A kind of photodegradable polypropylene material and preparation method thereof

A polypropylene material and photodegradation technology, applied in the field of polymer materials, can solve the problems of long degradation cycle, difficult application, and easy environmental hazards, etc., and achieve the goal of increasing the photodegradation rate, enhancing the scope and ability, and promoting the degradation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of photodegradation agent ferric eleostearate provided by the invention

[0032] Stir tung oil, ethanol and sodium hydroxide solution in an oil pan at a temperature of 70 °C; then use dilute acid to adjust the pH of the mixture to 2, then add sodium hydroxide solution, ferric chloride hexahydrate and petroleum ether to the oil pan for 70 °C. ℃ reaction, after the solution is layered and the upper layer solution is red, a small amount of petroleum ether is added for liquid separation, the upper layer liquid is separated and put into molecular sieves to remove moisture, and then the petroleum ether is evaporated and removed by rotary evaporation to obtain the photodegradation agent of the present invention. Iron acid.

Embodiment 2

[0034] Preparation of conventional photodegradants iron stearate and iron oleate

[0035] React stearic acid and 30% sodium hydroxide in an oil pan at 70°C, then add ferric chloride and cyclohexane to keep the temperature and continue the reaction. After the solution is layered and the upper layer solution is red, add a small amount of cyclohexane to separate the liquid. , take out the upper layer liquid and put it into molecular sieve to remove water, and then rotary steam to evaporate cyclohexane to obtain iron stearate.

[0036] React oleic acid and 30% sodium hydroxide in an oil pan at 90°C, then add ferric chloride and petroleum ether to keep the temperature and continue the reaction. After the solution is layered and the upper layer solution is red, add a small amount of petroleum ether to separate the liquid, and take out the upper layer. The liquid is put into molecular sieve to remove water, and then the petroleum ether is evaporated by rotary evaporation to obtain ir...

