Suspended bed and fixed bed combined desulfurization technology

A desulfurization process and suspended bed technology, applied in the field of desulfurization, can solve the problems of low desulfurization efficiency, complicated process flow and equipment, etc., and achieve the effects of high desulfurization efficiency, low price and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The combined desulfurization process of a suspended bed and a fixed bed provided in this embodiment includes the following steps:

[0048] (1) Mix magnetic iron oxide with a particle size of 1 to 20 μm and water evenly in a certain proportion, and prepare a desulfurization slurry with a concentration of 1 wt %;

[0049] (2) H 2 The S content is 71.2g / Nm 3 The biogas mixed with the desulfurization slurry enters the first-stage suspended bed reactor with a superficial gas velocity of 0.3m / s from bottom to top, and the residence time of the desulfurization slurry in the first-stage suspended bed reactor is controlled to 5-7min The mixture discharged from the top of the first-stage suspended bed reactor enters the second-stage suspended-bed reactor with a superficial gas velocity of 0.3m / s from the bottom again, and the residence time of the desulfurization slurry in the second-stage suspended-bed reactor is controlled to be 5min. To make the biogas and the desulfurizatio...

Embodiment 2

[0053] The combined desulfurization process of a suspended bed and a fixed bed provided in this embodiment includes the following steps:

[0054] (1) Mix ferric hydroxide with a particle size of 5-15 μm and water uniformly in a certain proportion, and prepare a desulfurization slurry with a concentration of 2wt%;

[0055] (2) H 2 S content is 2.4g / Nm 3 The coke oven gas mixed with the above-mentioned desulfurization slurry enters from bottom to top into the suspension bed reactor with a superficial gas velocity of 0.15m / s, and the residence time of the desulfurization slurry in the suspension bed reactor is controlled to be 6-8min. Make the coal gas and the desulfurization slurry fully contact and react in the suspended bed reactor;

[0056] (3) Carry out gas-liquid separation to the gas-solid-liquid three-phase mixture discharged from the top of the suspended bed reactor, collect the gas phase and the rich liquid respectively, and measure the H in the gas phase 2 The S con...

Embodiment 3

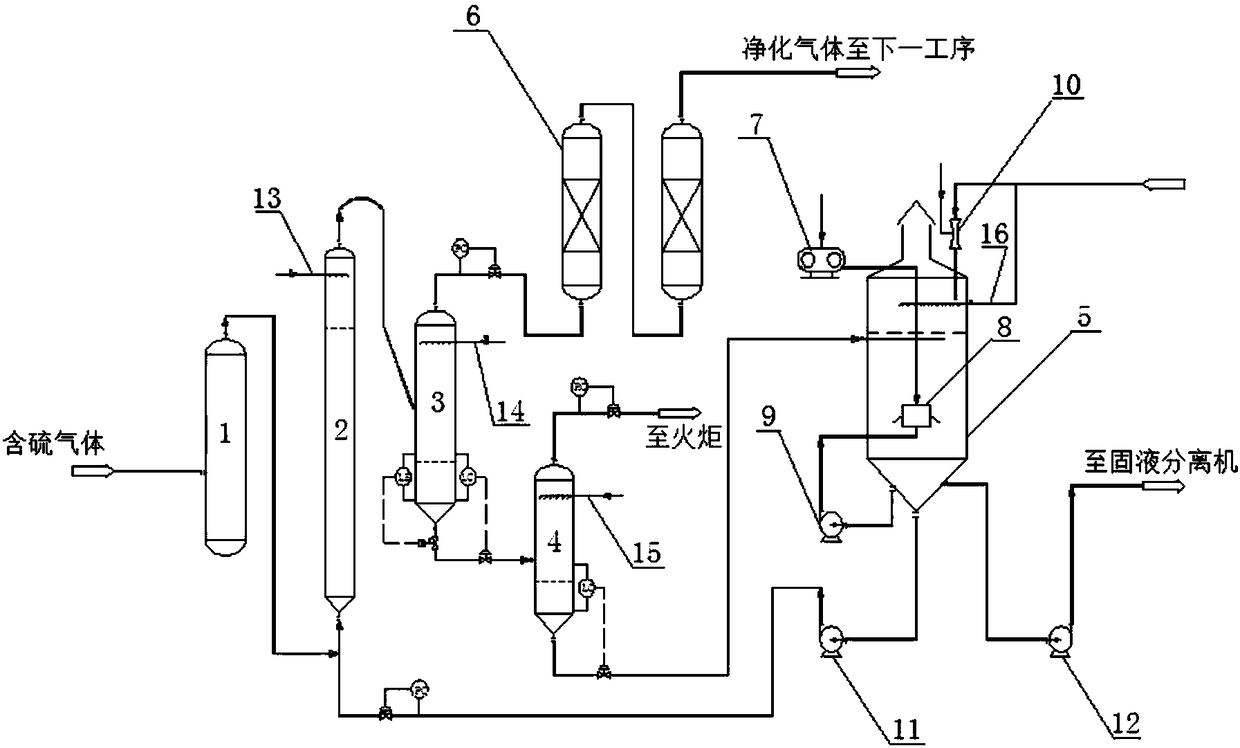

[0059] Such as figure 1 As shown, the combined desulfurization process of a suspended bed and a fixed bed provided in this embodiment includes the following steps:

[0060] (1) Mixing amorphous iron oxyhydroxide with a particle size of 5-20 μm and water uniformly in a certain proportion to prepare a desulfurization slurry with a concentration of 2.5 wt %;

[0061] (2) H 2 S content is 140g / Nm 3 The natural gas from the coalescing tank is sent to the coalescing tank to remove heavy components above C5. The natural gas from the coalescing tank is mixed with the desulfurization slurry and then enters the suspension bed reactor with a superficial gas velocity of 0.2m / s from bottom to top. Control the residence time of the desulfurization slurry in the suspended bed reactor to 30-35 minutes, so that the natural gas and the desulfurization slurry can fully contact and react in the suspended bed reactor;

[0062] (3) Carry out gas-liquid separation to the gas-solid-liquid three-ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com