A preparation method and application of three-dimensional porous biochar derived from cones

A three-dimensional porous and biochar technology, applied in the fields of energy, environment, and materials, can solve problems such as general biocompatibility, limited power density, and small specific surface area, and achieves simple and easy methods, high voltage and power density, and biological good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

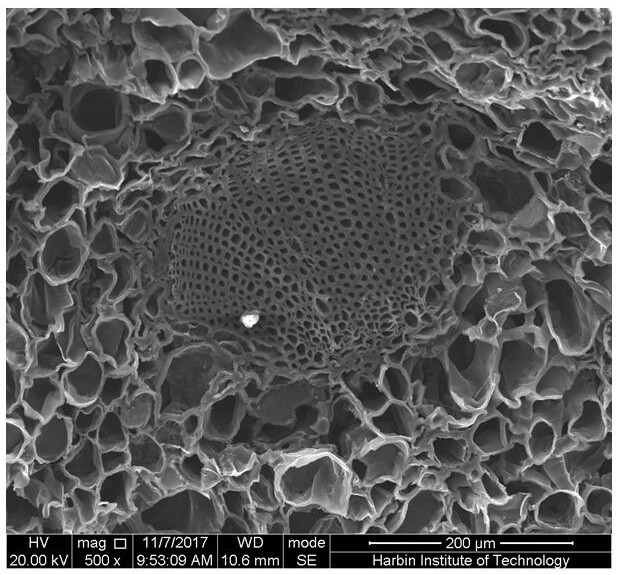

[0027] (1) Clean up the sundries on the surface of the collected pine cones and dry them at room temperature for 12 h.

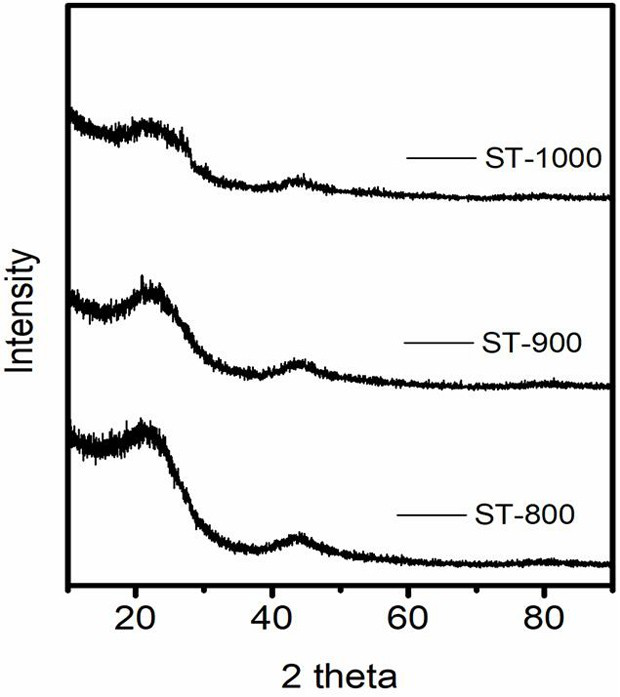

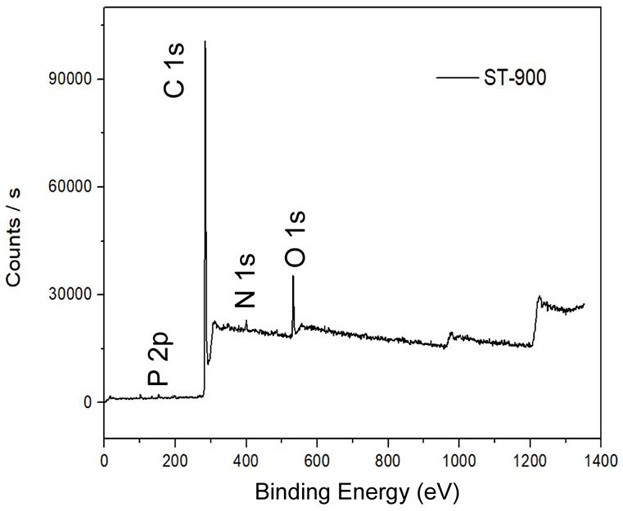

[0028] (2) Put the dried pine cones into a tube furnace, raise the temperature to 800°C at a rate of 1.5°C / min in a nitrogen atmosphere, maintain it for 2 hours, then cool it down to room temperature naturally, and take it out to obtain a three-dimensional porous organism carbon material.

[0029] (3) The three-dimensional porous biochar material was washed several times in water and ethanol solution, and it was wound with titanium wire as the MFC anode material. Limitations of battery configuration and anolyte.

Embodiment 2

[0031] The difference between this example and Example 1 is that the cleaned cones are dried in vacuum for 30 minutes, the dried cones are placed in a tube furnace, and the temperature is raised at a heating rate of 1.5°C / min under a nitrogen atmosphere. Keep it at 900°C for 4 hours, then cool it down to room temperature naturally and take it out.

Embodiment 3

[0033] The difference between this embodiment and embodiment 1 is that the heating rate is 5° C. / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com