A kind of high-performance V-belt and its preparation method

A V-belt, high-performance technology, applied in belts, V-belts, mechanical equipment, etc., can solve problems such as poor bonding strength and poor performance of V-belts, and improve physical and mechanical properties and bending resistance, Effects of increasing stress such as tension and increasing reaction energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

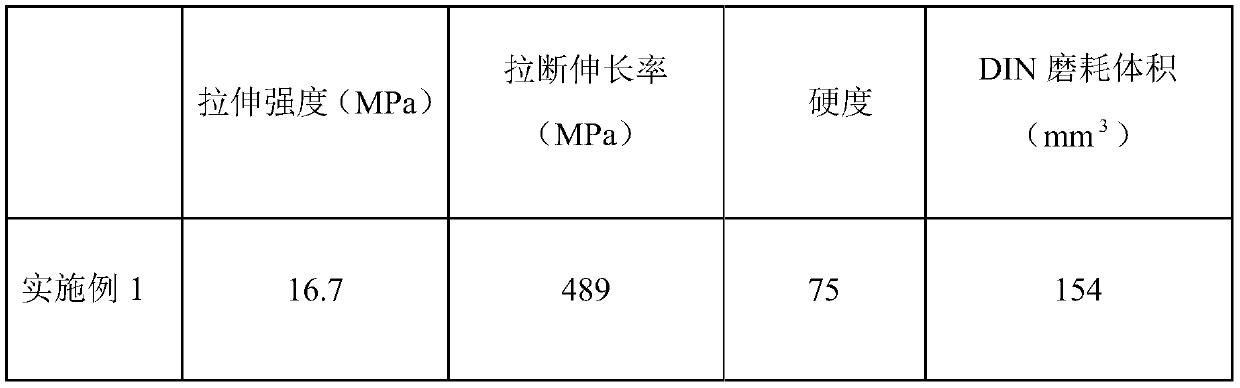

Embodiment 1

[0032] A high-performance V-belt according to this embodiment, the V-belt includes a strength layer, the upper part of the strength layer is provided with a stretch layer, the lower part of the strength layer is provided with a compression layer, and the outside of the tension layer and the compression layer is wrapped with a wrapping layer;

[0033] The strength layer is surface-modified tempered brown silk;

[0034] The stretch layer includes the following raw materials in parts by weight:

[0035] 40 parts of neoprene rubber, 5 parts of natural rubber, 10 parts of polyurethane resin, 10 parts of talcum powder, 4 parts of aromatic oil, 3 parts of sodium tripolyphosphate.

[0036] The preparation method of the surface-modified toughened brown silk in this embodiment is to soak the toughened brown silk in nitric acid solution for 1 hour, then take it out and rinse it with deionized water, then air-dry it, and then place it in a 10% sodium hydroxide solution In the process, us...

Embodiment 2

[0050] A high-performance V-belt according to this embodiment, the V-belt includes a strength layer, the upper part of the strength layer is provided with a stretch layer, the lower part of the strength layer is provided with a compression layer, and the outside of the tension layer and the compression layer is wrapped with a wrapping layer;

[0051] The strength layer is surface-modified tempered brown silk;

[0052] The stretch layer includes the following raw materials in parts by weight:

[0053] 50 parts of neoprene rubber, 15 parts of natural rubber, 20 parts of polyurethane resin, 20 parts of talcum powder, 10 parts of aromatic oil, 9 parts of sodium tripolyphosphate.

[0054] The preparation method of the surface-modified toughened brown silk in this embodiment is to soak the toughened brown silk in nitric acid solution for 2 hours, then take it out and rinse it with deionized water, then air-dry it, and then place it in a 10% sodium hydroxide solution In the process,...

