Difunctional additive, electrolyte containing additive and lithium-ion battery

A technology of lithium-ion batteries and additives, applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of normal temperature cycle, low-temperature discharge and high-temperature storage performance, etc., to reduce the dissolution of transition metal ions, Effects of inhibition of reaction, improvement of cycle performance and high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] According to some embodiments of the present invention, the preparation method of the lithium-ion battery electrolyte includes the following steps:

[0055] S1: Add the electrolyte lithium salt into the purified organic solvent, stir to completely dissolve the lithium salt, and obtain a lithium salt solution;

[0056] S2: adding bifunctional additives, positive electrode film-forming additives and negative electrode film-forming additives to the above lithium salt solution, stirring, and standing to obtain a lithium-ion battery electrolyte.

[0057] Wherein, the purification of the organic solvent refers to the operation of removing impurities and water of the organic solvent, preferably through molecular sieve and activated carbon. Described molecular sieve can adopt type, type or type.

[0058] Preferably, the dissolution temperature of the electrolyte lithium salt in the organic solvent is 10-20°C.

[0059] Preferably, the standing time is 24-36h.

[0060] T...

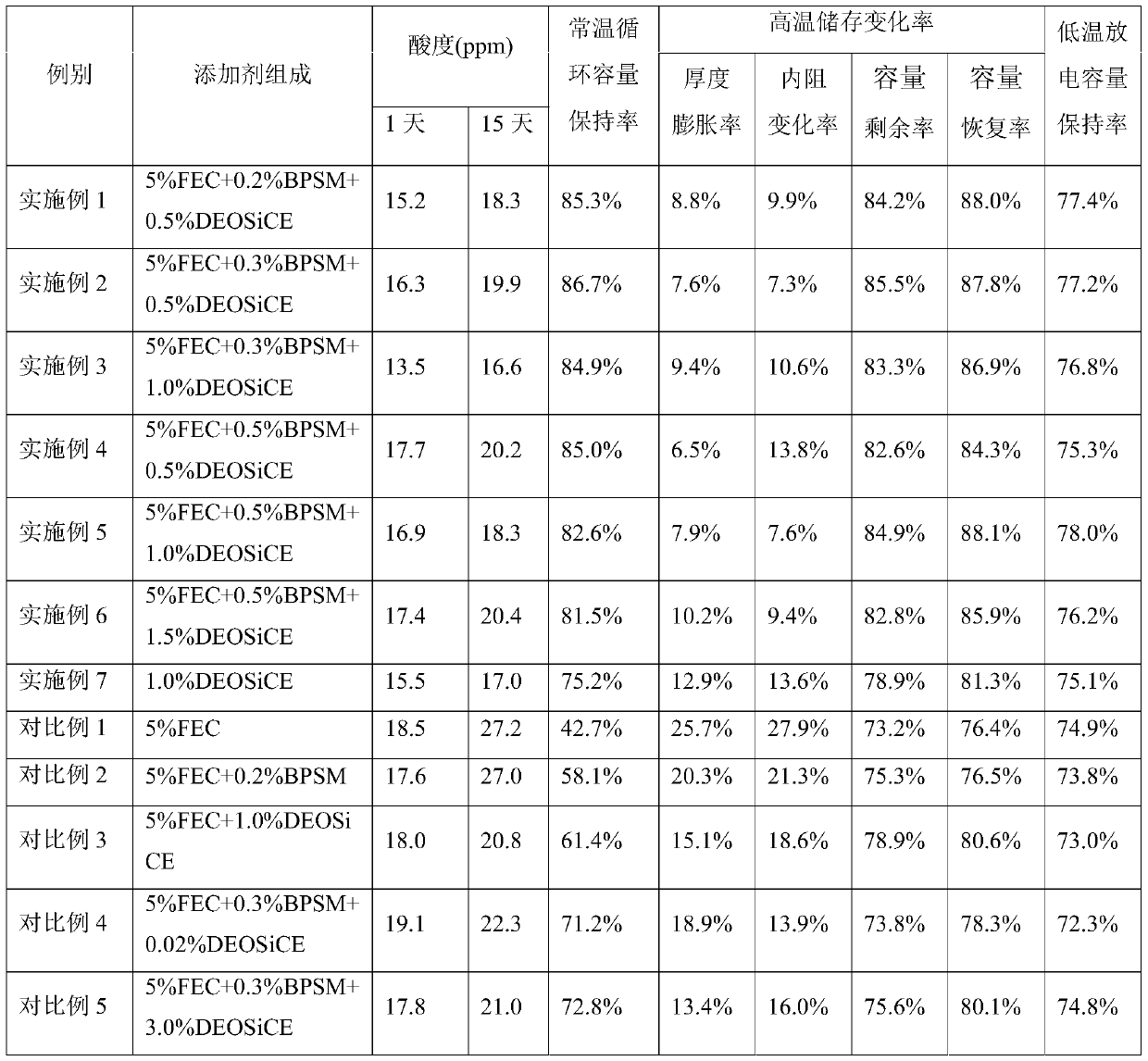

Embodiment 1

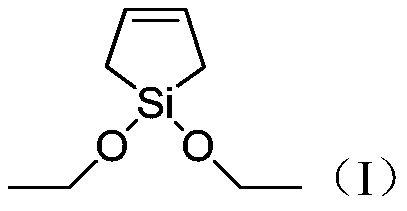

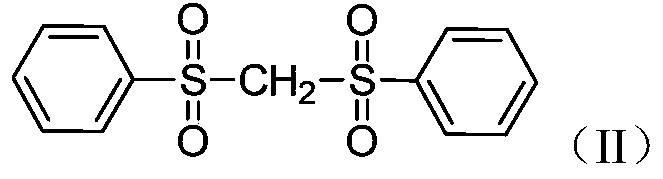

[0072] Ethyl methyl carbonate (EMC), ethylene carbonate (EC), diethyl carbonate (DEC) are purified, in the glove box that moisture is less than 10ppm, at 15 ℃, organic solvent is according to mass fraction EMC:EC:DEC= 7:5:3 mix well, add electrolyte lithium salt LiPF 6 Prepare a 1mol / L solution, stir and mix well, then add 5% fluoroethylene carbonate, 0.2% bisbenzenesulfonylmethane and 0.5% 1, 1-diethoxy-1-silacyclopent-3-ene, stirred and mixed evenly, and left to stand for 24 hours to prepare lithium-ion battery electrolyte.

Embodiment 2

[0074] Lithium-ion battery electrolyte: based on the sum of the mass of organic solvent and lithium salt as 100%, the addition of bisbenzenesulfonylmethane is 0.3%, 1,1-diethoxy-1-silacyclopenta- The addition of 3-ene is 0.5%, and others are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com