Aging method and manufacturing method of aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitor and manufacturing method, applied in capacitor manufacturing, electrolytic capacitors, liquid electrolytic capacitors, etc., can solve the problems of high breakdown rate of aluminum electrolytic capacitors and poor repairing effect of oxide film, so as to improve repairing effect and improve repairing effect. effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

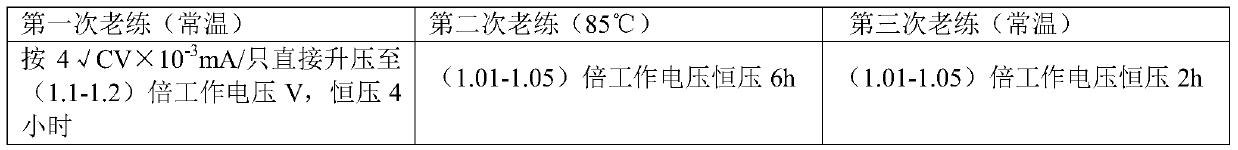

Embodiment 1

[0035]

[0036]

[0037] 1,000 products were put into production, and 4 were broken down. The pass rate: 99.6%. Record the parameters of 8 products:

[0038] serial number

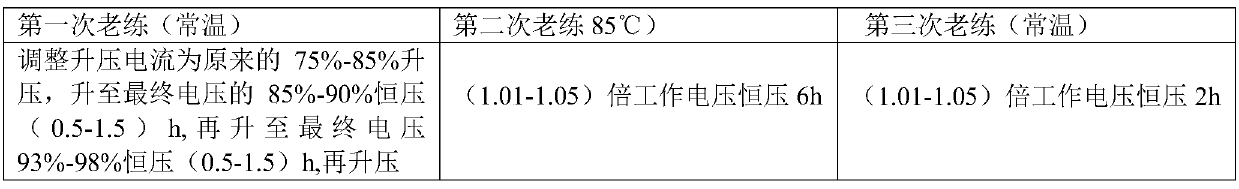

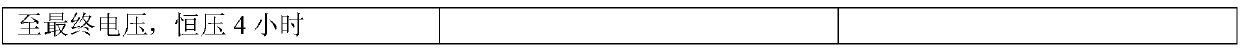

Embodiment 2

[0040]

[0041] 1,000 products were put into production, and 4 were broken down. The pass rate: 99.6%. Record the parameters of 8 products:

[0042] serial number

Embodiment 3

[0044]

[0045] 1,000 products were put into production, and 5 pieces were broken down. The experienced pass rate: 99.5%. Record the parameters of 8 products:

[0046] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com