Ethyl acetate recovery method using activated carbon adsorption combined with rotor adsorption

A technology of activated carbon adsorption and activated carbon adsorption tank, which is applied in the field of organic waste gas treatment, can solve the problems of increased sewage treatment cost, secondary pollution, and short activated carbon switching cycle, so as to avoid the cost of sewage treatment, increase the degree of adsorption saturation, and avoid fire risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

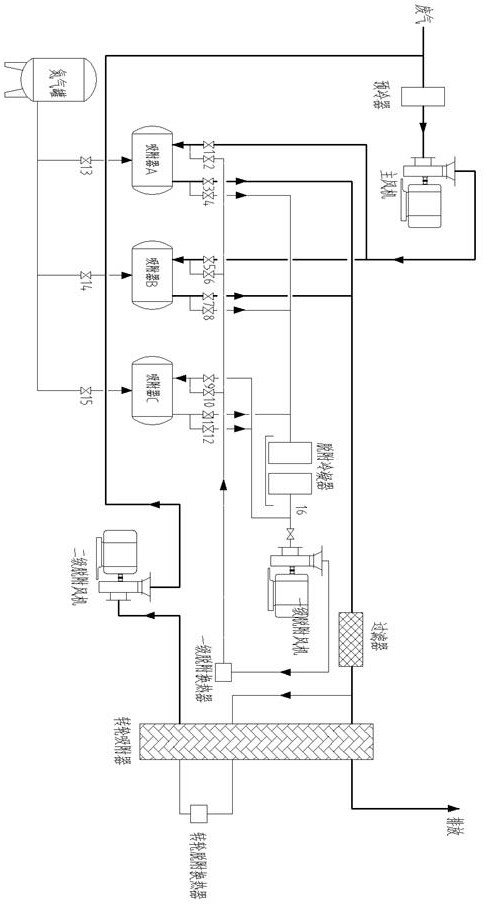

[0020] Embodiment 1: with reference to attached figure 1 . An ethyl acetate recovery system that combines activated carbon adsorption with rotor adsorption, including a precooler, main fan, activated carbon adsorption tank A, activated carbon adsorption tank B, activated carbon adsorption tank C, filter, desorption condensation Device, primary desorption fan, rotary adsorber, primary desorption heat exchanger, rotary desorption heat exchanger, secondary desorption fan, nitrogen tank.

[0021] Pre-cooling of organic waste gas: The workshop waste gas and the organic waste gas regenerated by the runner enter the precooler for adsorption precooling to reduce the temperature of the organic waste gas to 20-30°C.

[0022] Adsorption of organic waste gas: The organic waste gas transported by the fan enters the activated carbon adsorber A for waste gas adsorption. The adsorbed waste gas is filtered through the filter, and the filtered gas enters the rotary adsorber for adsorption, and...

Embodiment 2

[0031]Embodiment 2: on the basis of embodiment 1, adopt the ethyl acetate recovery method that gac adsorption combines with runner adsorption, comprise the following steps:

[0032] Step 1: The organic waste gas circulated by the workshop and the runner is pre-cooled by the condenser, and the treated organic waste gas enters and exits the activated carbon adsorption tank A for adsorption, and the adsorbed organic waste gas enters the runner for adsorption and concentration, and the qualified gas enters the atmosphere middle discharge.

[0033] Step 2: When the discharge outlet concentration of the runner exceeds the set value, close and open the corresponding valve, so that the adsorber A enters the desorption stage, the adsorption tank B enters the primary adsorption stage, and the adsorption tank C performs the secondary adsorption. During this process, the rotor has been carrying out the process of solvent adsorption and regeneration of the rotor.

[0034] Step 3: The ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com