Method for judging and treating anaerobic particle sludge poisoning

A technology of sludge and sludge granules, which is applied in the direction of sludge treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problem of inaccurate judgment methods, inaccurate response to anaerobic granular sludge poisoning, and difficult Realization and other issues, to achieve the effect of shortening the processing cycle, shortening the granulation process, and shortening the start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

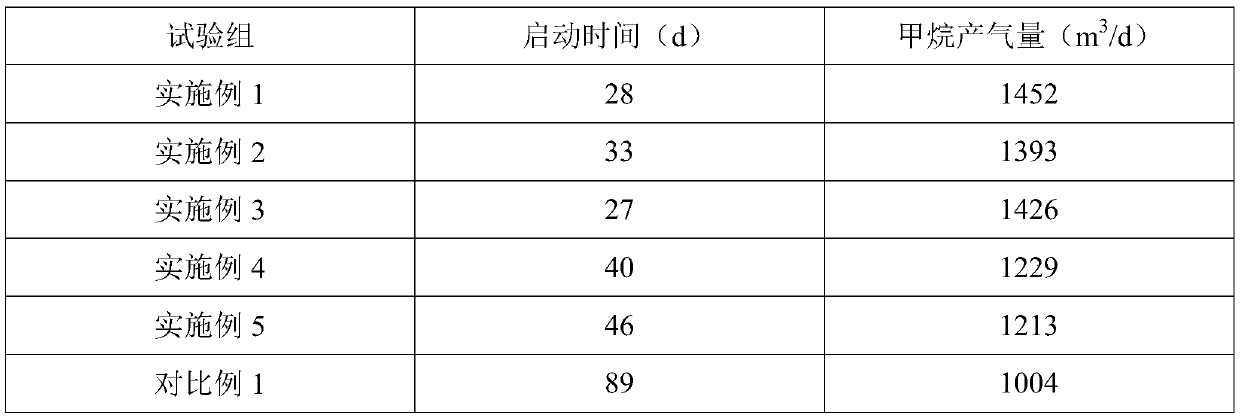

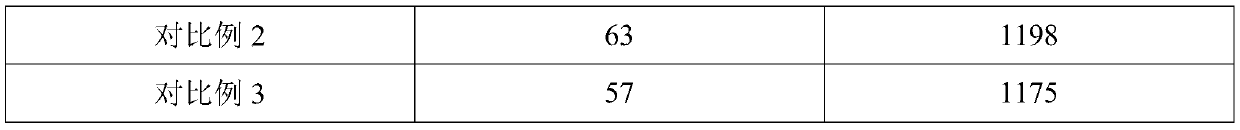

Examples

Embodiment 1

[0040] (1) In the anaerobic reactor of the papermaking sewage treatment system (the volume specification of the IC anaerobic reactor is 2200m 3 , the following embodiments are all the same) the gas outlet is connected to a carbon dioxide detector to detect the amount of carbon dioxide produced;

[0041] (2) When the carbon dioxide flow is unstable and the pH value of the reactor outlet changes, the poisoned and rancid sludge is discharged from the sludge discharge valve at the bottom of the reactor;

[0042] (3) Stop the water intake, and introduce 15% of the normal granular sludge of the effective volume of the reactor;

[0043] (4) Control the water intake to 150m 3 / h and strengthen the reflux cycle;

[0044] (5) The ascending velocity in the control reactor is 5m / h;

[0045] (6) Add the cationic polyacrylamide of 30mg / L every two days in the anaerobic reactor;

[0046] (7) When the COD removal rate is 80%, the FeCl of 0.5mg / L 2 added to the reactor;

[0047] (8) Dete...

Embodiment 2

[0049] (1) Connect a carbon dioxide detector to the gas outlet of the anaerobic reactor of the papermaking sewage treatment system to detect the amount of carbon dioxide produced;

[0050] (2) When the carbon dioxide flow is unstable and the pH value of the reactor outlet changes, the poisoned and rancid sludge is discharged from the sludge discharge valve at the bottom of the reactor;

[0051] (3) Stop the water intake, and introduce 10% normal granular sludge of the effective volume of the reactor;

[0052] (4) Control the water intake to 100m 3 / h and strengthen the reflux cycle;

[0053](5) The ascending velocity in the control reactor is 4m / h;

[0054] (6) in the anaerobic reactor, add once every two days the polyaluminum chloride of 10mg / L;

[0055] (7) When the COD removal rate is 90%, the NiCl of 0.2mg / L 2 added to the reactor;

[0056] (8) Detect the gas output of methane, meet the normal operating conditions, and complete the treatment process.

Embodiment 3

[0058] (1) Connect a carbon dioxide detector to the gas outlet of the anaerobic reactor of the papermaking sewage treatment system to detect the amount of carbon dioxide produced;

[0059] (2) When the carbon dioxide flow is unstable and the pH value of the reactor outlet changes, the poisoned and rancid sludge is discharged from the sludge discharge valve at the bottom of the reactor;

[0060] (3) stop water intake, introduce 20% normal granular sludge of reactor effective volume;

[0061] (4) Control the water intake to 200m 3 / h and strengthen the reflux cycle;

[0062] (5) The ascending velocity in the control reactor is 6m / h;

[0063] (6) Add cationic polyacrylamide of 25mg / L and 25mg / L polyaluminum chloride every two days in the anaerobic reactor;

[0064] (7) When the COD removal rate is 95%, the FeCl of 0.5mg / L 2 and 0.5mg / L NiCl 2 added to the reactor;

[0065] (8) Detect the gas output of methane, meet the normal operating conditions, and complete the treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com