Antibacterial photo-degradation composite film as well as preparation method thereof and application thereof

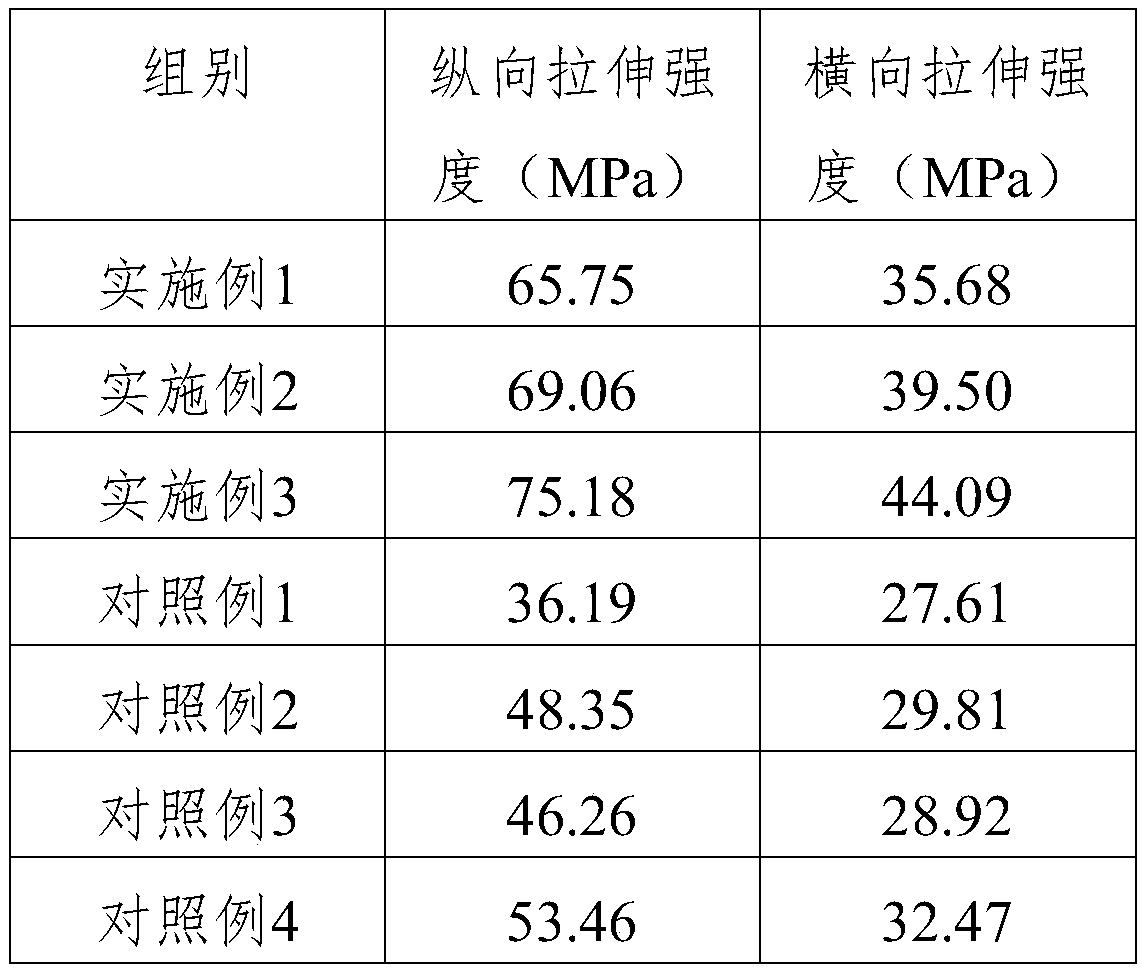

A composite film and photodegradation technology, applied in the field of composite film, can solve the problems of poor mechanical performance, antibacterial performance and photodegradation performance, and achieve the effect of increasing photodegradation rate, improving comprehensive performance and excellent mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Antibacterial photodegradable composite film

[0044] Above-mentioned composite film is prepared by comprising following raw materials:

[0045] Modified Nano TiO 2 20 parts, 2.5 parts of potassium sorbate, 10 parts of calcium propionate, 15 parts of Span80, 105 parts of LLDPE and 16 parts of HDPE.

[0046] 2. Preparation method

[0047] Above-mentioned preparation method comprises the steps:

[0048](a) Modified nano-TiO 2 , Potassium sorbate, Calcium propionate, Span80 and LLDPE were placed in a high mixer and mixed for 30 minutes, left to stand for 20 hours, and then obtained nano-modified composite masterbatch by twin-screw extrusion and granulation; the granulation molding temperature was 150°C ;

[0049] (b) Mixing the nano-modified composite masterbatch with HDPE, and blow molding it with an extrusion blown film system to obtain an antibacterial and photodegradable composite film; wherein, the blow molding temperature is 190°C; the die temperature is 175°...

Embodiment 2

[0051] 1. Antibacterial photodegradable composite film

[0052] Above-mentioned composite film is prepared by comprising following raw materials:

[0053] Modified Nano TiO 2 2 parts, 10 parts of potassium sorbate, 2.5 parts of calcium propionate, 5 parts of Span80, 95 parts of LLDPE and 10 parts of HDPE.

[0054] 2. Preparation method

[0055] Above-mentioned preparation method comprises the steps:

[0056] (a) Modified nano-TiO 2 , Potassium sorbate, Calcium propionate, Span80 and LLDPE were placed in a high mixer and mixed for 30 minutes, left to stand for 28 hours, and then obtained nano-modified composite masterbatch by twin-screw extrusion and granulation; the granulation molding temperature was 170°C ;

[0057] (b) Mix the nano-modified composite masterbatch with HDPE, and blow mold it with an extrusion blown film system to obtain an antibacterial and photodegradable composite film; wherein, the blow molding temperature is 170°C; the die temperature is 185°C.

Embodiment 3

[0059] 1. Antibacterial photodegradable composite film

[0060] Above-mentioned composite film is prepared by comprising following raw materials:

[0061] Modified Nano TiO 2 10 parts, potassium sorbate 5 parts, calcium propionate 5 parts, Span80 10 parts, LLDPE 100 parts and HDPE 13 parts.

[0062] 2. Preparation method

[0063] Above-mentioned preparation method comprises the steps:

[0064] (a) Modified nano-TiO 2 , Potassium sorbate, Calcium propionate, Span80 and LLDPE were placed in a high mixer and mixed for 30 minutes, left to stand for 24 hours, and then obtained nano-modified composite masterbatch by twin-screw extrusion and granulation; the granulation molding temperature was 160°C ;

[0065] (b) Mixing the nano-modified composite masterbatch with HDPE, and blow molding it with an extrusion blown film system to obtain an antibacterial and photodegradable composite film; wherein, the blow molding temperature is 180°C; the die temperature is 180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com