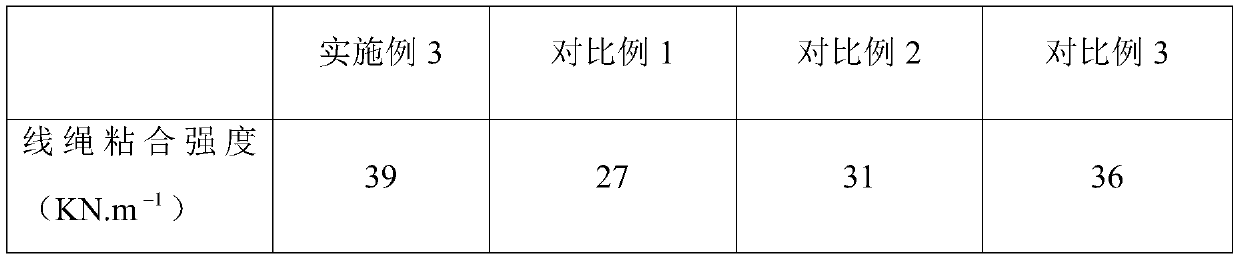

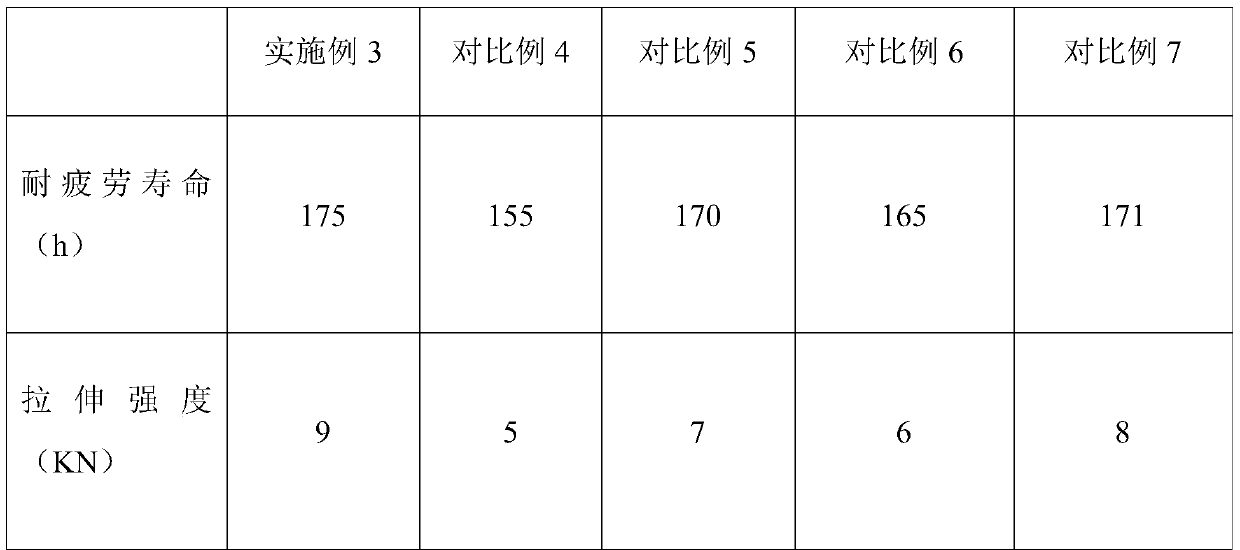

Embodiment 3

[0068] A high-performance V-belt according to this embodiment, the V-belt includes a strength layer, the upper part of the strength layer is provided with a stretch layer, the lower part of the strength layer is provided with a compression layer, and the outside of the tension layer and the compression layer is wrapped with a wrapping layer;

[0069] The strength layer is surface-modified tempered brown silk;

[0070] The stretch layer includes the following raw materials in parts by weight:

[0071] 45 parts of neoprene rubber, 10 parts of natural rubber, 15 parts of polyurethane resin, 15 parts of talcum powder, 7 parts of aromatic oil, 4.5 parts of sodium tripolyphosphate.

[0072] The preparation method of the surface-modified toughened brown silk of the present embodiment is to soak the toughened brown silk in nitric acid solution for 1.5 hours, then take it out and rinse it with deionized water, then air-dry it, and then place it in 10% sodium hydroxide In the solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com