A plastic waste degradation treatment agent and preparation method thereof

A plastic waste and treatment agent technology, which is applied in the direction of protective devices against harmful chemicals, etc., can solve problems such as uneconomical, difficult to promote, and difficult to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

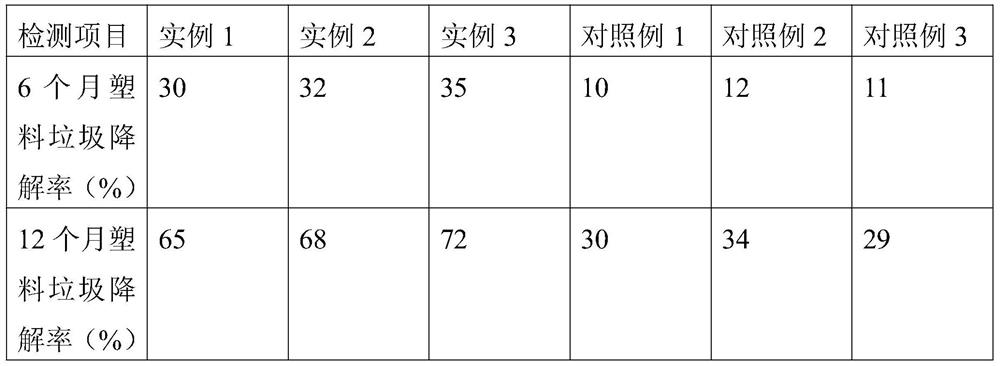

Examples

example 1

[0032]Nanocellulose and deionized water are mixed in a mass ratio of 1:10 to obtain a nanocellulose suspension, and then the nanocellulose suspension and sodium silicate are mixed in a mass ratio of 10:3 to obtain a mixed solution, with a concentration of After adjusting the pH of the mixed solution to 4 with 1mol / L hydrochloric acid, stir and react for 2 hours, then filter and separate to obtain the filter residue; mix the filter residue obtained above with deionized water at a mass ratio of 1:5, put it into a high-temperature reactor, and heat up to 250°C , stirred and reacted for 1 hour, filtered and separated to obtain a filter cake, and dried to obtain a degradation agent matrix; the mussel mucin was mixed with a 0.9% sodium chloride solution in a mass ratio of 1:8 to obtain a mussel mucin liquid, Mix the degradant matrix obtained above with the mussel mucin liquid at a mass ratio of 1:10 to obtain a mixture; move the mixture obtained above into a reactor, and add a concen...

example 2

[0034] Nanocellulose and deionized water are mixed in a mass ratio of 1:10 to obtain a nanocellulose suspension, and then the nanocellulose suspension and sodium silicate are mixed in a mass ratio of 10:3 to obtain a mixed solution, with a concentration of After adjusting the pH of the mixed solution to 5 with 1mol / L hydrochloric acid, stir and react for 3 hours, filter and separate to obtain the filter residue; mix the filter residue obtained above with deionized water at a mass ratio of 1:5, put it into a high-temperature reactor, and heat up to 300°C , stirred and reacted for 2 hours, filtered and separated to obtain a filter cake, and dried to obtain a degradation agent matrix; the mussel mucin was mixed with a 0.9% sodium chloride solution in a mass ratio of 1:8 to obtain a mussel mucin liquid, Mix the degradant matrix obtained above with the mussel mucin liquid at a mass ratio of 1:10 to obtain a mixture; move the mixture obtained above into a reactor, and add a concentra...

example 3

[0036] Nanocellulose and deionized water are mixed in a mass ratio of 1:10 to obtain a nanocellulose suspension, and then the nanocellulose suspension and sodium silicate are mixed in a mass ratio of 10:3 to obtain a mixed solution, with a concentration of After adjusting the pH of the mixed solution to 5 with 1mol / L hydrochloric acid, stir and react for 3 hours, filter and separate to obtain the filter residue; mix the filter residue obtained above with deionized water at a mass ratio of 1:5, put it into a high-temperature reactor, and heat up to 350°C , stirred and reacted for 2 hours, filtered and separated to obtain a filter cake, and dried to obtain a degradation agent matrix; the mussel mucin was mixed with a 0.9% sodium chloride solution in a mass ratio of 1:8 to obtain a mussel mucin liquid, Mix the degradant matrix obtained above with the mussel mucin liquid at a mass ratio of 1:10 to obtain a mixture; move the mixture obtained above into a reactor, and add a concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com