POE adhesive film with high electrical strength and electrical tracking resistance and preparation method thereof

A technology of electric strength and electric tracking, which is applied in the field of solar cells, can solve problems such as low electric strength and electric tracking resistance index, electrical damage of components, power attenuation of components, etc., so as to improve electric strength and electric tracking resistance, reduce Electron conductance, the effect of increasing the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of preparation method of above-mentioned adhesive film, comprises the following steps:

[0049] (1), preparation of functional masterbatch: mix ethylene-vinyl acetate copolymer and ethylene-methyl methacrylate copolymer according to the formula amount, then add the formula amount photoinitiator and mix evenly, then add stabilizer and mix evenly, Under the condition that the processing temperature is 90-150°C, extrude, cool and pelletize to obtain functional masterbatch;

[0050] (2) Preparation of ethylene-octene copolymer modified particles: mix ethylene-octene copolymer, cross-linking agent, cross-linking accelerator and tackifier uniformly according to the formula to obtain a premix, pass the premix through The extruder performs reactive extrusion, and the extruded product is cooled, drawn, and pelletized into ethylene-octene copolymer modified particles;

[0051] (3), mix the functional masterbatch of step (1) and the ethylene-octene copolymer modified parti...

Embodiment 1

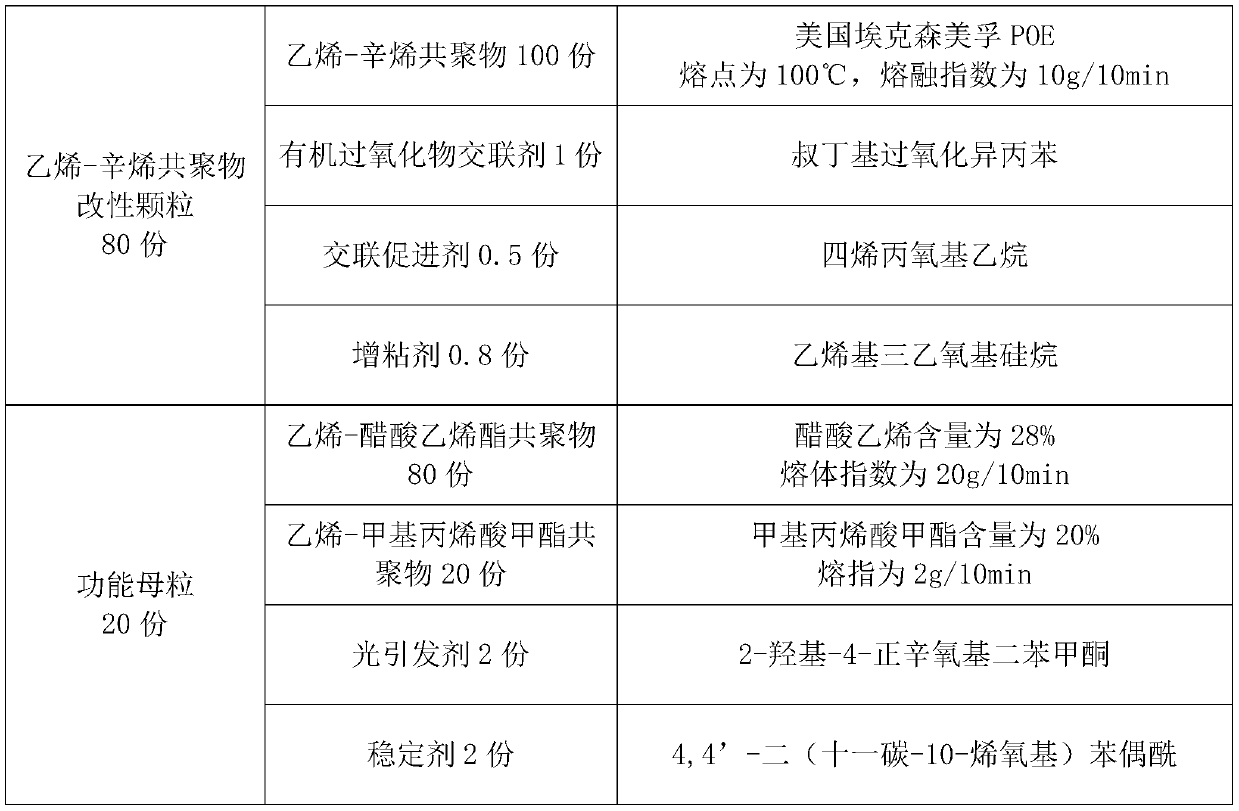

[0058] The formula of the POE adhesive film of this embodiment is shown in the following table in terms of raw materials in parts by weight.

