Foamed aluminum composite sheet material production process and sheet material

A composite board and foam aluminum board technology, which is applied in wood processing appliances, layered products, manufacturing tools, etc., can solve the problems of affecting the bonding strength of composite materials, increase the density of composite boards, and low production efficiency, and achieve environmental protection and convenient construction. , the stress distribution is uniform, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

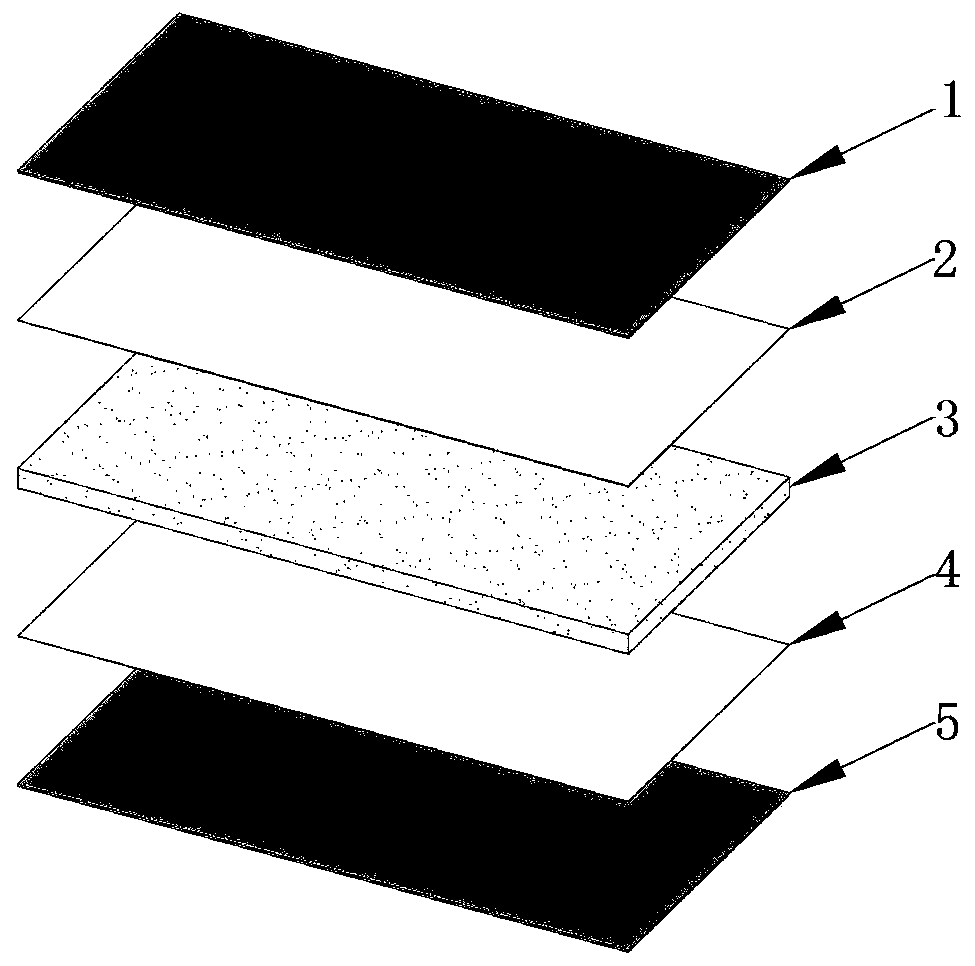

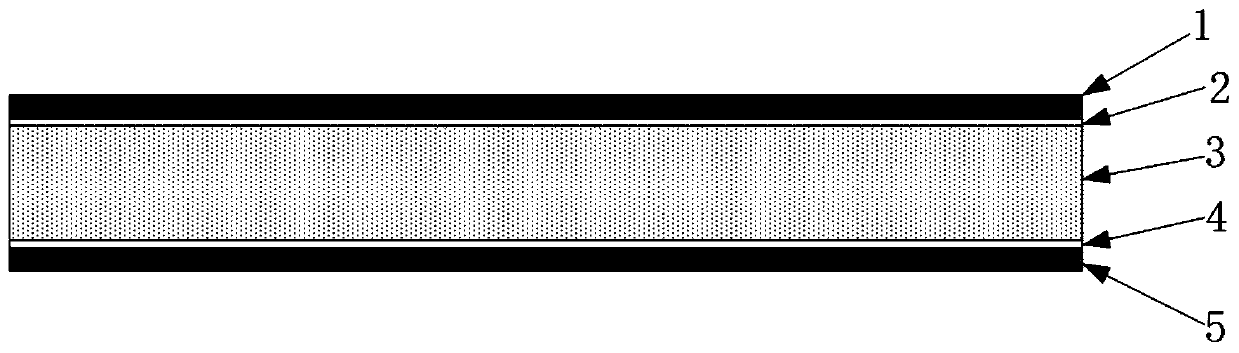

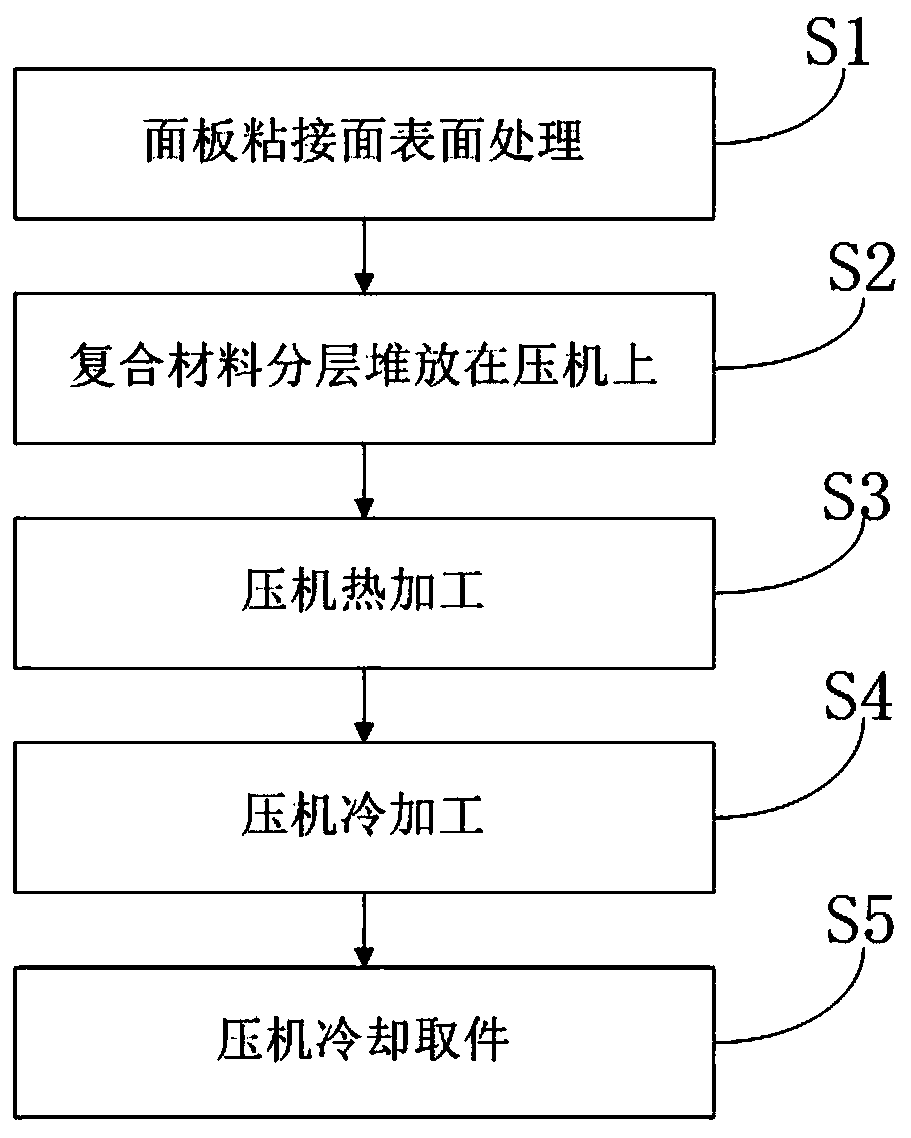

[0038] Such as figure 1 and figure 2 As shown, this embodiment provides a flame-retardant and heat-insulating aluminum foam composite board, including a foamed aluminum board 3 and panels arranged on both sides of the foamed aluminum board 3, and the two side panels are a first panel 1 and a second panel 5 respectively. The panel layer is made of wood or aluminum, copper, steel and other metal plates. Aluminum foam is a kind of porous metal with low density, high strength and low thermal conductivity, which makes this composite board have good sound insulation effect and flame retardant and heat insulation performance. The overall thickness of the aluminum foam composite board is between 12mm and 50mm, which can be applied to building and home decoration materials, which solves the shortcomings of a single board, can greatly improve the safety and comfort of the home environment, and has good application value and promotion prospect.

[0039] The foamed aluminum plate 3 and...

Embodiment 2

