A simple and rapid method for producing phb/bacterial cellulose composites

A technology of bacterial cellulose and composite materials, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of single method, and achieve simple operation, low cost, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

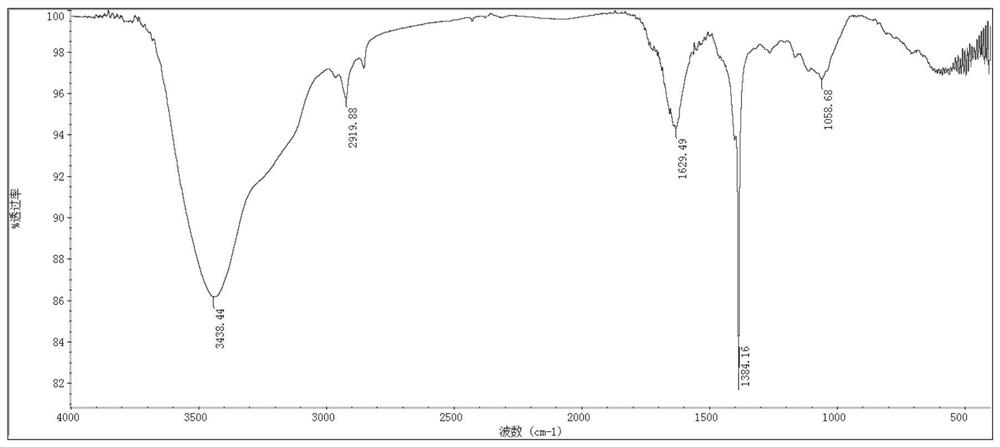

Embodiment 1

[0026] A simple and rapid method for producing PHB / bacterial cellulose composite material, comprising the following steps:

[0027] (1) Microbial culture: the Ralstonia eutropha H16 (DSN428) strain stored in the freeze-dried tube was activated in the seed medium, and after 24 hours of growth, with 5% of the inoculum, the obtained bacterial liquid was inoculated into the basal medium I Expanded culture to OD 600 If the value is 1, with the same inoculum amount, inoculate the bacterial liquid into the basal medium I again and repeat the expansion culture to its OD. 600 value is 1;

[0028] (2) the Gluconacetobacter xylinus ATCC700178 strain stored in the freeze-drying tube is activated in the basal medium II, after 48h of growth, the obtained bacterial liquid is inoculated into the basal medium II and expanded for 24h, and the inoculation amount is 5%, Take the bacterial liquid of the same inoculum amount and inoculate it into the basal medium II again for repeated expansion for...

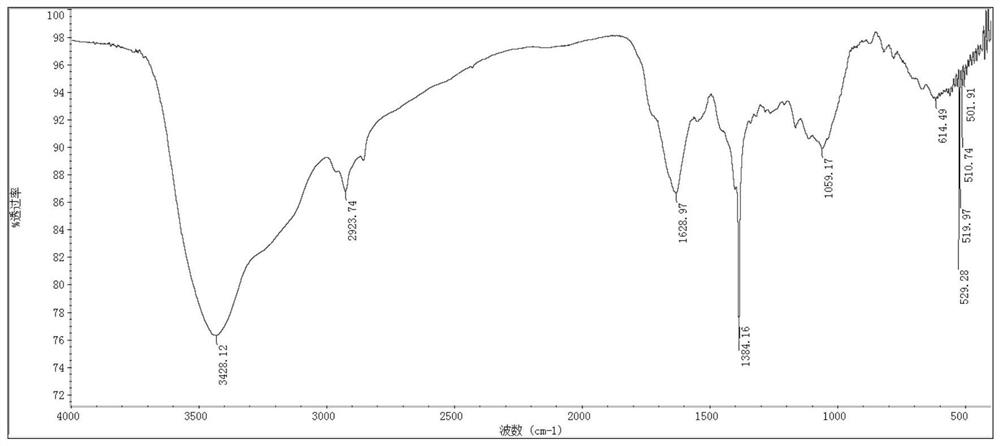

Embodiment 2

[0035] A simple and rapid method for producing PHB / bacterial cellulose composite material, comprising the following steps:

[0036] (1) Microbial culture: the Ralstonia eutropha H16 (DSM428) strain stored in the freeze-dried tube was activated in the seed medium, and after 24 hours of growth, the obtained bacterial liquid was inoculated into the basal medium I with a 5% inoculation amount Expanded culture to OD 600 If the value is 1, with the same inoculum amount, inoculate the bacterial liquid into the basal medium I again and repeat the expansion culture to its OD. 600 value is 1;

[0037] (2) the Gluconacetobacter xylinus ATCC700178 strain stored in the freeze-drying tube is activated in the basal medium II, after 48h of growth, the obtained bacterial liquid is inoculated into the basal medium II and expanded for 24h, and the inoculation amount is 5%, Take the bacterial liquid of the same inoculum amount and inoculate it into the basal medium II again for repeated expansi...

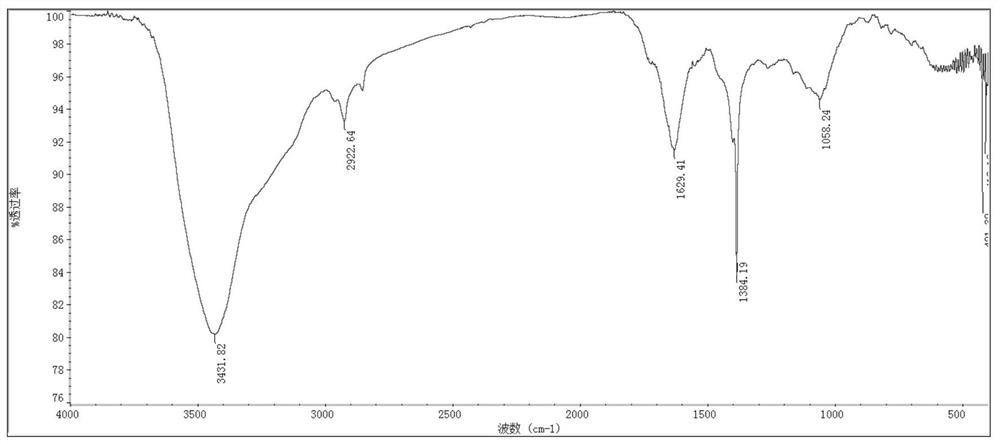

Embodiment 3

[0045] A simple and rapid method for producing PHB / bacterial cellulose composite material, comprising the following steps:

[0046] (1) Microbial culture: the Ralstonia eutropha H16 (DSM428) strain stored in the freeze-dried tube was activated in the seed medium, and after 24 hours of growth, the obtained bacterial liquid was inoculated into the basal medium I with a 5% inoculation amount Expanded culture to OD 600 If the value is 1, with the same inoculum amount, inoculate the bacterial liquid into the basal medium I again and repeat the expansion culture to its OD. 600 value is 1;

[0047] (2) the Gluconacetobacter xylinus ATCC700178 strain stored in the freeze-drying tube is activated in the basal medium II, after 48h of growth, the obtained bacterial liquid is inoculated into the basal medium II and expanded for 24h, and the inoculation amount is 5%, Take the bacterial liquid of the same inoculum amount and inoculate it into the basal medium II again for repeated expansi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com