[0059]

[0060] The preparation method of above-mentioned film, comprises the following steps:

[0061] (1), preparation of functional masterbatch: mix ethylene-vinyl acetate copolymer and ethylene-methyl methacrylate copolymer according to the formula amount, then add the formula amount of photoinitiator and mix evenly, then add stabilizer and mix evenly, Under the condition that the processing temperature is 90-150°C, extrude, cool and granulate to obtain functional masterbatch, pack the functional masterbatch in opaque packaging bags, and place it for more than 2 hours;

[0062] (2) Preparation of ethylene-octene copolymer modified particles: mix ethylene-octene copolymer, cross-linking agent, cross-linking accelerator and tackifier uniformly according to the formula to obtain a premix, pass the premix through A twin-screw extrud...

Embodiment 2

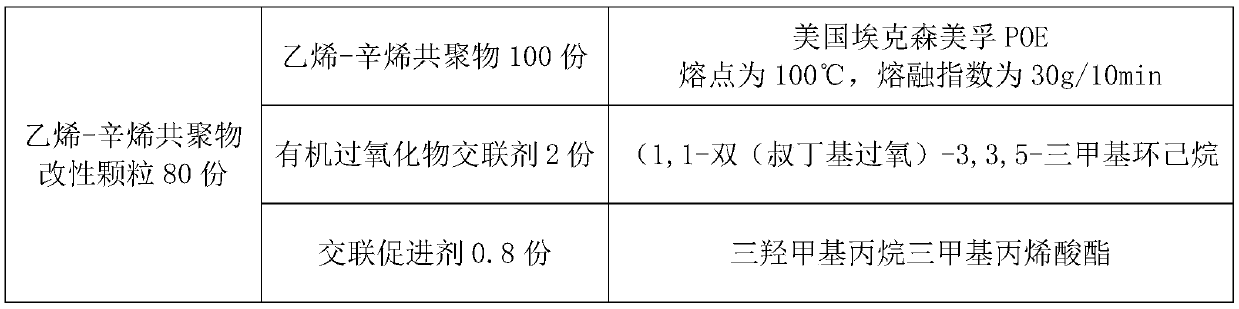

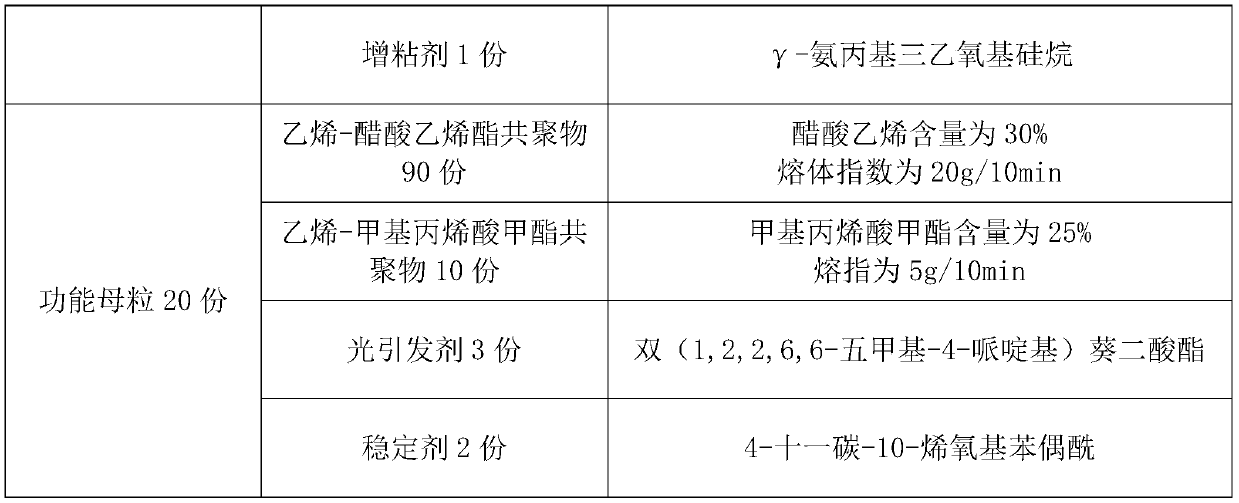

[0067] The POE film of this example and its preparation method are basically the same as those of Example 1, the difference lies in the formulation and preparation process parameters, as shown in the table below.

[0068] The formula of the POE adhesive film of this embodiment is shown in the following table in terms of raw materials in parts by weight.

[0069]

[0070]

[0071] The process parameters of POE film preparation are shown in the table below.

[0072] step 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com