A kind of water-based damping coating and its application in automobile field

A damping coating, water-based technology, applied in polyurea/polyurethane coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems of chemical resistance decline and poor paint film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

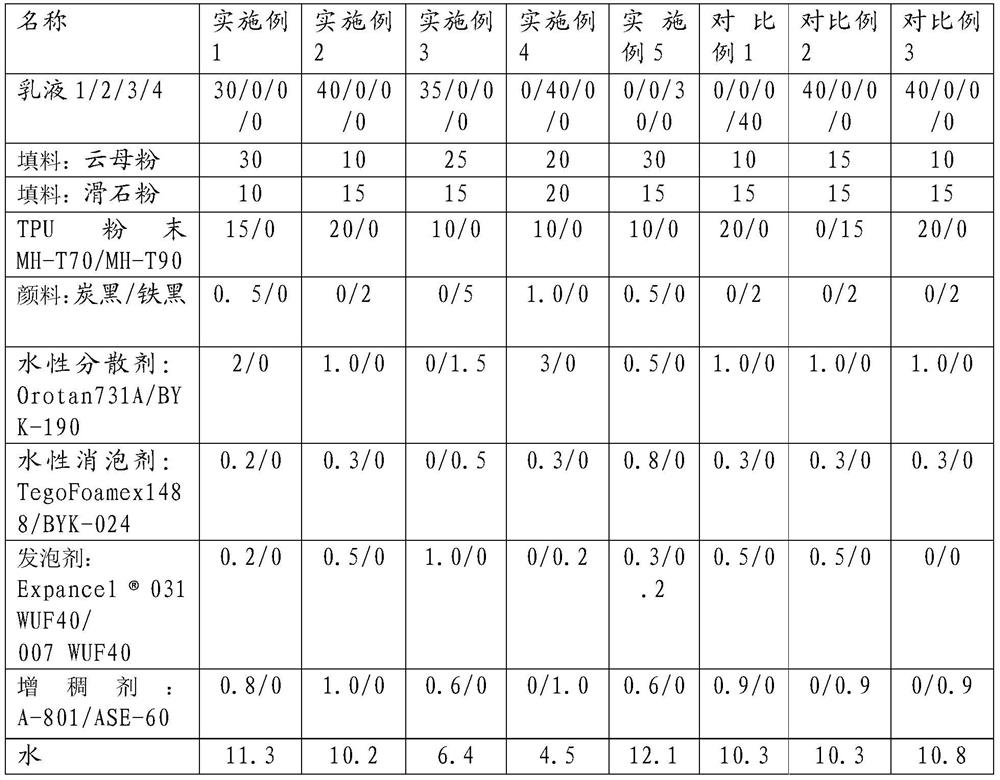

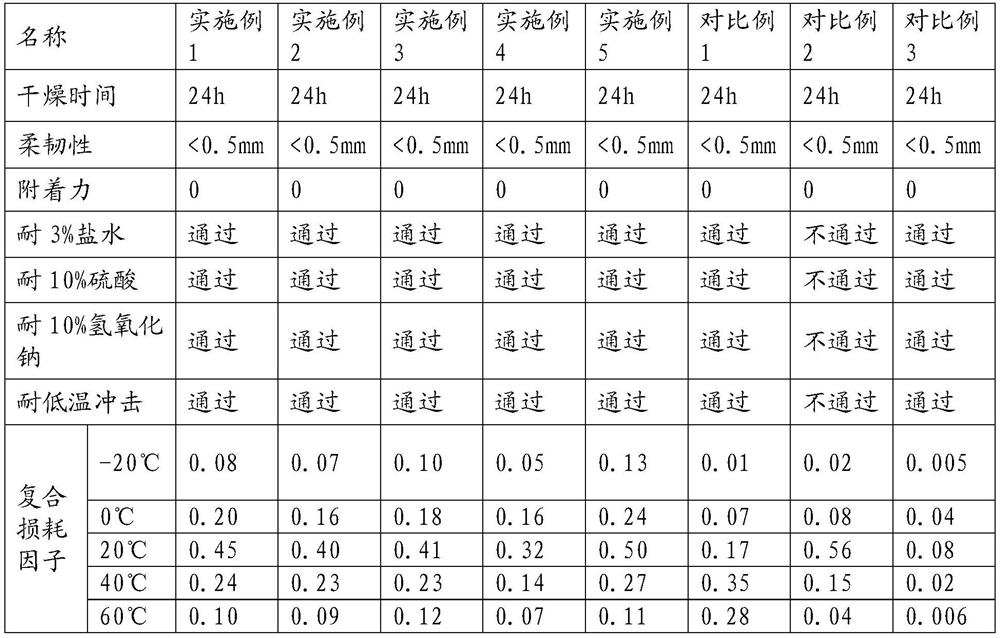

Embodiment 1

[0050] Add 30g of emulsion 1 into the paint mixing tank, adjust the speed of the disperser to 600r / min, add 2g of Orotan731A and 0.1g of Tego Foamex1488 in turn and stir for 5min. Add 0.2g of Add 031WUF40, 30g mica powder, 10g talc powder, 15gMH-T70, 0.5g carbon black in sequence, adjust the speed of the disperser to 1500r / min, and stir for 30min.

[0051] Reduce the speed of the disperser to 800r / min, add 0.8gA-801, 11.3g water and 0.1g TegoFoamex1488, stir for 15min and then discharge.

Embodiment 2

[0053] Add 40g of emulsion 1 into the paint mixing tank, adjust the speed of the disperser to 500r / min, add 1.0g of Orotan731A and 0.15g of Tego Foamex1488 in turn and stir for 5min. Add 0.5g of Add 031WUF40, 10g of mica powder, 15g of talc powder, 20g of MH-T70, and 2g of iron black in sequence, adjust the speed of the disperser to 1300r / min, and stir for 30min.

[0054] Reduce the speed of the disperser to 900r / min, add 1.0g A-801, 10.2g water, 0.15g TegoFoamex1488, stir for 15min and then discharge.

Embodiment 3

[0056] Add 35g of emulsion 1 into the paint mixing tank, adjust the speed of the disperser to 600r / min, add 1.5g of BYK-190 and 0.25g of BYK-024 and stir for 5min. Add 1.0g of Add 031WUF40, 25g of mica powder, 15g of talc powder, 10g of MH-T70, and 5g of iron black in sequence, adjust the speed of the disperser to 1500r / min, and stir for 30min.

[0057] Reduce the speed of the disperser to 800r / min, add 0.6gA-801, 6.4g water, 0.25g BYK-024, stir for 5min and then discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com