experiment example 1

[0038] Absorbance test of photodegradants

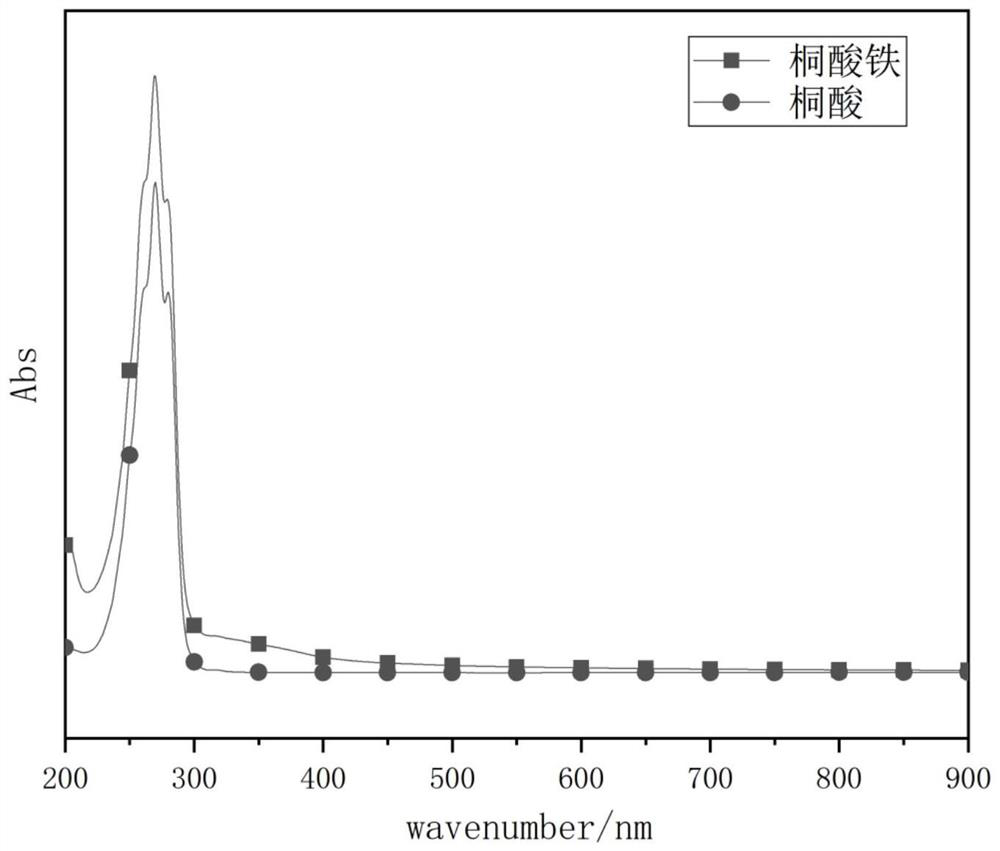

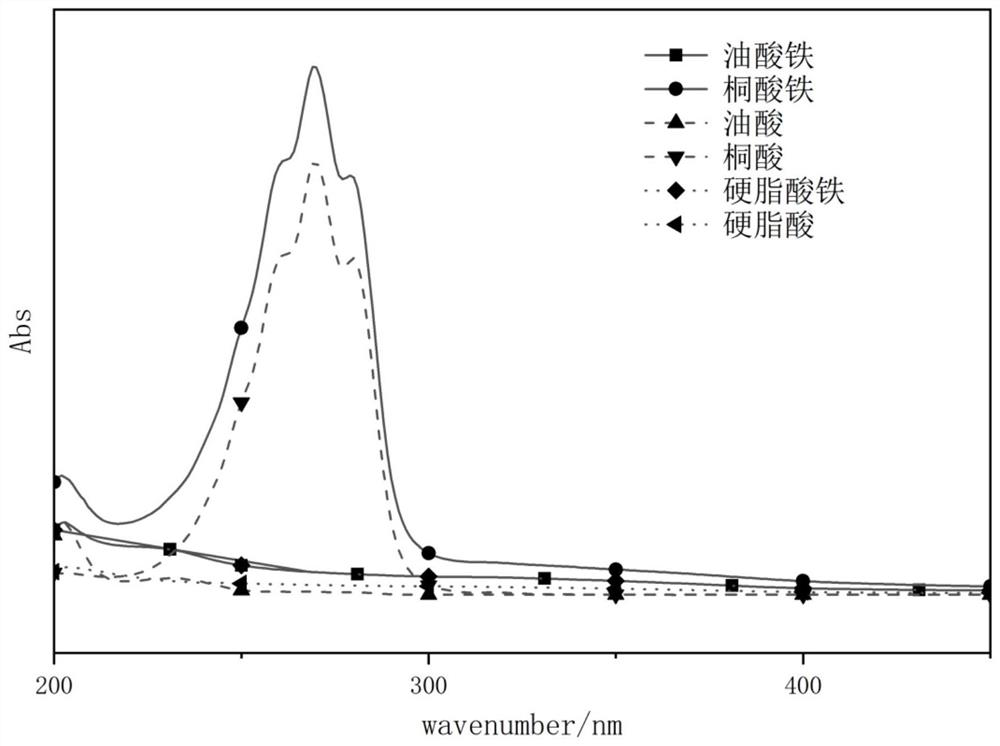

[0039] Take a small amount of ferric oleate, ferric eleostearate, ferric stearate, oleic acid, eleostearic acid and stearic acid, respectively, dissolve them in cyclohexane, and then use a volumetric flask to make a system concentration of 0.1mol / L, and then use a volumetric flask. Dilute the solution by 10 times and analyze it with an ultraviolet-visible light analyzer to obtain an ultraviolet-visible absorption spectrum such as Figure 1 to Figure 2 shown.

[0040] Depend on figure 1It can be seen that both eleostearic acid and ferric eleostearate have very obvious absorption peaks at the ultraviolet light of 200-300 nm wavelength, and after synthesizing ferric eleostearate, ferric eleostearate has a wider wavelength range of ultraviolet light absorption spectrum than that of eleostearic acid. The absorption range of ferric eleostearate for ultraviolet light can basically cover the wavelength range of ultraviolet light and reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com