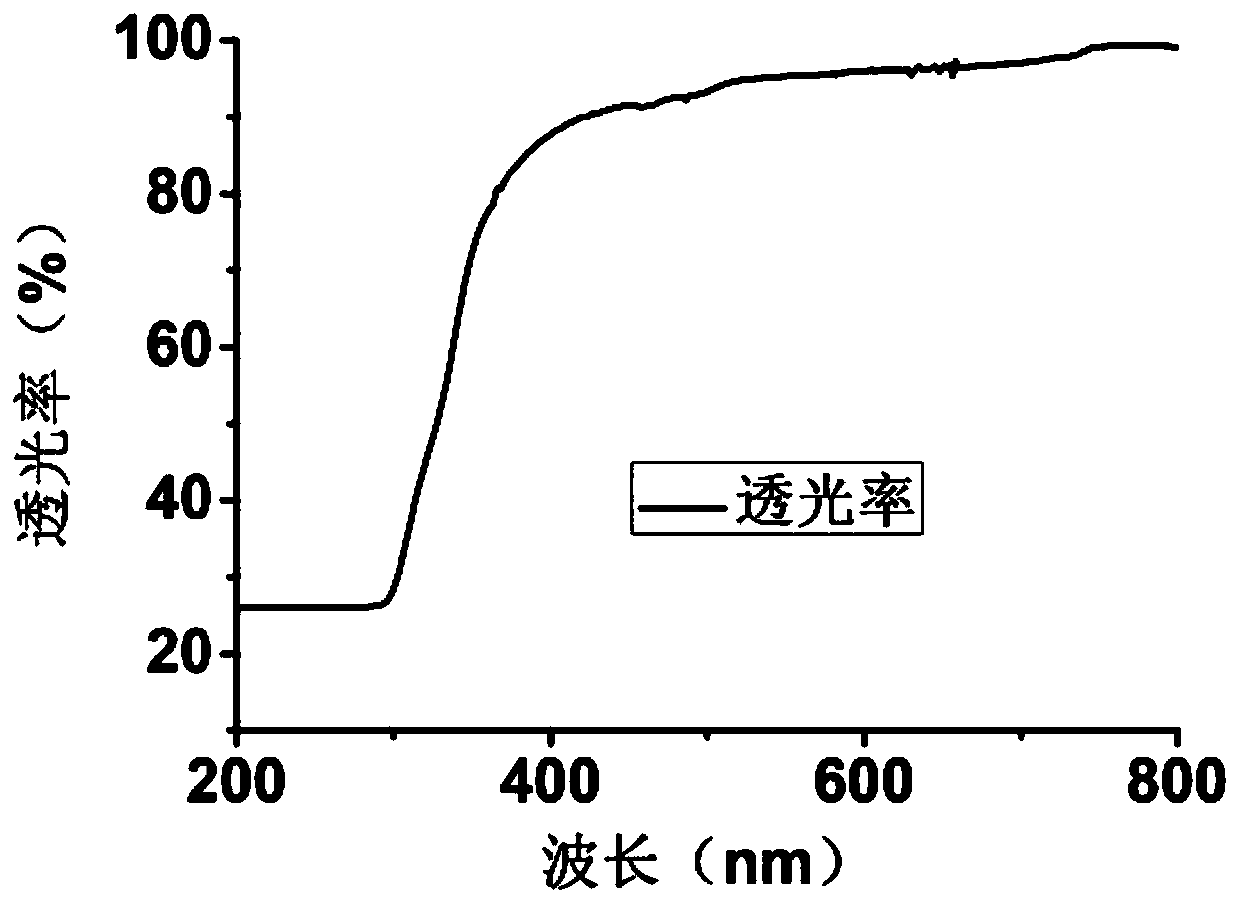

[0023] Take by weighing 2.0kg LDPE and 8.0g molybdenum vanadoxate metal cluster compound (its ultraviolet-visible absorption is as attached figure 1 shown) were mixed uniformly (the amount of the molybdenum vanadoxate metal cluster compound was 0.4wt%), and a 35-type granulator was used to prepare composite particles of LDPE and molybdenum vanadoxate metal cluster compound. A three-layer co-extrusion heavy packaging film unit is used for extrusion blow molding traction and winding, and a three-layer film is made by co-extrusion blow molding of composite particles and LDPE particles (as attached) figure 2 , where the UV-Vis transmission is shown in the attached image 3 shown), the extrusion temperature is 170°C, the inflation ratio is 3, and the draw ratio is 5. The obtained film is the anti-ultraviolet fruit and vegetable fresh-keeping film, which is marked as 0.4wt% molybdenum vanadium cluster-LDPE film.

Embodiment 2

[0025] Weigh and mix 2.5kg LDPE and 7.5g molybdenum vanadoxate metal clusters evenly (the amount of molybdenum vanadoxate metal clusters is 0.3wt%), and use a 35-type granulator to obtain LDPE and molybdenum vanadyl Composite particles of salt metal clusters. A three-layer co-extrusion heavy packaging film unit is used for extrusion blow molding traction and winding, and a three-layer film is made by co-extrusion blow molding of composite particles and LDPE particles (as attached) figure 2 shown), the extrusion temperature is 175°C, the inflation ratio is 3.2, and the draw ratio is 4.8. The obtained film is the anti-ultraviolet fruit and vegetable fresh-keeping film, which is marked as 0.3wt% molybdenum vanadium cluster-LDPE film.

Embodiment 3

[0027] Take by weighing 3.0kg LDPE and 6g molybdenum vanadoxate metal cluster compound and mix (the amount of molybdenum vanadoxate metal cluster compound is 0.2wt%), use 35 type granulators to make LDPE and molybdenum vanadoxate metal cluster compound Composite particles of salt metal clusters. A three-layer co-extrusion heavy packaging film unit is used for extrusion blow molding traction and winding, and a three-layer film is made by co-extrusion blow molding of composite particles and LDPE particles (as attached) figure 2 shown), the extrusion temperature is 170°C, the inflation ratio is 3.5, and the draw ratio is 5.5. The obtained film is the anti-ultraviolet fruit and vegetable fresh-keeping film, which is marked as 0.2wt% molybdenum vanadium cluster-LDPE film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com