Method for improving edible quality of whole-grain coarse cereals

A technology of whole grains and miscellaneous grains, which is applied in the direction of food science, etc., can solve the problems of difficult cooking, difficult industrialization, and complicated process of whole grains and miscellaneous grains, and achieve the effects of soft stickiness, rapid ripening, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

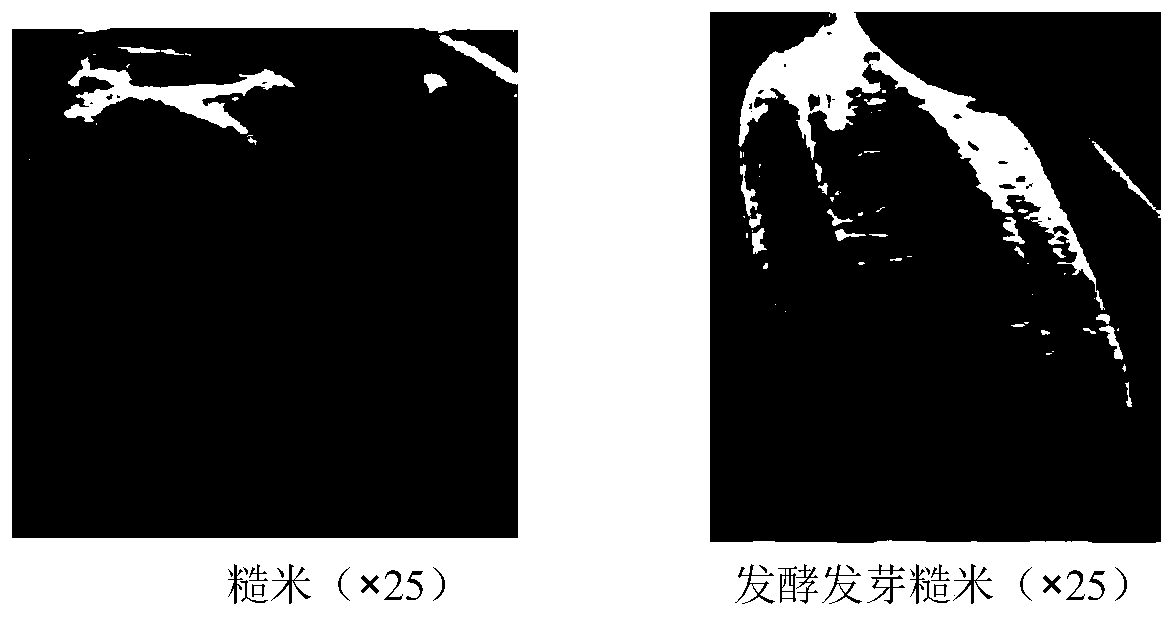

Image

Examples

Embodiment 1

[0019] (1) soaking, germination:

[0020] Soak 10kg of selected and washed brown rice in 19kg of water at 28°C for 12 hours, then drain the water and place it in a germination tank; the temperature is controlled at 28°C, cultivated for 48 hours, rinsed every 6 hours during the period, and ventilated every hour Once to keep enough oxygen in the germination tank; after the germination is completed, rinse the brown rice sprouts with water, dehydrate them by centrifugation, and enter the fermentation tank;

[0021] (2) Inoculation and fermentation The fermented bacteria liquid is evenly sprayed on the brown rice at the top of the fermenter according to the dry weight of brown rice (absolutely dry) 5%, and the fermentation temperature is controlled at 38° C., and fermented for 12 hours;

[0022] The fermented bacteria liquid is Lactobacillus plantarum and Lactobacillus rhamnosus with a volume ratio of 1:1, and the content of Lactobacillus plantarum is 10 8 CFU / 100mL, the content o...

Embodiment 2

[0032] (1) soaking, germination:

[0033] Soak 10kg of selected and washed brown rice in 19kg of water at 28°C for 12 hours, then drain the water and place it in a germination tank; the temperature is controlled at 28°C, cultivated for 48 hours, rinsed every 6 hours during the period, and ventilated every hour Once to keep enough oxygen in the germination tank; after the germination is completed, rinse the brown rice sprouts with water, dehydrate them by centrifugation, and enter the fermentation tank;

[0034] (2) Inoculation and fermentation will ferment the bacterium liquid, and the fermented bacterium liquid is Lactobacillus plantarum, wherein the content of Lactobacillus plantarum is 10 8 CFU / 100mL, according to the dry weight of brown rice (dry) 5%, evenly spray on the brown rice on the top of the fermenter, and control the fermentation temperature at 38°C, and ferment for 12 hours;

[0035] (3) dry

[0036] Using a fluidized bed dryer, the fluidization temperature is ...

Embodiment 3

[0044] (1) soaking, germination:

[0045] Soak 10kg of selected and washed brown rice in 12kg of water at 28°C for 12 hours, then drain the water and place it in a germination tank; the temperature is controlled at 26°C, cultivated for 60 hours, rinsed every 6 hours during this period, and ventilated every hour Once to keep enough oxygen in the germination tank; after the germination is completed, rinse the brown rice sprouts with water, dehydrate them by centrifugation, and enter the fermentation tank;

[0046] (2) Inoculation and fermentation The fermented bacteria liquid is evenly sprayed on the brown rice on the top of the fermenter according to the dry weight of brown rice (absolutely dry) 3%, and the fermentation temperature is controlled at 35° C., and fermented for 18 hours;

[0047] The fermented bacteria liquid is Lactobacillus plantarum and Lactobacillus rhamnosus with a volume ratio of 1:1, wherein the content of Lactobacillus plantarum is 10 8 CFU / 100mL, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com