Cell module, and battery module and soft-package power battery applying cell module

A battery module and battery module technology, which is applied to battery components, secondary batteries, circuits, etc., can solve the problems of difficult assembly of module waterways, poor fluid flow, and poor thermal management of battery modules, etc. problem, to achieve good effect, excellent heating and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

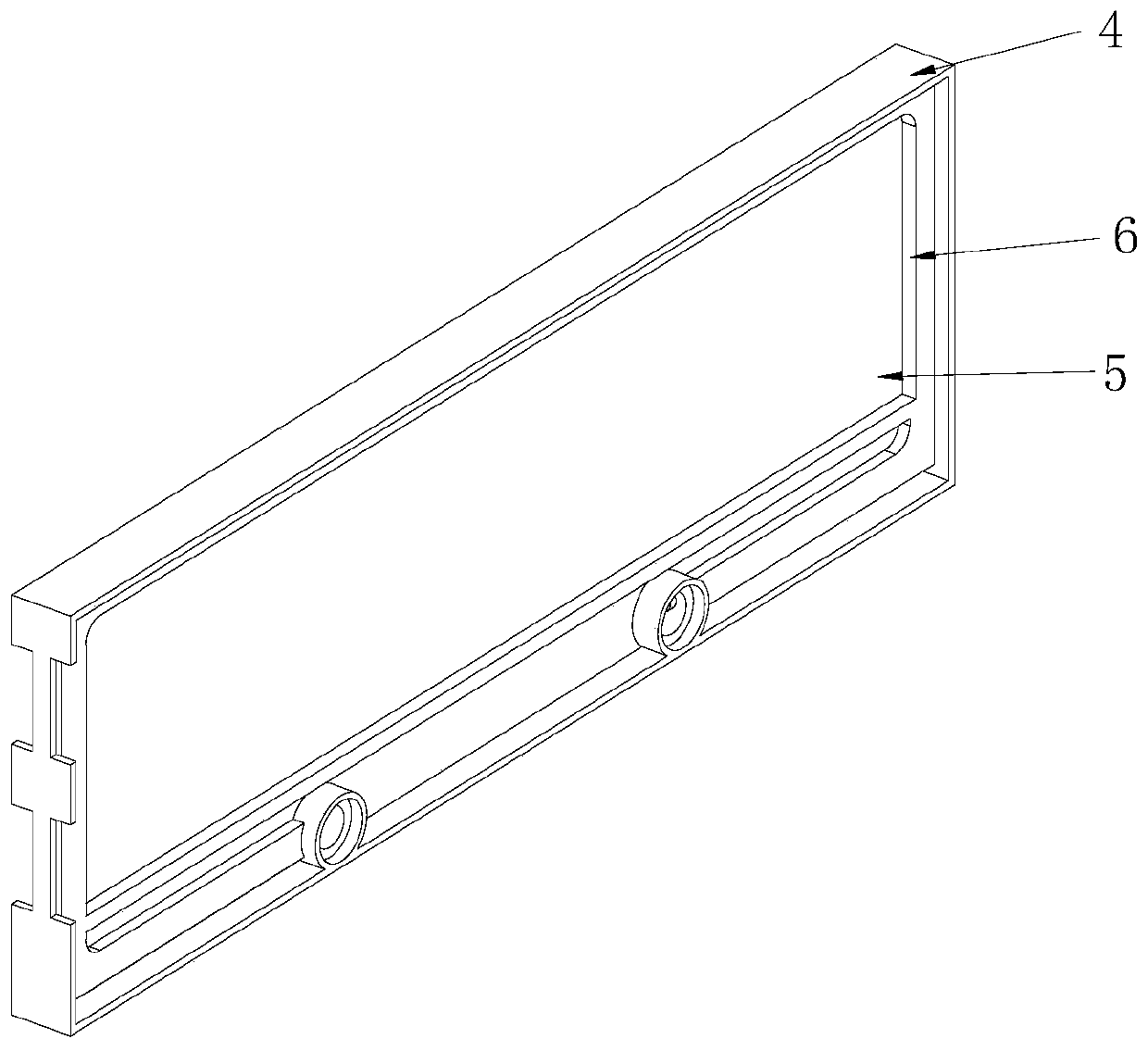

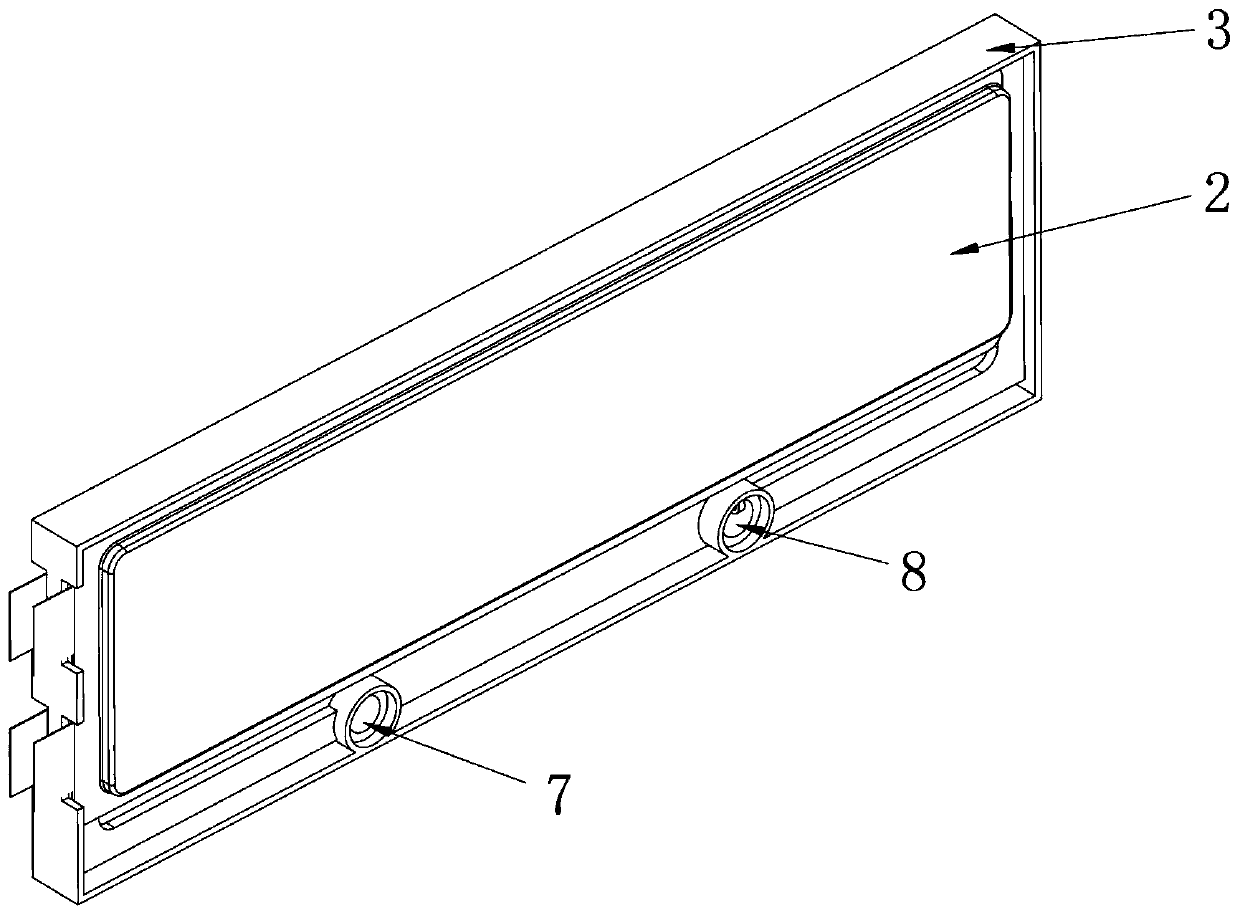

[0035] Such as Figure 1~3 The cell module 1 shown includes a cell 2 and a cell support 3; the cell support 3 includes a module frame 4 made of plastic, and the module frame 4 includes a frame body with a rectangular outer contour. A hollow hole 5 with a rectangular cross-sectional profile is provided in the center, and the hollow hole 5 runs through the entire module frame 4 along the thickness direction of the module frame 4; in the frame body, the hollow hole 5 is formed around the circumference of the heat sink for fixing the battery core 2 The fixed edge 6 of the position; the lower side of the frame body is provided with a water inlet 7 and a water outlet 8, and the water inlet 7 and the water outlet 8 also run through the entire module frame 4 along the thickness direction of the module frame 4, and the water inlet 7 and the water outlet The water port 8 is isolated from the empty hole 5 , and the liquid flowing in the water inlet 7 and the water outlet 8 cannot flow to...

