Detector adopting acoustic resonator and carbon nanotube and manufacturing method thereof

A technology of acoustic wave resonators and carbon nanotubes, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of limiting the performance of uncooled bolometers and limiting the high frequency of thermal detectors Performance, limited performance of thermal detectors, etc., to achieve good detection performance, save circuit components, and small heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

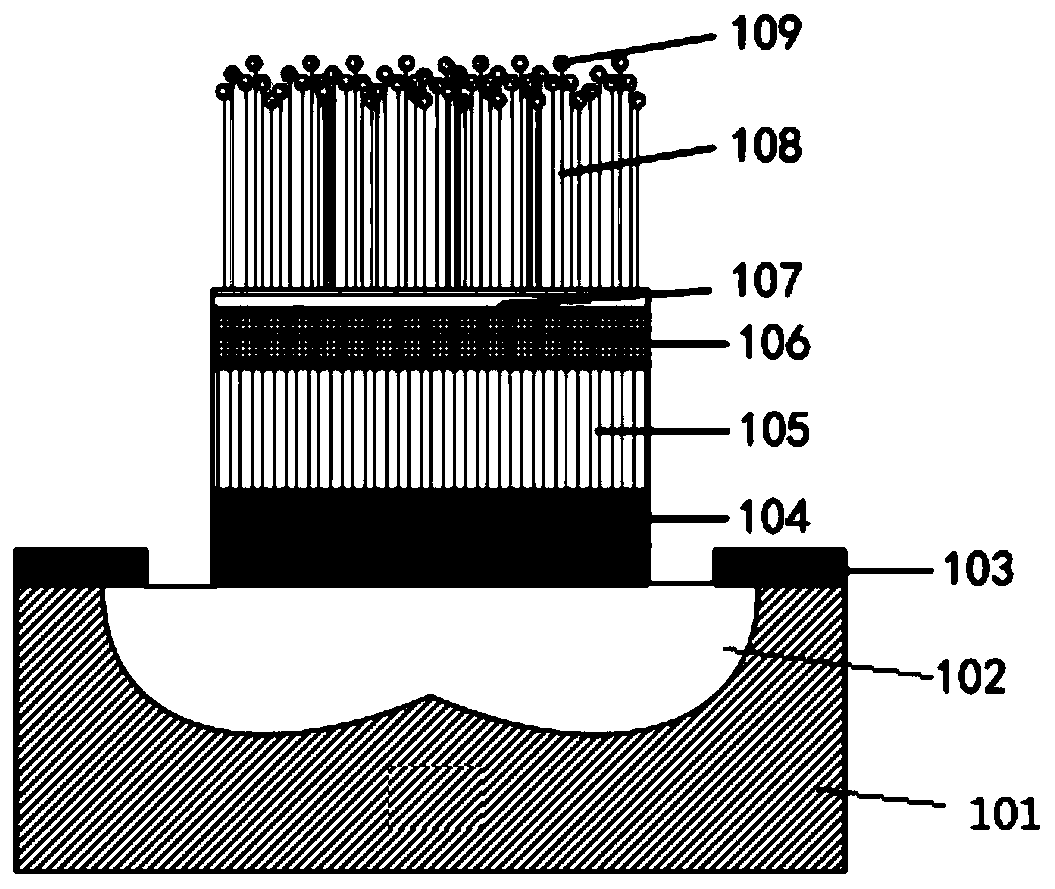

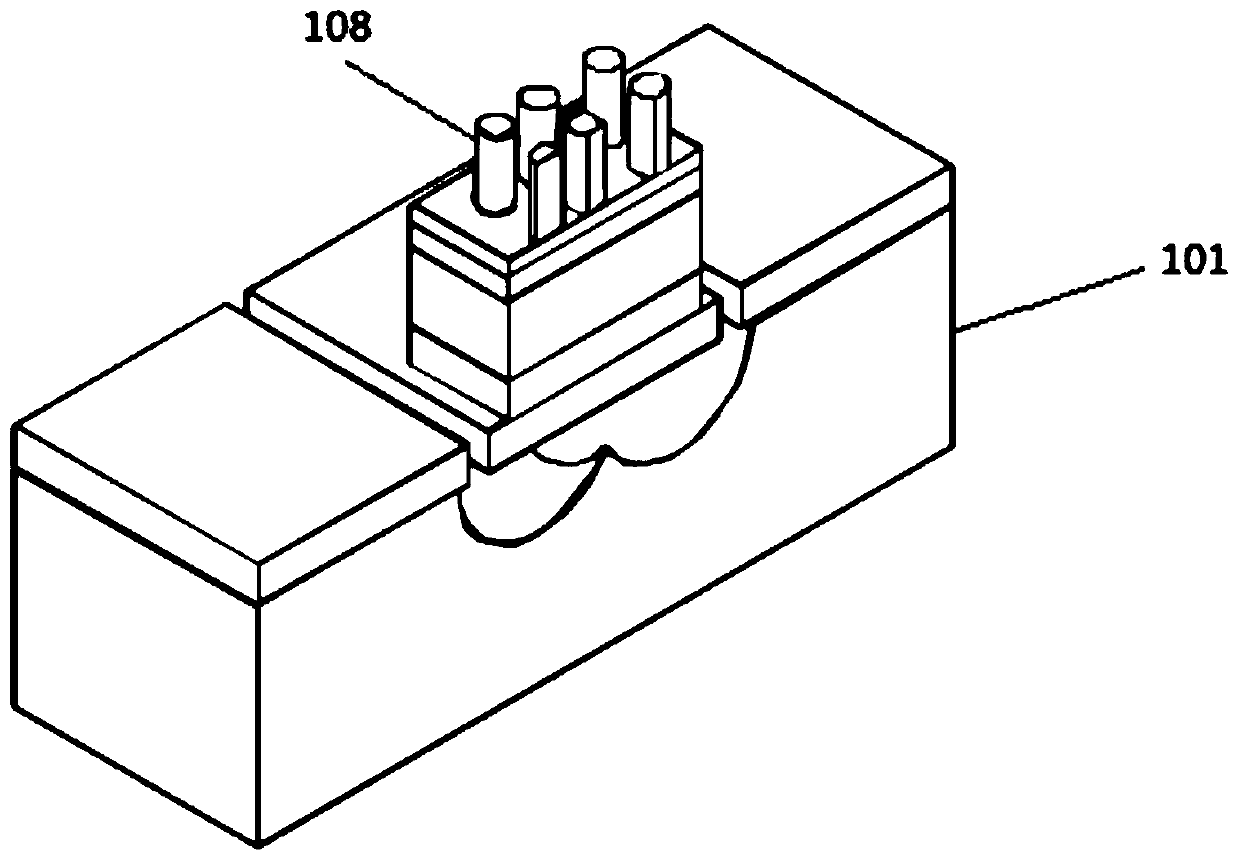

[0035] Such as Figure 1 to Figure 5 As shown, a detector using an acoustic wave resonator and carbon nanotubes described in the present invention includes an acoustic wave resonator, and the described acoustic wave resonator includes a substrate 101, and a part of the acoustic wave resonator far away from the substrate 101 Carbon nanotubes 108 are provided on the side.

[0036] The acoustic wave resonator also includes a resonant structure disposed on the substrate 101, and the resonant structure includes a silicon dioxide layer 103, a bottom electrode 104, a piezoelectric film 105 and a top electrode 106 stacked on the substrate 101 in sequence The substrate 101 is provided with a cavity 102 at the position where the resonant structure is provided; a graphene interconnection layer 107 is provided between the top electrode 106 and the carbon nanotubes 108 .

[0037] The cross-section of the cavity 102 is arc-shaped, and the middle part of the cavity 102 protrudes toward the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com