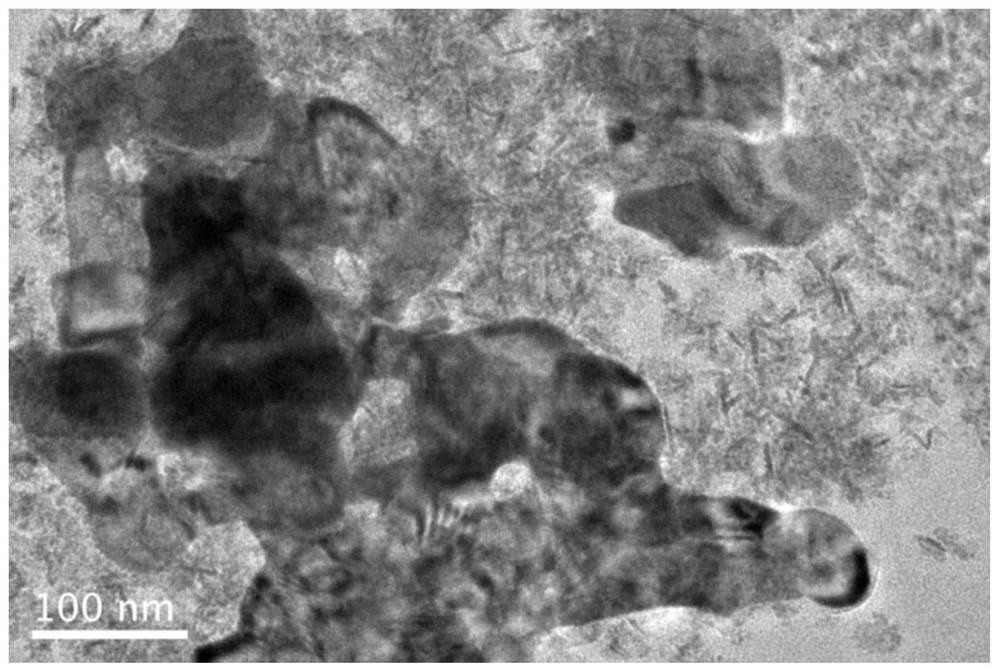

Preparation method of bismuth tungstate and cadmium sulfide hybrid nanocrystals

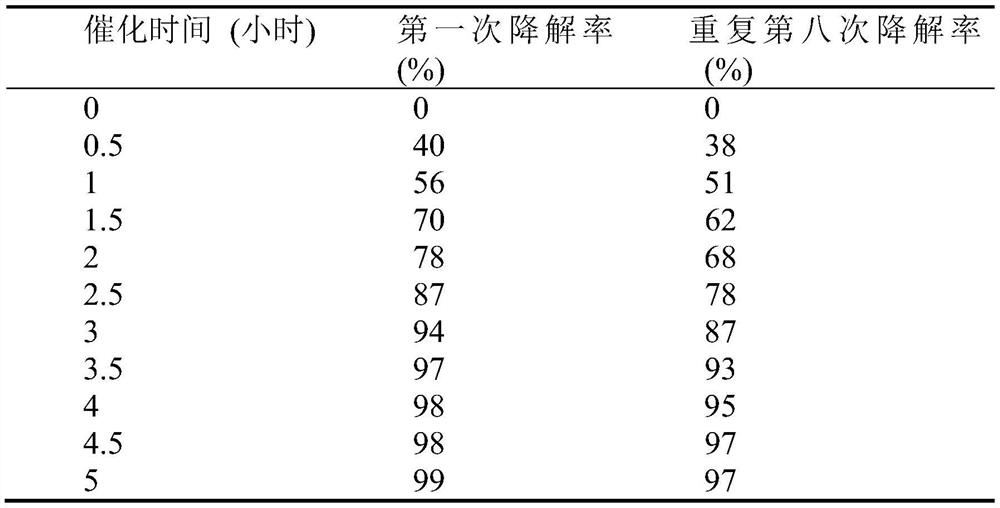

A nanocrystalline, bismuth tungstate technology, applied in catalyst activation/preparation, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the difficulty of obtaining block copolymers and limit the wide range of polymer vesicles Application and other issues, to achieve the effect of improving photodegradation rate and repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Formation of polymersomes containing soluble salts:

[0028] At room temperature, the aqueous solution of the soluble bismuth nitrate salt of 25 grams of 1% mass concentration is added dropwise to the polystyrene block polyvinyl alcohol polymer (polymerization of polyvinyl alcohol) of 100 grams of 0.1% mass concentration according to the fixed rate of 0.25 g / min. Unit number is 100, polystyrene unit number is 200) dimethyl formamide is in the solution of solvent, then pulverizes under high-speed shearing machine; After 5 minutes, the temperature of the mixed solution is controlled at 10° C., and polymersomes containing soluble bismuth nitrate salt can be obtained.

[0029] According to the above method and ratio, soluble sodium tungstate, soluble cadmium nitrate and soluble sodium sulfide are used to replace soluble bismuth nitrate salt respectively, and finally four polymers containing soluble tungstate, soluble cadmium salt and soluble sulfide are formed respectiv...

Embodiment 2

[0035] (1) Formation of polymer vesicles containing soluble salts:

[0036]At room temperature, the aqueous solution of 25 grams of 3% mass concentration of soluble bismuth nitrate salt is added dropwise to 0.3% mass concentration according to a fixed rate of 0.25 g / min, polystyrene block polyvinyl alcohol polymer (the number of polymerized units of polyvinyl alcohol be 200, polystyrene unit number is 500) dimethyl formamide is in the solution 100 grams of solvent, pulverizes under high-speed shearing machine then; After 5 minutes, the temperature of the mixed solution is controlled at 10° C., and the polymer vesicles containing soluble bismuth nitrate salt can be obtained. According to the above method and formula, the soluble bismuth nitrate salt is replaced with soluble sodium tungstate salt, soluble cadmium sulfate salt and soluble sodium sulfide salt, respectively, and finally four kinds of salts containing soluble tungstate, soluble cadmium salt and soluble sulfide are f...

Embodiment 3

[0042] (1) Formation of polymer vesicles containing soluble salts:

[0043] At room temperature, the aqueous solution of 25 grams of 2% mass concentration of soluble bismuth nitrate salt is added dropwise to 0.2% mass concentration according to a fixed rate of 0.25 g / min, polymethyl methacrylate block polyvinyl alcohol polymer (polyvinyl alcohol Polymerized unit number is 150, polystyrene unit number is 400) dimethyl formamide is in the solution 100 grams of solvent, pulverizes under high-speed shearing machine then; The fixing time is 5 minutes, and the temperature of the mixed solution is controlled at 10° C. to obtain polymersomes containing soluble bismuth nitrate salt. According to the above method and formula, the soluble bismuth nitrate salt is replaced with soluble sodium tungstate salt, soluble cadmium sulfate salt and soluble sodium sulfide salt, respectively, and finally four kinds of salts containing soluble tungstate, soluble cadmium salt and soluble sulfide are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com