[0041] In this embodiment, on the basis of the above-mentioned embodiments, the adhesive used in the adhesive film is a curable adhesive resin, and the raw material formula of the curable adhesive resin includes the following components by weight percentage: 35% to 45% polyethylene, 35%-45% polyethylene graft polymer, 15-25% elastomer. Wherein, polyethylene is one or any combination of low-density polyethylene, linear low-density polyethylene, and high-density polyethylene. The polyethylene graft polymer is one or any combination of maleic anhydride grafted polyethylene and acrylic acid grafted polyethylene. The elastomer is one or any combination of SIS, SEBS, SBR, TPU, NBR. The density of the adhesive film is 0.92g / cm3-0.95g / cm3, which is lower than the density of 1.2g / cm3-1.4g / cm3 of commonly used two-component epoxy resin glue, and the composite board produced is lighter.

[0042]There are physical stress and chemical stress between the adhesive film and the bonding surf...

Embodiment 3

[0044] In this embodiment, on the basis of the above-mentioned embodiments, the adhesive film includes a foamed aluminum adhesive layer and a board adhesive layer, which are respectively used for laminating the foamed aluminum plate 3 and the panel. In order to meet the overall thickness requirement of the composite board, the thickness of the foamed aluminum board 3 is between 10 mm and 30 mm, and the thickness of the panel is between 1 mm and 10 mm. The thickness of the aluminum foam adhesive layer is between 0.15mm and 0.25mm, and the thickness of the plate adhesive layer is between 0.1mm and 0.15mm. The thickness of the aluminum foam adhesive layer and the panel adhesive layer are different, which can meet the different bonding requirements on both sides. , wherein the contact area between the foamed aluminum adhesive layer and the foamed aluminum plate 3 is smaller than the contact area between the plate adhesive layer and the panel, so the thickness of the foamed aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com