Embodiment 2

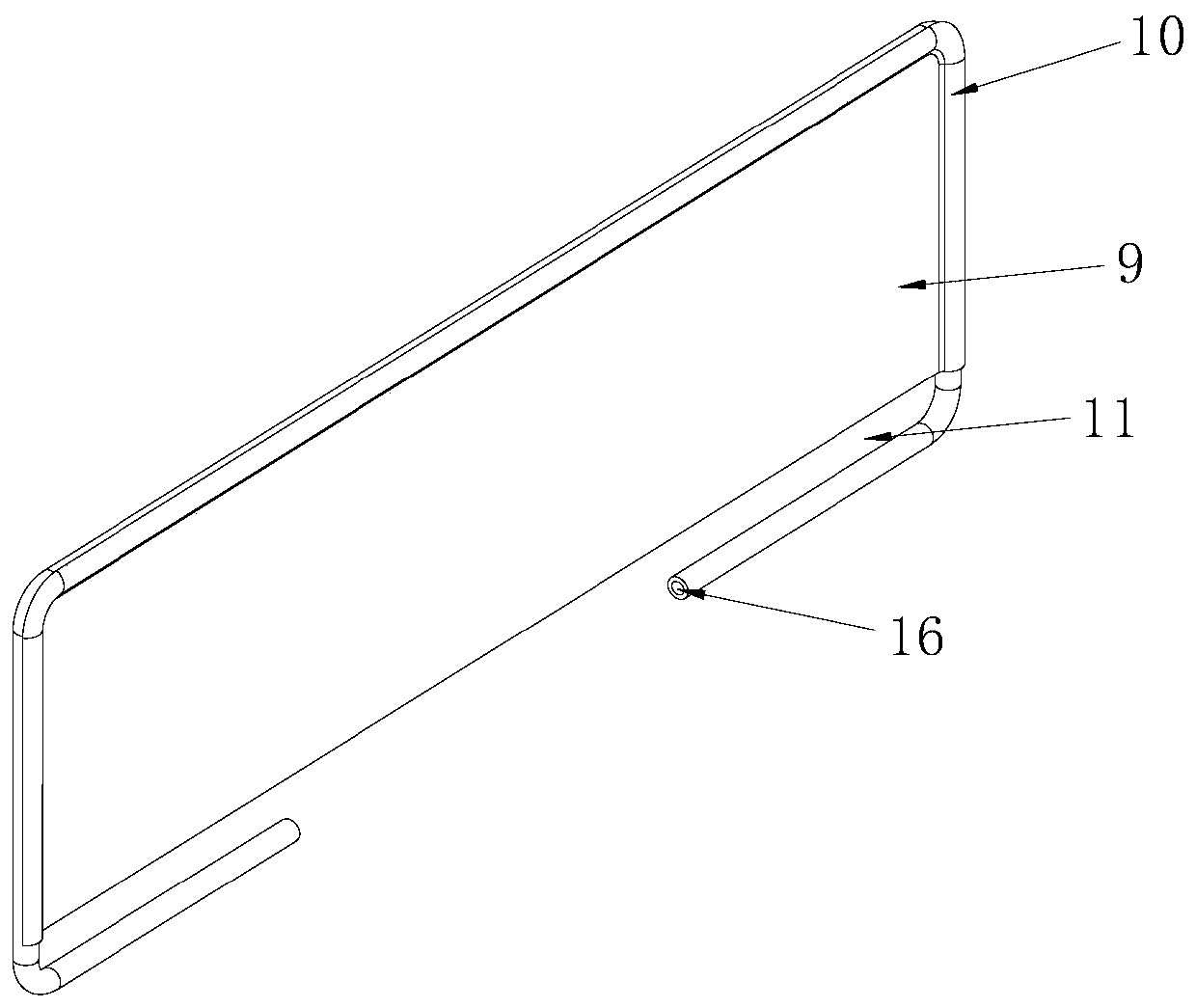

[0041] Such as Figure 4~6The shown battery module includes an intermediate bracket 12, the outer contour shape of the intermediate bracket 12 is similar to the outer contour shape of the cell bracket 3, the bottom of the intermediate bracket 12 is provided with a main water inlet 13 and a main water outlet 14, the middle bracket The lower side of 12 is provided with a water inlet channel 15 communicating with the main water inlet 13 and a water outlet channel (not shown in the figure) communicating with the main water outlet 14 . A plurality of cell modules 1 are evenly arranged on both sides of the middle support 12 . The cell modules 1 adopt the design described in Embodiment 1, and the number of cell modules 1 can be determined according to actual production requirements.

[0042] The battery modules 1 arranged on both sides of the middle support 12, the water inlets 7 of the adjacent battery modules 1 are connected in sequence and communicate with the water inlet channel ...

Embodiment 3

[0045] Such as Figure 7 , 8 The soft pack power battery shown includes an upper case 19 and a lower case 20 that are covered with each other. The upper case 19 and the lower case 20 are covered to form a cavity 21 with front and rear openings, and the cavity 21 is installed There is a battery module as described in Example 2. An initial water inlet 22 communicating with the main water inlet 13 and an initial water outlet 23 communicating with the main water outlet 14 are provided on the lower housing 20, so that the soft pack power battery can be placed in the lower box and fixed directly with the lower box. The waterway connection simplifies the assembly and application of the pouch power battery and facilitates maintenance.

[0046] In the third embodiment, the cell module 1 is equipped with a confluence acquisition component 24 for realizing high-voltage connection and voltage and temperature signal acquisition, and a module cover plate 25 is installed on the outside of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap