A kind of preparation method of stannous sulfide

A technology of stannous sulfide and tin powder, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of difficult cleaning and removal, large investment, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 119 grams of 200 mesh 2N metal tin powder and 32 grams of sublimated sulfur powder in the mixer according to the molar ratio of tin powder (99%, particle size <150μm) to sublimation sulfur powder of 1:1. Mix for 1h;

[0029] (2) Raise the temperature of the reaction furnace to 650°C, and replace the air in the furnace with nitrogen for 30 minutes;

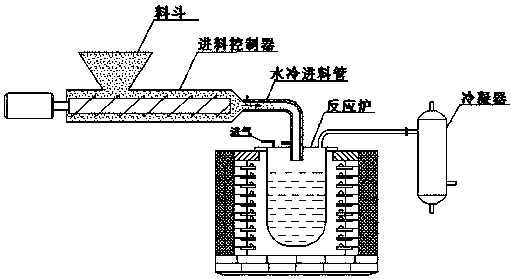

[0030] (3) Put the mixed powder in the figure 1 In the hopper, the tin and sulfur powder react rapidly in a nitrogen atmosphere at 650 °C to form stannous sulfide, and are fed into the reaction furnace at a constant speed through the feeding controller. After the feeding is completed, the temperature in the furnace is maintained at 650 °C. 2h, make the excess sulfur evaporate and enter the condenser to condense and collect;

[0031] (4) Natural cooling of stannous sulfide in the furnace after impurity removal;

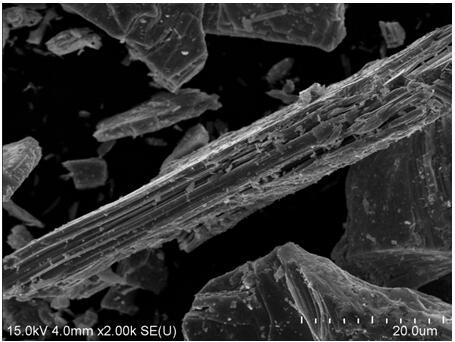

[0032] (5) After the furnace temperature is cooled to room temperature, open the furnace cover to tak...

Embodiment 2

[0034] (1) According to the molar ratio of tin powder (99.9%, particle size < 150μm) and sublimation sulfur powder as 1:1.5, weigh 119 grams of 200-mesh 3N metal tin powder and 48 grams of sublimated sulfur powder in the mixer. Mix for 1h;

[0035] (2) Raise the temperature of the reaction furnace to 750℃, and replace the air in the furnace with nitrogen for 30min;

[0036] (3) Put the mixed powder in the figure 1 In the hopper, it is added to the reaction furnace at a constant speed through the feeding controller, and the powder and sulfur powder react rapidly in a nitrogen atmosphere at 750 ° C to form stannous sulfide; After the sulfur evaporates, it enters the condenser to condense and collect;

[0037] (4) Natural cooling of stannous sulfide in the furnace after impurity removal;

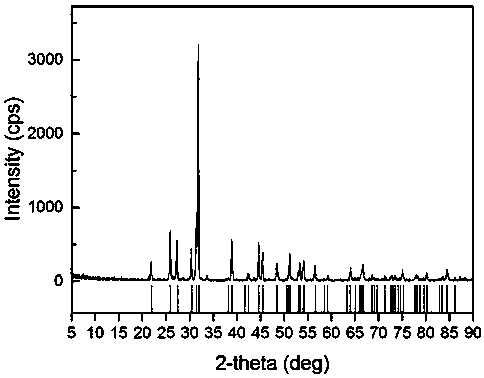

[0038] (5) After the furnace temperature is cooled to room temperature, open the furnace cover to take out the sample, and the preparation of the stannous sulfide sample is completed; the pu...

Embodiment 3

[0040] (1) According to the molar ratio of tin powder (99.99%, particle size < 150μm) and sublimation sulfur powder of 1:2, weigh 119 grams of 200-mesh 4N metal tin powder and 64 grams of sublimated sulfur powder in the mixer. Mix for 1h;

[0041] (2) Raise the temperature of the reaction furnace to 800℃, and replace the air in the furnace with argon for 30min;

[0042] (3) Put the mixed powder in the figure 1 In the hopper, and fed into the reaction furnace at a constant speed through the feeding controller, the tin powder and the sulfur powder reacted rapidly in an argon atmosphere at 800 ° C to form stannous sulfide. After the feeding, the furnace temperature was maintained at 800 ° C for 2 hours. After the excess sulfur is evaporated, it enters the condenser to condense and collect;

[0043] (4) Naturally cool stannous sulfide in the furnace after removing elemental sulfur;

[0044] (5) After the furnace temperature is cooled to room temperature, open the furnace cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com