Method for recycling sulfur and silver of zinc oxygen-pressure leaching residue

A technology for leaching slag and zinc oxide, which is applied in the direction of chemical instruments and methods, sulfur compounds, process efficiency improvement, etc., can solve the problems of low recovery rate of elemental sulfur, large amount of slag, high energy consumption of sulfur, etc. The effect of recovery rate and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

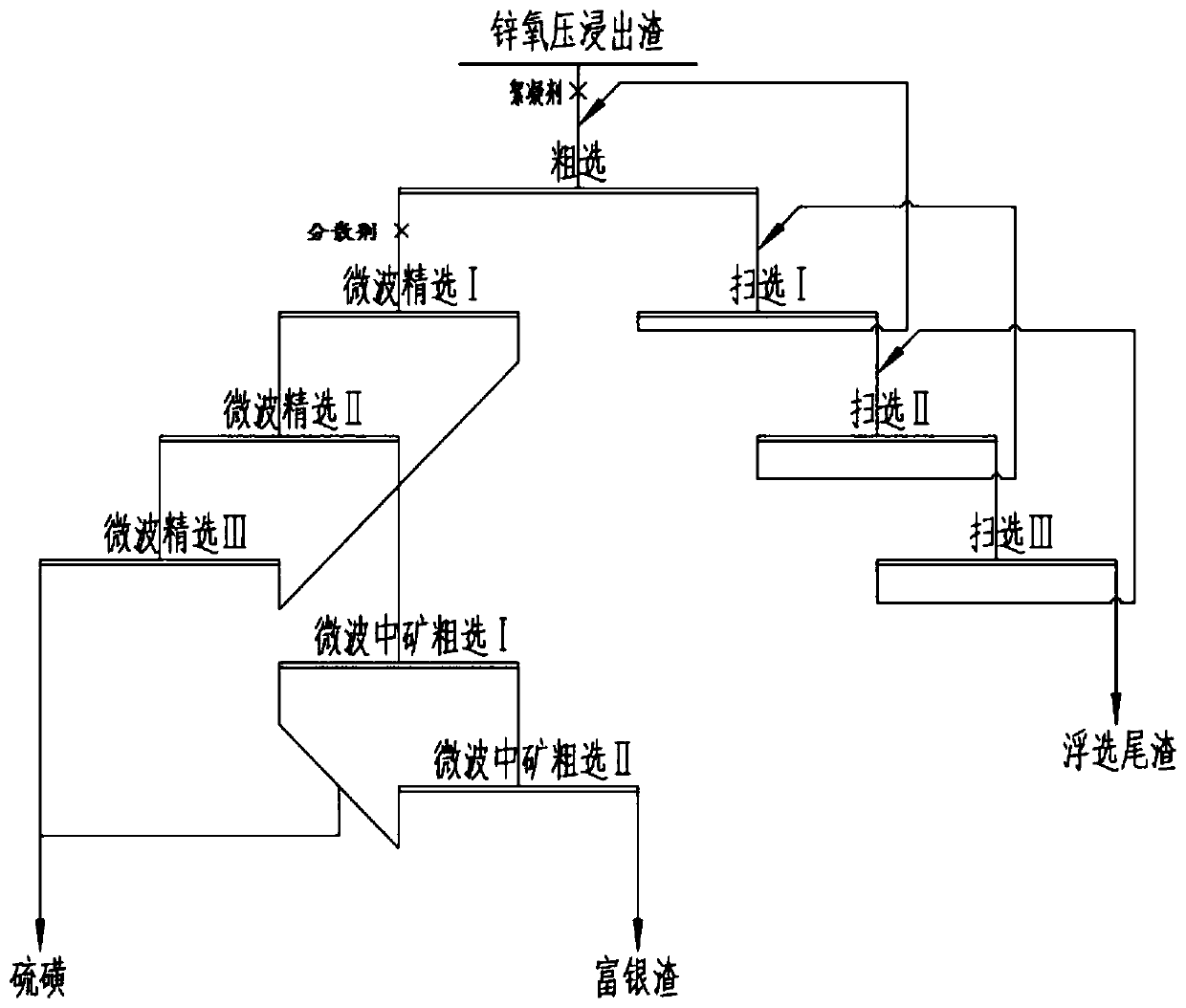

[0028] The invention provides a method for recovering sulfur and silver from zinc oxygen pressure leaching slag, comprising the following steps:

[0029] (1) After zinc oxygen pressure leaching, the zinc concentrate is preliminarily dehydrated in a thickener to obtain a zinc oxygen pressure leaching slag slurry with a concentration of 32%, which contains 4.5% zinc, 250g / t silver, 6.2% lead, and 13%, sulfur 60%;

[0030] (2) Add polyacrylamide to the zinc oxygen pressure leaching slag slurry prepared in step (1), the addition amount is 65g / t, control the rotating speed and maintain the thickness of the foam layer, and carry out roughing to obtain roughing concentrate and roughing tailings mine;

[0031] (3) add lignin to the roughing concentrate prepared in step (2), the addition is 50g / t, carry out three sections of selection, carry out microwave treatment in the selection process, three sections of selection microwave power are respectively 800W, 1200W, 1600W, the microwave...

Embodiment 2

[0035] The invention provides a method for recovering sulfur and silver from zinc oxygen pressure leaching slag, comprising the following steps:

[0036] (1) After zinc oxygen pressure leaching, the zinc concentrate is preliminarily dehydrated in a thickener to obtain a zinc oxygen pressure leaching slag slurry with a concentration of 40%, which contains 3.2% zinc, 330g / t silver, 5.6% lead, and iron 44%, sulfur 35%;

[0037] (2) Add starch to the zinc oxygen pressure leaching slag slurry prepared in step (1), the addition amount is 80g / t, control the rotating speed and maintain the thickness of the foam layer, and carry out roughing to obtain roughing concentrate and roughing tailings;

[0038] (3) add water glass to the rougher concentrate prepared in step (2), the addition is 100g / t, carry out three sections of selection, carry out microwave treatment in the selection process, three sections of selection microwave power are respectively 1000W, 1300W, 1800W, the microwave fr...

Embodiment 3

[0042] The invention provides a method for recovering sulfur and silver from zinc oxygen pressure leaching slag, comprising the following steps:

[0043] (1) After the zinc concentrate is leached by oxygen pressure, it is preliminarily dehydrated in a thickener to obtain a zinc oxygen pressure leaching slag slurry with a concentration of 23%, which contains 2.1% zinc, 120g / t silver, 3.4% lead, and iron 52%, sulfur 52%;

[0044](2) Add polyacrylamide to the zinc oxygen pressure leaching slag slurry prepared in step (1), the addition amount is 20g / t, control the rotating speed and maintain the thickness of the foam layer, and carry out roughing to obtain roughing concentrate and roughing tailings mine;

[0045] (3) Add lignin to the roughing concentrate prepared in step (2), the addition is 70g / t, carry out three sections of selection, carry out microwave treatment in the selection process, three sections of selection microwave power are respectively 1200W, 1400W, 1600W, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com