Self-floating thermal insulation water-guiding material and preparation method and application thereof

A thermal insulation material, selected technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of low mechanical strength, large-scale application gap, complex preparation process, etc., and achieve improved photothermal evaporation Excellent efficiency and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The invention provides a preparation method of heat-insulating and water-conducting material, which comprises the following steps:

[0077] (1) mixing the crosslinking agent with the polyvinylpyrrolidone to obtain a mixed powder;

[0078] (2) dissolving the mixed powder described in step (1) in an organic solvent to obtain a casting solution;

[0079] (3) adding the casting solution described in step (2) into the heat insulating material to obtain the slurry;

[0080] (4) Pressing the slurry described in step (3), and then performing phase inversion to obtain a heat-insulating and water-conducting material.

[0081] In a preferred embodiment of the present invention, wherein the organic solvent is selected from one or more of N,N-dimethylacetamide, acetone and N,N-dimethylformamide .

[0082] In a more preferred embodiment of the present invention, wherein, the mass ratio of the crosslinking agent to the organic solvent is 5-25:100, preferably 8-24:100, more preferab...

Embodiment 1

[0104] Embodiment 1 Preparation of heat-insulating and water-conducting material

[0105] (1) 8g polyvinylidene fluoride (PVDF) and 1g polyvinylpyrrolidone (PVP) are mixed uniformly to obtain mixed powder;

[0106] (2) Uniformly disperse the mixed powder described in step (1) in 49 g of N,N-dimethylacetamide (DMAc), stir to dissolve, mix for 12 hours, ultrasonicate for 30 minutes, and stand for 48 hours for defoaming to obtain yellow Transparent casting fluid.

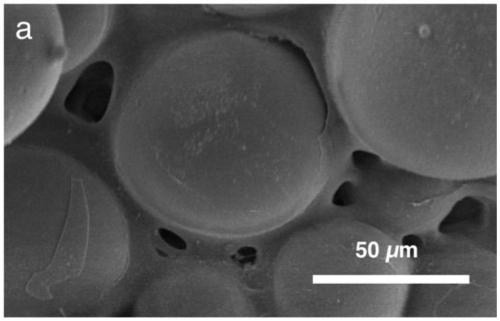

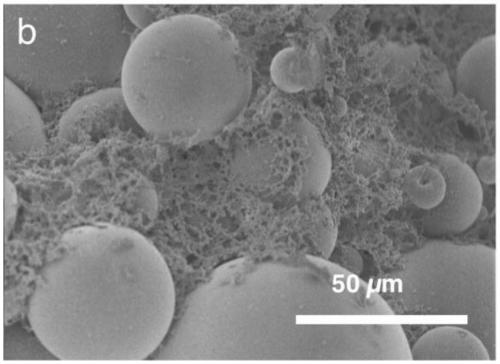

[0107] (3) Weigh 3g of hollow glass microspheres (average particle size 55 μm), add 10mL of the casting solution described in step (3) into the hollow glass microsphere powder, stir evenly with a glass rod, and use a pestle to Repeatedly beat and knead to obtain a viscous dough-like slurry;

[0108] (4) Pour the above slurry into a pre-prepared mold (5*4*0.6cm), press it under a pressure of 2MPa and keep it for 5min, take it out, transfer it into a constant temperature water 30°C water bath to undergo a phase inversi...

Embodiment 2

[0113] Example 2 Preparation of a simple light-to-heat conversion device

[0114] The self-floating thermal insulation and water-conducting material prepared in Example 1 floats on the water surface, and a layer of light-to-heat conversion film (which is made by dispersing carbon black in cellulose acetate N,N-dimethylethyl ether) is pasted on the water surface. amide solution, scrape coating or spin coating, and phase inversion in water) to obtain a complete light-to-heat conversion device. The schematic diagram of the light-to-heat conversion device is shown in image 3 As shown, its composition mainly includes four components: an open container, the water contained in it, a self-floating heat-insulating and water-conducting material, and a light-to-heat conversion film.

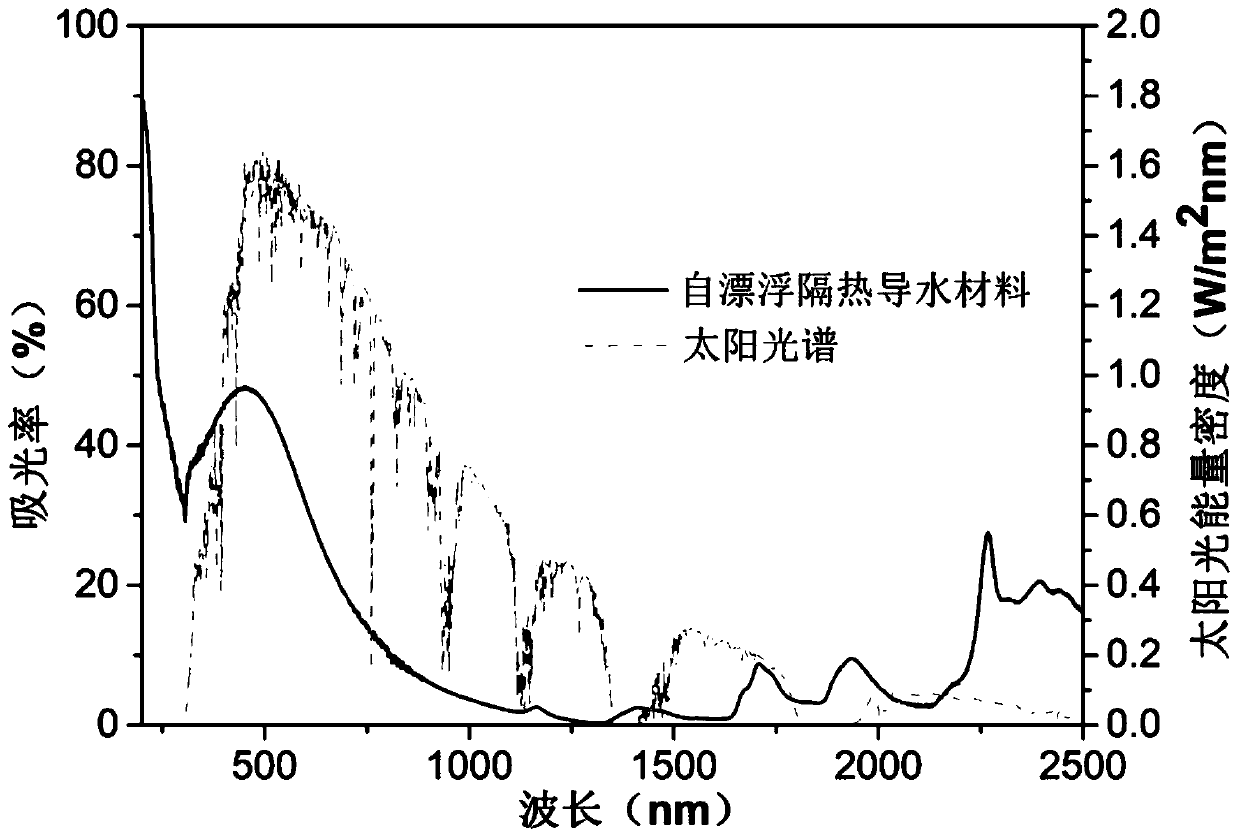

[0115] The simple photothermal conversion device obtained in embodiment two is carried out the mensuration of following performance:

[0116] 1) Test of light-to-heat conversion performance

[0117] Use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com