Double-layer rotary tiller wear-resistant coating

A technology of wear-resistant coating and wear-resistant layer, which is applied in the field of wear-resistant coating of double-layer rotary tillage tools, can solve the problems of easy peeling off of the coating, environmental pollution, complicated process, etc., and achieve reduction of maintenance time and cost, wear-resistant The effect of high-strength improvement and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a wear-resistant coating for a double-layer rotary tillage tool, the specific steps are:

[0027] Step 1. Shot peen and sandblast the surface of the rotary tiller to remove oil and scale, and polish the cutting edge brightly;

[0028] Step 2. Put the WC powder and nickel-based brazing material with a mass ratio of 20%~50% into the mixer and mix them for 2 hours, take them out, and use a binder to prepare the two mixed powders into a paste to prepare the inner wear-resistant layer A ointment, spare;

[0029] Step 3: Put the diamond micropowder and nickel-based solder with a mass ratio of 10%~18% into the mixer and mix them for 2 hours, take them out, and use a binder to prepare the two mixed powders into a paste to obtain the outer wear-resistant layer B ointment, spare;

[0030] Step 4: Apply the inner layer wear-resistant layer A paste prepared in step 2 evenly on both sides and sides of the cutting edge of the rotary tiller, and control the th...

Embodiment 1

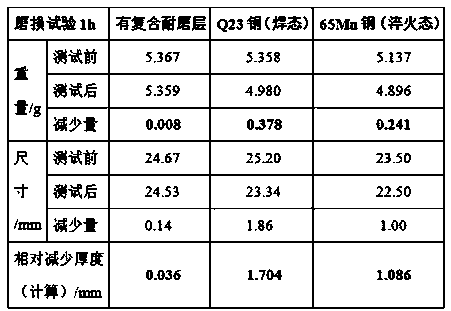

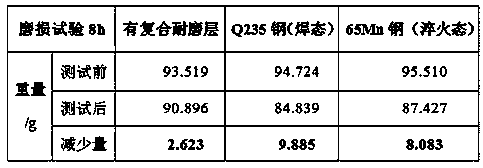

[0035] Select quenched 65Mn steel as the base material, carry out surface treatment such as shot blasting and sand blasting on the selected samples, remove oil and scale, polish the pre-coated wear-resistant layer brightly, and mix the mass ratio of 20%~50%WC powder Put it into the mixer with nickel-based brazing material and mix it for 2 hours, take it out, and use the binder to make the two kinds of mixed powder into a paste to prepare the inner wear-resistant layer A paste, which is set aside; the mass ratio is 10%~18% Put the diamond micropowder and nickel-based brazing material into the mixer and mix for 2 hours, then take them out, and use a binder to prepare the two mixed powders into a paste to prepare the outer wear-resistant layer B paste, which is set aside; the prepared inner layer The wear-resistant layer A paste is evenly coated on the surface-treated specimens with specifications of ϕ6mm×25mm, 25mm×5mm×100mm and the rotary tiller, and the thickness is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com